Floor facing technology with a ceramic tile do it yourself Tile

Today, the ceramic tile is manufactured by various textures, forms, as well as in a large variety of species and color palette. It is possible for internal and external finishes, for the scenery of architectural elements, as well as for facing the floor and walls. Due to its waterproof, it is considered an excellent method of preserving the durability of walls and structures.

Content

Choosing tile

Advantages of ceramic tiles:

- It is a hygienic building material - its surface is perfectly clean;

- non-combustible product;

- has aesthetic appearance and water repellent surface;

- It is considered superpower and solid material.

Before you buy a tile, you should decide on the location of its location - it will be from this that will depend on its functional features and quality.

For example, if you decide to transform the walls of the bathroom or kitchen, you will need a tile for interior decoration. If this building material will be faced with the facade of the building, then it is necessary to use a facade option, which is more resistant to temperature drops, high humidity and does not absorb moisture. For finishing floors, a special tile is used, having increased resistance to abrasion and high density.

Types of tiled material:

- Depending on the basis - porous and dense;

- Depending on the coating - unlawed and glazed;

- Depending on the composition - extruded and pressed.

In this case, the tile may have a corrugated and smooth surface, as well as to be artificial, natural, patterned, multicolor or monophonic.

Building materials for working with tiles that may need:

- Gypsum, Olife, Rosin, Glue, Skipidar;

- synthetic mastic;

- Mesh metal mesh, which will hold the soil;

- Tol or rubberoid (if there is a cladding of a wooden surface);

- directly tile;

- Cement and sand.

Instruments:

- ruler;

- Marking cord;

- shovel plaster;

- glass cutter;

- putty knife;

- nail brush;

- chisel.

Flooring Floor Ceramic Tiles Technology

Flooring floor with ceramic tiles can be made in several ways:

- without displacement in a straight line;

- diagonally;

- In a straight line with a small displacement relative to a number of neighboring half of the tile.

Laying of sex ceramic tile includes the following steps:

- Fumbward work

- Marking

- Preparation of glue

- Direct slab tile

- Shutkish seams

Consider this activity in more detail.

Preparation of the surface and adhesive basis

From how carefully and responsibly, the specialist will suit the work will depend on the final result, life and quality of activity.

1. Initially, it is advisable to clean the surface of the buildingteril. Before laying floors with ceramic tiles, it is recommended to rub it with a wet sponge, especially if the adhesive composition is used on the basis of cement or organic mastic with a water basis.

Laying floors with ceramic tiles is made from the furthest angle in the room so that at the end of the work the specialist was at the exit and could leave it without breaking the finish.

2. The glue is applied with a riveted comb or a toothed spatula. Initially, there is not a very large amount of glue with a smooth side of the comb at an angle of 30 degrees with a slight pressure. The optimal layer is 2.5-3 mm.

3. Then the adhesive is stroken, keeping the comb at an angle of 45-75 degrees. The height of the resulting furrow should be equal to the coating look neatly.

Before starting the stacking, it is advisable to read the manufacturer's recommendations, which may indicate on the packaging with glue important moments, without taking into account which it will be quite difficult to perform work.

Flooring floor with ceramic tiles do it yourself

Some wizards when laying floors with ceramic tiles sometimes run the price on purpose, so each of us is always useful to learn how to do it yourself.

Floor laying technology with ceramic tiles is similar to wall cladding. The only thing that the material is laid out from the bottom up (ranging from the floor), and on the floor - from the long corner of the room.

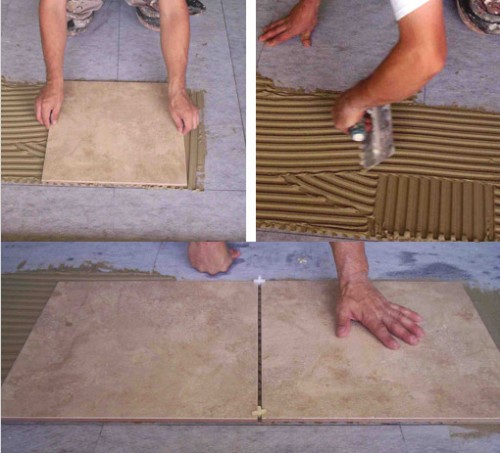

Flooring floor with ceramic tiles Photo and work process:

1. We start dragged the tile in the direction from a long corner to the entrance. For convenience, you should use a strained thread and do not forget about the level.

2. The glue covers the entire surface of the material. Make sure that the composition is distributed evenly. In order for the tile to be equal to the thread level, it is closed with a wooden hammer or handle of the trin.

3. The same is repeated with the next tile, after which crosses are put between them. Seam thickness - 2-4 mm

4. Upon completion of the work, tiles are cleaning from the adhesive composition and grout of the seams.

Recommendations:

1. If you can not position in a number of tiles in a row, then the surplus in the corners should be cut off with a tilter or a grinder. The remaining pieces are better to use in the corners, which can later be closed with a cabin, rack or locker.

2. Facing the floor with ceramic tiles, the price of which is not small to be correctly melted. During the acquisition of the material, it is necessary to add 10% of the tiles from the total number - all this is spent on trimming.

3. If the tile has a complex texture that involves docking and fit, then during the purchase it is necessary to add 15-20% of the material.

Since the laying of floors by ceramic tiles at a cost can not arrange someone, we suggest you to familiarize yourself with the technology of work on the floor of the floor with ceramic tiles on the video, which shows the process of laying with their own hands: