Rubber Garage: Installation Instructions Floors

The car for many owners is more than a vehicle, and a garage, not just a room, but a part of the house. Therefore, it is quite clear the desire to equip the garage in the best way to be comfortable and the owner, and his iron horse. Sad garages, dodged with old things, go into the past. Advanced motorists give the design in the style of techno.

Content

- Rubber Garage Floor Coating

- What are the types of floor of rubber

- yandex_partner_id \u003d 53889; yandex_site_bg_color \u003d 'fffff'; yandex_ad_format \u003d 'direct'; yandex_font_size \u003d 1.0; yandex_direct_type \u003d 'vertical'; yandex_direct_border_type \u003d 'ad'; yandex_direct_limit \u003d 1; yandex_direct_title_font_size \u003d 2; yandex_direct_links_underline \u003d true; yandex_direct_bg_color \u003d 'fffff'; yandex_direct_border_color \u003d 'fffff'; yandex_direct_title_color \u003d '0C77EC'; yandex_direct_url_color \u003d '000000'; yandex_direct_text_color \u003d '000000'; yandex_direct_hover_color \u003d 'CC0000'; yandex_direct_favicon \u003d true; yandex_no_sitelinks \u003d true; document.write ('');

- Composition and methods of rubber flooring

- What to choose a rubber coating

- How to perform a rubber floor

- PVC modules - a decent alternative to rubber flooring

Rubber Garage Floor Coating

The choice of flooring is important in the arrangement of the garage, because the floor in the garage is exposed to serious loads: the effects of rotating wheels and severity of the car, the influence of pronounced temperature factors and aggressive chemicals. The traditional concrete floor has a number of shortcomings: the dust, crushes, absorbs dirt and fuel oil, keeps damp, is covered with cracks and depressions. Modern high-quality materials and effective technologies for the arrangement of the floor in the garage once and will make rid of such problems and will help to contain a car in excellent condition.

Rubber floor coverings in a short time captured a wide range of applications: garages, industrial premises, offices, children's playgrounds. The most diverse flooring of the flooring is also used at the design of residential buildings, hotels, summer cafes, sports halls.

Flooring is chosen taking into account the functional destination of the room. All possible influence factors must be provided: substances in contact with floor, indoor humidity, power loads on rubber flooring.

Floor materials for the garage must comply with the following requirements:

- increased resistance to aggressive chemicals (gasoline, acid, technical oils);

- high resistance to mechanical damage;

- fire safety;

- waterproof;

- long service life.

When compared with any other floor in the garage box, concrete, ceramic or wooden, wins the coating of rubber. The advantages of using rubber coating are obvious and indisputable:

- Durability, strength, wear resistance. The rubber floor is resistant to the destroying effect of various factors of the external environment (air temperature drop in heat and frost, ultraviolet, fuel oil, acids and alkali). It has a long operational period (over 15 years).

- Waterproof. Rubber flooring has a water-repellent property, which allows you to wash the car right in the garage box.

- Soundproofing. Rubber is a material with excellent noise insulating and anti-vibration properties, there is no noise in the garage with a roll or sector rubber floor.

- Security. The surface of the rubber coating has an anti-slip effect, is resistant to icing, which provides comfort when walking in frosty or rainy weather. Such gender is not a fuel. Environmentally safe.

- Multifunctionality. Rubber flooring is intended for both indoors and open areas.

- Easy styling rubber floor. The ability to be coated independently, without the help of professionals.

- Easy to care and maintain the purity of the floor. It is not difficult to wash the rubber coating of the jet of water from the hose even without using detergents.

What are the types of floor of rubber

There are various modifications of rubber flooring:

- rolls width 1.25 m;

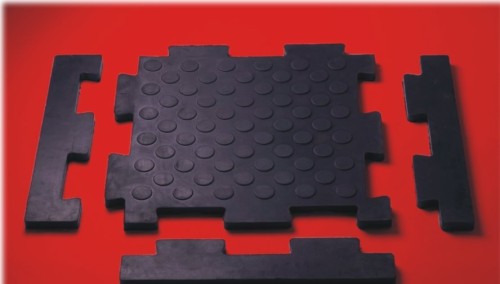

- a tile of a square or more complex curly shape with a flat or embossed surface;

- carpet on a rubber substrate with rubber sprinkle;

- bulk rubber floor.

Composition and methods of rubber flooring

The rubber garage floor is a styrene and isoprene synthetic rubber treated with thermal vulcanization method. Recently, floor coverings are mainly made from rubber crumbs. Such materials are distinguished by high wear resistance, less cost and are the optimal option for flooring in the garage.

Rubber coatings are made from the rubber crumb of the value of the fraction of 1.5-5 mm. Rubber crumbs are obtained as a result of the disposal of automotive tires. Rubber granules are attached to the floor covering the depreciation properties.

Polyurethane glue is used as a fastening agent for small rubber fragments. In some cases, synthetic EPDM rubber is used as auxiliary filler. Mineral pigments are added to the floor covering.

What to choose a rubber coating

When choosing a coating should take into account the type of transport, the presence or absence of the heating of the garage. For the assembly of the floor in the garage, the thickness of the rubber floor of the rubber flooring is 5 mm. Currently produce two types of coating based on rubber crumb: rolled and sectoral.

Rubber floor tile

The sector of rubber is a tile of 0.4-4 cm thick.

Outdoor tiles of rubber resistant to abrasion, icing, exposure to static loads and dynamic shocks, influence of vibration and aggressive chemicals. It is almost impossible to damage such a tile, it is simply indispensable for the floor in the garage. The color range of outdoor tiles from rubber is very diverse: from traditional black and gray tones to avant-garde acid shades. Recently in trend bright colors. Manufacturers care not only about the strength of the rubber coating, but also think about the tile design: shape and color.

