Refractory materials for bath Baths, saunas and pools,Building materials

Near a country house or a cottage for a full rest should be a bath. Depending on preferences, you can build a Russian bath or sauna. In its design, they are not very different and some craftsmen build a bath with such a calculation that it can be used as a steam room and as a sauna.

Content

Basically, the difference is in the heating system and furnace design. For the steam room, a furnace with refractory stones, withstanding sharp cooling. In the sauna, you can use the same stones, but they do not pour water, and they give dry pairs into the room.

Refractory materials for furnaces in the bath and sauna

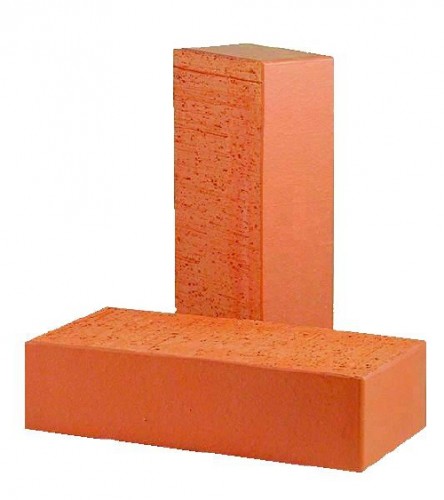

For the construction of furnaces it is necessary to use a material that is withstanding high temperatures and multiple heating and cooling. Before the construction of bath chambers and stoves for heating water, it is necessary to prepare a special refractory brick. In the construction market, refractory material for furnaces can be purchased depending on the supplied type of firebox.

For Kamenkov, natural stones are suitable: Jadeitis, serpentinite, talco chlorite. They withstand multiple heating to high temperatures and sharp cooling with water. Additionally possess healing properties. Artificial refractory materials are used for the equipment itself.

Choose material for a bath oven

Among building materials with refractory properties can be noted four types:

- basic;

- carbonistic.

All four types of refractories are capable of withstanding high temperatures, but differ in the method of manufacturing and their properties. Masters Peaks, bathing furnaces for baths and for heating of premises always give preference to chamoten brick. Apply chamotte brick and for the decorative decoration of walls of fireplaces and chimneys. His attractive yellowish color similar to sandstone has good designer properties.

Shamot or chamotte brick withstands high temperatures, not cracking during cooling. Quartz refractory material during heating can interact with metals and over time to lose its qualities. Therefore, in household furnaces and baths, it does not be used due to the presence of metal parts of partitions or built-in water heating.

Solutions for masonry refractory brick

For masonry chamotte bricks, special solutions based on bright clays with a small addition of sand are used. Chammed clay after drying well fasten the brickwork and can serve for a long time without repair.

Professional cookies in our time for masonry refractories from chamot use special heat-resistant adhesives. They have a low shrinkage and form thin seams, which positively affects the strength of the structure and its durability.

Terkesolation of walls

In the locations of the chimney and the close location of the furnace to the wall requires good thermal insulation. Special refractory materials for walls in the form of plates or plates are used to perform protection against heating. In the construction market, you can buy plates and special cardboard brands of SPGT and ICRK. They differ in their sizes and slightly by thermal insulation properties.

The marking may indicate the material to the type of material, and the number after the letters is its physical characteristics. These materials are easily applied. If necessary, you can cut holes for chimneys and other furnaces of furnaces. The plates are more durable than cardboard is used to arrange a layer between the first row of masonry furnace and a wooden floor in a bathroom.

Application of refractory materials in construction

Refractory materials are used by many centuries. From those times, as it became necessary to obtain high temperatures in the firing of ceramics or in metallurgy began to develop various types of refractory materials. Today, refractory building materials are widely used in various fields of industry, in household and for household purposes.

Among the manufacturers offering heat-resistant and refractory materials for industries and household purposes, large companies formed in recent years can be noted. The Russian market produces the supply of companies: Magnesita Refratarios, Rhirefractories, Calderys, Magnezit Group LLC. Globalization and integration is associated with some restriction of natural resources and improving the technology of production requires significant energy costs.

For mass construction in the Russian market, the brick of domestic production is used. In quality, it is practically no different from the company of the manufacturer. Its cost may be associated only with the delivery from the manufacturer to the consumer. Therefore, choosing a form of chamotte brick for a bath furnace can only be focused on the cost, because the technology of its production is strictly maintained in accordance with the standards.

What made refractory materials made

Modern production of refractory materials is based on the use of alumina, which contains aluminum and magnesium oxides. For the manufacture of high-quality refractory brick or clinker, materials are needed without impurities. When preparing a mixture for the manufacture of chammed refractories, it is strictly withstanding all proportions and drying technology.

In the process of preparing the initial mixture, a thin-fat powder-shaped and refractory clay is used. To prevent cracking during the firing, in the composition of refractory bricks, the shape can reach up to 70% of the volume. Additionally, depending on the purpose and brand, graphite or coke powder is added. In domestic purposes, bricks are used with the addition of large quartz grains. Therefore, in household furnaces and in bathing furnaces, and stamps there are bricks sandy yellowish color.

The main properties of refractory materials depend on their type and method of production. The main advantage in the ability to withstand the longer exposure to high temperatures, frequent cooling and heating. Low ability to absorb moisture, the accumulation of heat is allowed to apply them in furnaces for home heating.