Polymer floors Floors

Construction technologies do not stand still, actively develop, offering us constantly all new and new solutions in the field of interior decoration of premises. This also applies to bulk floors that have not appeared in our market. What do they imagine?

Bulk floors are a durable and durable seamless flooring, which is performed from polymers by filling.

Content

The advantages of bulk floors

Such a coating is distinguished by a lot of advantages. First of all, with the help of bulk polymer floors, you can create a perfectly smooth surface, which is not scary of mechanical damage, blows, vibrations, fire, aggressive chemicals (various solvents, acids, alkali, gasoline and oil).

Bulk floors are not subject to the negative impact of ultraviolet rays and harmful microorganisms. They are hygienic and do not accumulate dust on their surface, it is easy to clean, using any detergent, and they are completely safe for the health of others. In addition, this floor covering can be used in any room (apartment or in the office) and it has a long service life of 20 years or more.

Types of bulk floors

Bulk polymer floors are different types. They are customary to classify according to such signs:

1. Depending on the composition and the materials used, the bulk gender is isolated:

- Polyurethane floor - is made on the basis of polyurethane, which gives it good elasticity, compressive strength and stretching, stroke resistance. This is the perfect option for manufacturing workshops and premises with a large passability of people. It is easily clean manually either automatically.

- epoxy floors - the composition of such sex includes epoxy resins that allow it to use it in rooms with elevated humidity levels, for example, in the bathroom.

- Epoxy-urethane bulk floors - combine all the advantages of the two previous types of bulk floors. They have increased wear resistance and elasticity, which makes it possible to apply them in premises with a large flow of people.

- methyl methacrylate bulk floors are not so persistent as the above types, however, their main advantage is the possibility of arrangement at temperatures up to 8 degrees Celsius and the shortest possible commissioning deadlines (after 2 hours).

2. Depending on the type of the finished surface and the amount added to the sand, the floors are glossy, matte, peeled or semiamatic.

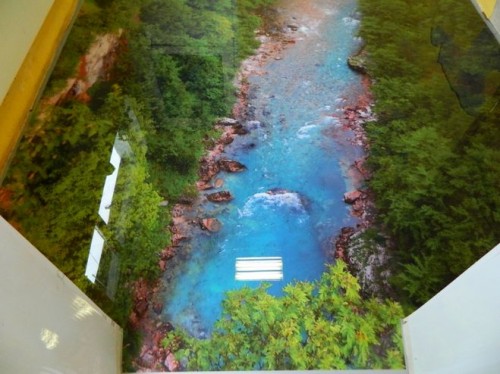

In addition, the polymer bulk floors, the photos of which we have seen above can be one-component, using several components and colored pigments with sand, sequins, etc., as well as 3-D floors with a finished pattern. The technology of arrangement of each of them has its own certain differences.

The main stages of the creation of a liquid polymer floor

Consider in more detail the creation of a bulk sex, which consists of these stages:

1. Preparation of the foundation

2. Primer and floor alignment

3. Apply the base layer

4. Decor

5. Application of the Finish Layer

6. Applying a protective layer

Preparation of the foundation

The technology of creating such an outdoor coating is quite simple. First you need to prepare the base of the floor in advance. If it is a concrete, then for its alignment you can use a cement tie of the floor or grinding machine. However, the founding can also serve as a wooden floor or even a ceramic tile. The old floor of the tree is also aligned using a grinding machine, and in the case of a tile, it is necessary to carefully follow, so that it is firmly attached everywhere. Damaged areas need to shake. Then the tile is thoroughly cleaned and degreased and only then apply soil.

Primer and floor alignment

The primer is a prerequisite for high-quality bulk sex. It is necessary in order to close the pores in the concrete or other base and limit air access. The primer can be bought at any construction store and following the manufacturer's instructions to apply on the floor with a spatula, roller or flat brush. After applying the first layer, after a certain time, the second layer is applied. At least 4 hours a maximum of 18 hours, but not later than the day, depending on the type of primer, you can proceed to applying the base layer of the bulk.

Application of the base layer

The base layer is the polymer coating itself, which is applied by the method of pouring. It is poured into the floor and distributed evenly with the help of a rocket over the entire surface. The layer of such a coating should be 1.5-3 mm. In hard-to-reach places for the coating distribution, a regular spatula is used. So, the base layer is applied and during its drying it is recommended to get rid of small air bubbles. This requires an aerial roller, which is rolled over the surface of the floor several times.

Decor

The decor of the filling floor depends solely on personal tastes and preferences. It may be simply so-called sand chips or particles, sequins, etc., which are evenly scattered at a non-frozen base surface. Also as decor, involved in acrylic or polymer paints, which are applied with roller, tassels or special pipettes or sprints. Thus, paints are mixed with each other in chaotic order, creating original patterns.

If it is 3-D floors, then as the decor element, in the same stage, the base layer is pasted with a pattern, which is pre-printed in advance in the printing house of the appropriate size. The image can be printed on a vinyl self-adhesive film that is easily glued to the base, or on the banner tissue, which is glued using the finish layer. However, before it is necessary to glue the base layer in advance to progress.

Application of the finish layer

The finishing layer is a transparent composition, which serves as a kind of fixer. It is applied in the same way as the base, after which the air bubbles are removed using an aeration roller. After graduating the process of applying the finishing layer, the floor surface is desired to be coated with polyethylene film or foil before maximum strength is achieved.

More details about the technology of creating a bulk polymer floor with their own hands on video:

.