To install it is desirable to invite a specialist. The rubber floor of the sectoral type is favorably different by a number of advantages when comparing with a rolled coating.

- First, the damaged sector of the rubber is easy and easy to restore, it is enough to replace only the spoiled segment to the new one, while the rolled floor will have to change the strip.

- Secondly, it does not require the use of adhesive compositions due to the presence of special fasteners for laying modular rubber tiles. Maximum thickness of rubber floor segments up to 4 cm

Rolled rubber floors

Rolled rubber material is made from the automobile tires served in special devices - drum-type volcanizers. For the manufacture of automotive tires, high quality rubber is used. Therefore, the floors from such durable material are characterized by elasticity, resistance to abrasion and the action of chemicals.

Due to the basic material and a special method of manufacture, such a type of flooring is obtained very durable and is characterized by high operational indicators. The rubber coating is successfully used in production workshops, and in the private sector: when laying floors, construction of parking, courtyards, country sites, equipment of open sports and sites.

But the outdoor rubber rolls acquired a special popularity with the arrangement of private garages.

Rolled rubber coating In addition to the properties of rubber tile, it is easily mounted and removed, and it looks no less aesthetic.

How to perform a rubber floor

The base for laying an outdoor rubber coating is a concrete screed. Before laying the coverage, the screed should be withstanding at least 28 days.

The cement base for which the rubber coating is stacked must have a small bias in the direction of outlet for water flow.

Laying modular tiles

With low loads on the coating, the material is not glued to the floor, but the edges of the canvases are fixed. Rubber modules are equipped with docking protrusions like puzzles. After connecting the seam modules close by sealant. When damaged, the coating is replaced by a spoiled fragment, sector or roll, without opening the main part of the floor. Lifetime of floor rubber coating at least 10 years.

For laying modular rubber coatings, careful treatment is not required, which allows the time to save time and save funds on the preparatory work.

The plates are mounted directly on the draft floor without prior alignment. And although it is worth the modular floor of rubber not so cheap, about 1,200 rubles per square meter, taking into account all the advantages, the lack of installation costs, a long operational period, in total, the flooring for the garage is required inexpensively.

Laying rolled material

Before laying a rubber roll, the base is prepared. The draft floor is carefully cleaned and ground with a special mixture consisting of polyurethane glue with turbidar. The consumption of the primer is about 300 g per m2. Rolls spread on the surface of a concrete base and leave for several days to fly back. Rubber rolled floors when laying require mandatory use of glue. Getting stuck after the "waves" disappear, and the canvas will completely straighten. Polyurethane glue treated the entire surface of the coating or only on the joints. The thickness of the roll material is usually 6 mm.

The finished floor of rubber rolls for the garage will last impeccable at least ten years.

Bulk rubber floor

Another rubber coating technology for the garage is also applied: a bulk floor, which includes rubber crumb, dyes and polyurethane glue. Ready liquid mixture is evenly distributed on the prepared base according to the instructions. The bulk rubber floor is successfully applied in Autobobes, non-residential premises with intense patency, on sports grounds.

Rubber coating can be applied by spraying method, which allows processing horizontal, inclined and vertical surfaces. For example, the rubber layer is applied at the bottom of the garage walls to protect against damage and dirt. Elastic waterproofing spraying covers bases from various materials: concrete, asphalt, wood, plastic or ceramics and even metal. The service life of bulk rubber is similar to the usual coating - approximately 10 years, subject to the compliance with technological requirements.

The rather high cost of the rubber floor covering is fully justified by the long-term operation and ease of installation.

PVC modules - a decent alternative to rubber flooring

Recently, modules are successfully used from heat-resistant PVC. This material perfectly withstands increased mechanical loads, both static and shock, not destroyed at a temperature range from - 60 to + 60c and the effects of chemical compositions, retains stability to icing and slipping. PVV coating resists burning, absorbs noise and vibration.

Outdoor PVC modules are equipped with special fastening lock elements that guarantee reliable closure of sectors when laying.

The modules are firmly bonded among themselves on the likeness of puzzles. They are of different colors, from the usual gray and brown to bright orange and green. A variety of color row and module texture allows you to create an interesting modern design. The material from which the tile is made is environmentally friendly and is allowed for recycling.

PVC modules are used both in closed rooms and on open-air sites. Modular PVC tile can often be found in the personal garage, and in car service, and industrial premises. Caring for such a floor is the most common - wet cleaning using detergents.

Operational qualities and an excellent appearance of PVC coatings are ideally manifested in the arrangement of floors in gaming and gym, industrial premises.

Mounting the modular coating is easy to do with your own hands. PVC tiles can be submitted any surface. The modular tile is simply stacked, and the floor is immediately ready, or is glued if intensive operation is to be. The modular tile is convenient and beneficial in that the damaged areas of the coating can be easily deleted and replaced. To cover the modular tile, it is not necessary to level the floor, approach and uneven surfaces with small defects and even inclined planes. If the modules are mounted on a concrete tie, it is not necessary to wait at all when it is completely dry.

Thanks to a special advanced texture and rough surface, achieved as a result of innovative developments, the PKV modules look beautiful and have an excellent anti-slip effect.

Modular coatings from durable, durable modern materials allow creating comfortable conditions in the garage, provide easy care and car content clean.

Outdoor rubber and PVC garage covers are presented in the building materials market in a wide range: this is a huge variety of floor design options, practical, optimal quality and at an affordable price.