Finishing a fireplace stone: natural and artificial Interior items

The fireplace is the place where you can relax along with your loved one, gather in the evening with the whole family and calmly talk. But to create a special atmosphere, which has a vacation, must be attached to the maximum effort. The final stage of the construction of a modern furnace is the finish of the fireplace stone. From how correctly this final stage will be performed correctly, and not only the style of the room, but also the long-term operation of an important element of the interior will be further dependent.

Content

According to experts, there is no significant difference in cladding material. The main advantage of the choice of natural and artificial finishing material for fireplaces is an appearance. In second place - durability. Any natural stone can serve about 50 years, and artificial - no more than 30, so before finishing the fireplace it is necessary to decide on the material.

What is the advantage of finishing a stone

Since the popularity of the finishes of fireplaces with natural stone is growing every year, consider the main advantages of this material:

- A fireplace from a natural stone looks very original and no finishing material can so profitably emphasize the beauty of natural stone.

- Heating, natural stone does not distinguish toxins and smoke, which means the air indoors will always be fresh and clean.

- Natural facing material for fireplaces withstands any load, including physical, so the fireplace is not afraid of blows.

- It has high heat resistance.

- Natural stone can be processed and "cut" the desired form. Thus, it is possible to give individuality and uniqueness of the room.

The main advantages of artificial stone:

- "Soft" stone characteristics allow you to finish even the most complex portions of the fireplace.

- When fitting and laying the decorative stone, it will not be necessary to have a complex tool, it is enough to have an angular grinding (grinder) and a standard set of auxiliary tools.

- Due to the fact that the decorative stone is made of soft fillers, the weight of the finishing material will be significantly less than the natural stone. This means that the load on the fireplace will be minimal. Stop monolithic plates will be much easier.

- Perform the finishing of the corners and roundings of the fireplace will be simpler due to the wide range of elements.

- The cost of artificial materials for finishing the fireplaces will be much lower than the price of natural stone.

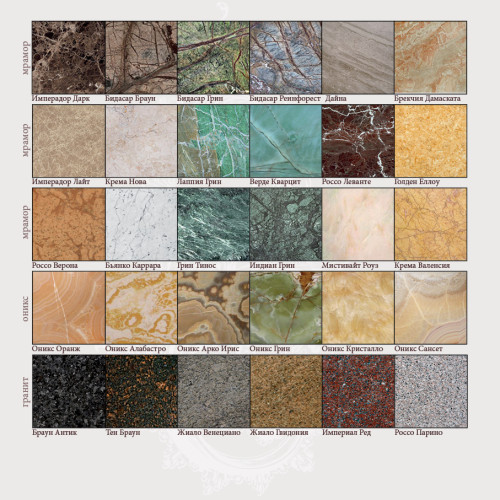

Selection of material

You can bind fireplace by any natural stone, no fundamental differences, since natural material has high strength and wear resistance. This applies to the design capabilities, but about the durability of the selected material you need to learn more. If used for cladding color marble or limestone, that in 40-70 years, such a fireplace will begin "old", and completely collapses after 600 and 100 years, respectively. Depending on the conditions and care, this figure can be reduced and increase.

Popular natural stone for finishing fireplaces - granite. It has high strength and durability. Granite is easy to handle and polish. The only lack of stone is a high cost, since granite is mined in difficult conditions.

The second material, widely used for finishing fireplaces - marble. The drawing of this stone is beautiful and unique. Along with the finish of fireplaces marble, it was customary to decorate the places of marble statuette, columns, separating steps and countertops. The cost of this natural finishing material is high enough.

In addition to granite and marble, fireplaces are facing less expensive natural materials - sandstone, tuff and limestones. Separately, I would like to draw the attention of the reader on the furnace stone (chloride), which possesses such indicators - it is good and quickly heated. If you compare this stone with ceramic brick, then its thermal conductivity exceeds the brick 2.5 times.

Fireplaces from natural stone:

Fireplace finishing with artificial materials

If there is no possibility to purchase a natural stone and bind the fireplace, then you should pay attention to decorative materials. The finish of the fireplace decorative stone looks no worse than natural natural monolith.

Popular Faceplate Materials:

- ceramic tile;

- wood;

- brick;

- decorative rock.

The main component of the decorative stone is a natural material. It can be sand, cement, perlite and various fillers.

When choosing a decorative stone for finishing fireplaces, attention should be paid to such characteristics:

- Cost of products. Depending on the manufacturer's country, the price of a decorative stone can differ significantly. Choose a domestic manufacturer - the price of the material will be acceptable.

- Quality goods must have a quality certificate.

- Pay attention to the manufacturer's company, its reputation and period of work on the market for facing of fireplaces. If the company has a long practical experience, then you can count on the purchase of high-quality facing material.

