Penoterm for baths and saunas, features and specifications Insulation,Building materials

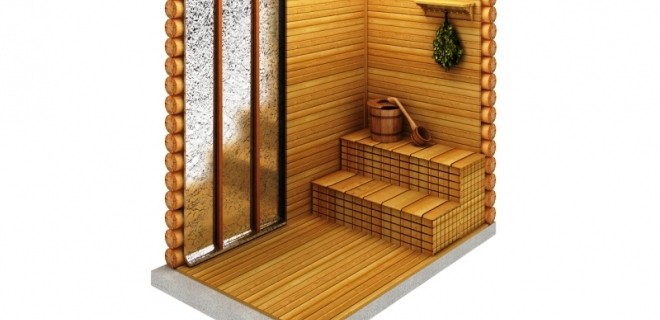

Maintaining a sufficiently high temperature in the steam room depends on the material of the walls, as well as the quality of heat insulating materials used in their insulation. The practice of the construction of bath houses shows that the insulation of walls, brick and block, in the steam room, in the rest room and the dressing room - otherwise, the conversation temperature in the room will not have a conversation.

The principle of operation of the insulation

Heat insulators can be used different, but unfortunately, each of them is not deprived of the shortcomings, especially since they are exploited in difficult conditions - at high temperatures and high humidity. Maybe this factor contributed to the rapid popularization of a new insulating material - Penuterma.

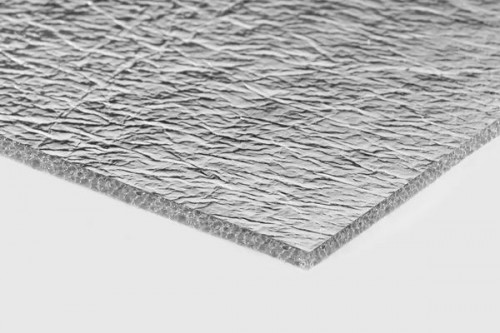

The material is produced with a foil aluminum coating or a coating of a metallized lavsan film. It is the metal-containing coating that serves as a heat mirror, otherwise, a reflective element.

SpecificationsPenutermaindicate that aluminum foil reflecting about 98% of radiant energy allows for a long time to hold a high temperature in the steam room. Installation of layer Penuterma NPP LF will significantly reduce the percentage of heat loss through the ceiling, walls, floors.

Where applies Penoterm

Depending on the use of the use, coatings with a foil surface or metallized film are used.

- Penoterm For baths and saunas is distinguished by high temperatures - cause a change in its characteristics may temperature greater than + 150 degrees.

- Layer of material Penoterm NPP The LF serves as a reliable protection of the insulation of the walls, if it is used when installing the ceiling - it will protect the design from moisture and vapor.

- The use of isolation with a foil layer in the pools will ensure heat and parosolation floors of the structure.

From those consumers who used Penoterm for a bath, feedback on the material can be heard very flattering: installation of a layer of material allows you to use in the steam room with a lower power.

Foil filthy Penoterm Ensures the wizard from the need to fix a separate layer of a very thin foil, on which defects are often formed during installation. It also disappears the need to carefully search for flashes-holes in a thin foil - the condensation formed on its surface can pass through it.

Due to its reflective ability, the insulation creates the thermos effect in the room, increasing almost a third of the energy-saving characteristics of the thermal insulation system. The effectiveness of the insulation is ensured by the ability to stop radiant heat using a screen, which is the foil surface.

SpecificationsPenuterma Allow it to be used as a resistant to high temperatures of reflective insulation, as well as under conditions of elevated temperature and mechanical loads.

Polypropylene - the basis for the manufacture of modern insulation

The basis for creating a material Penoterm NPP LE, as well as the LF serves foamed polypropylene. The advantage of polypropylene are:

- low thermal conductivity coefficient;

- not a tendency to absorb water;

- the ability to resist with tensile and compressive loads.

Such characteristics allow the use of material in saunas, baths, in the "warm floors" systems.

The brands of the foil insulation, their characteristics and properties

ManufacturerPenuterma Releases a variety of insulation of different purposes from foamed polypropylene.

- When installing the "warm floor" systems used Penoterm NPP LP, on its laveva coating, a special markup is applied on which heating elements are stacked.

- Penoterm NPP LE serves for sound insulation and applied when installing floors.

- Penoterm NPP LF is designed for thermal insulation and parosolationIt can be operated at a temperature - 40 / +150 degrees. The reflection coefficient is striving for 90%, water absorption - amounts to only 0.7% per day. The thermal conductivity of the material is 0.03, and the thermal shrinkage at high temperatures in the range from 1 to 3%.

Reduce heat transfer layer after full thickness skin promotes steam material if using 3 mm insulation its coefficient equals 0.7, then with increasing thickness up to 10 mm it will be equal to 0.9.

Coefficient water vapor permeability material equals 0.001. As a part of for the manufacture includes antipyretics, sheathed in fire space heater does not contribute to the spread of fire and prevents extinguish source of fire.

Flammability material temperate certificate Penuterma It confirmed the low level of toxicity and its material belongs to the category of low hazard to humans in case of fire.

BuyPenoterm for bath thickness can be from two to ten millimeters. Sale rolls material is at a thickness of 2 to 5 mm - 25 m in length, 8 to 10 mm - length 15 m width of material of any thickness - 1.2 m thickness of insulation is chosen depending on the thickness of the walls:.. Are thinner than , the thicker layer of insulation required. For block and brick walls experts recommend purchase insulation thickness of 8 to 10 mm.

Rules and procedures for the installation work

Note that the pricePenuterma for a bath is quite affordable, and easy installation as that to fulfill his own hands can a person with no special training.

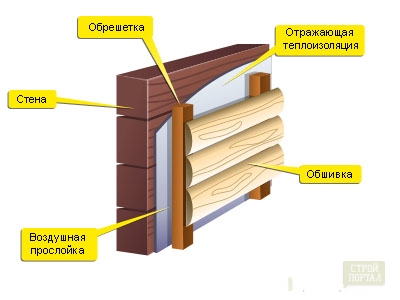

- Fixing insulation made along the ceiling or vertically on the wall, with the setting of the cloth on the floor.

- The panels are laid overlapping foiled layer inside.

- they are fixed stapler or nails.

- Through the joint glued tape.

Next, stuffed wooden crate, it fastens linings. The board can fill either vertically or horizontally.