- Structure and appearance of material. If the artificial stone has a porous structure, its strength can be reduced.

- Mandatory presence of labeled packaging with a logo of the company.

- The date of manufacture finishing material. The strength of the product will score after 28 days from the moment of manufacture. If the label is indicated later date, then the product will not be durable.

- Decorative stone can be used for both facing of fireplaces and finishing the premises and doorways.

The selection of glue is an important moment when cladding fireplaces with decorative stone. Such a rule should be followed: if the facing of the fireplace is performed by a material made on the basis of cement, then the glue must have the same basis. Then the connection to the surface will be durable and high-quality. If the stone consists of a gypsum base, then for high-quality clutch it is necessary to use the same glue.

Fireplace finishing with artificial photo:

Step-by-step instructions for finishing the fireplace with artificial stone:

- If your fireplace is lined with a brick, then before facing the stone it is necessary to prepare the surface: clean the coarsely sandpaper, remove the dust and apply a primer mixture.

- It is necessary to wait until the surface will completely dry. Usually it will be needed for this at least 10-24 hours, depending on the type of primer.

- If there are irregularities on the surface of the fireplace, then it is better to first apply a layer of putty, wait when it completely will dry out, apply a layer of primer mixture and after complete drying to fit the fireplace with artificial stone.

- Take one element and attach it to the fireplace, if everything suits you, proceed to work.

- If it is planned to make a pattern, you first need to lay out all the elements, and only then start working with laying the first row.

- Start a cladding from the bottom of the fireplace from the corner, gradually moving up.

- The finish of fireplaces with artificial stone is better to perform in a seamless method.

- If there are large irregularities in some places, it is better to align them with a cement solution.

- Remember that it is necessary to work with heat-resistant materials.

- When choosing glue or plaster, pay attention to the temperature and humidity of the product.

- The seams are rubbed after complete drying of the glue, after 24 hours.

- If you use materials that are not intended for finishing the fireplaces, the heat resistance can be broken. Such negligence can spoil all the work and even lead to the emergence of a fire.

How to complete the finish of the fireplace with artificial stone, look at the video:

Natural Stone Work

Finishing the fireplace of natural materials, it is always heavy and laborious work. It is necessary to customize each stone tile in size and select the material on the shade. The work use an angular grinder or a stone machine, since it is almost impossible to manually cut the stone cutting.

Work on the fireplace of the fireplace with natural tiles:

- Prepare the surface of the fireplace - clean it from dust and secure the reinforcement grid (cells 5x5 cm).

- After the grid is fixed, it is necessary to adjust the facing stone. At first horizontally, you must lay out all the elements and perform their fit to each stone tile to be the same thickness and shade.

- If limestone laying is performed, then the thickness of the tile can not be chosen, the small discrepancies are filled with cement mortar.

- If the stone tiles have significant differences in thickness, then it is better to discard them.

- To make more convenient to work, first laid massive copies on a small amount of glue, and then less thick tiles.

- Calling can not be thrown away, but placed in inconspicuous places: inner angles in the horizontal row, the bottom row vertically.

- When it is desirable to label each element, it will not make it wrong and perform correctly laying a fireplace stone tile.

- In order for the work to be performed "on conscience", the glue should be used with the addition of elastic materials that smooth inaccuracies (especially this is relevant when heating the stone). When working with adhesive materials, it is important to work carefully and prevent the glue to the surface of the stone. If you will not get rid of the glue track forever - the surface in this place will still remain uneven.

- Start laying the first element is necessary from the bottom angle. First, the left corner is facing - bottom-up, and then the upper (horizontal) is glued. After that, you can lay out the other rows, adhering to such a rule - from the bottom-up, working on the left side to the right.

- If it is necessary to work with a massive stone slab (more than 50 cm), it is necessary to use an additional wire mount. The upper hooks are fixed for the reinforcement grid, on a freely falling wire fixed with the help of glue stone tiles. It is still necessary to use additional fastenings in the form of the letter "S" every half meter. If the stone tile is thick, then the attachments can be installed with a shorter interval.

- The final stage after finishing the fireplace with natural stone - the stamps of the seams perform 2 days from the moment of laying. Before you begin the grout of the seams, it is necessary to check the stuffing mixture on a piece of stone - if it stains the stone, then it is necessary to work extremely carefully.

Finishing fireplace stone photo:

Care rules

After the finishing work is completed, the stone surface must be treated with a special means, which will easily get rid of cement residues (it cannot be considered a knife, since it is possible to scratch a stone). Tool Save, subsequently, they can wipe the stone to get rid of traces of lime plates or mold from granite and marble.

Casual care for the fireplace from natural and artificial stone is the surface treatment with special soap solutions for stone, which effectively remove the flare and dirt, and also restore the original shine.