Formwork for fence - materials, technology, features Construction

The construction of the fence always begins with formwork. And it is not necessary to hire costly specialists for its construction, you can build it with your own hands. The main thing is to remember that it depends on the quality of the formwork, how much the fence itself will serve.

Content

Types of formwork

Formwork happens:

- Vertical, with it, you can build the surface of the sheer type.

- Wall - based on her vertical walls.

- Ceiling - on its basis horizontal walls are built.

- Architectural - such a formwork is used for complex structures.

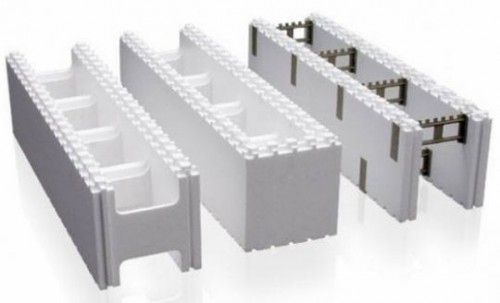

In addition, the formworks are still divided into removable and non-removable. The first, usually built from wood or hardened steel there, where the foundation should be even, and the second are very economical and more popular, they can be quickly installed and in terms of cost they go cheaper. In addition, to create a non-removable formwork, usually porous materials are used, for example, polystyrene foam and due to this, the foundation has also thermal insulation qualities.

Materials for the construction of formwork

The main task of formwork for the fence is to be smooth faces at a concrete base, and she was able to hold the huge weight of the fence. To build formwork at home needed:

- Sheet metal.

- Wooden boards.

- Rough plywood.

It would be nice to prepare all these materials in advance. Special attention should be paid to the enhancement of the formwork, for this you will need brushes with a size of 5x5 cm, but others can also be used. The boards for the connection are desirable to take 5x2 cm in size, and the plywood with a thickness of 1.5 cm. If you use a thin paneur, then during the fill of concrete there may be problems.

Preparation for the construction of formwork

Before making a formwork for a fence, you need to calculate the dimensions of the future fence.

- It is necessary to determine the height of the fence, the depth of the pit depends on it, which usually starts from 1 meter.

- Determine the length of the fence to calculate how the amount of materials it will be needed.

- Determine which materials will be used. Because if the fence is metallic, then it is not necessary for it, the foundation above the ground becomes the foundation, and if a brick or stone fence, then you will need to build a high formwork.

Foundation for formwork:

- Drop the pit with a shovel or excavator. It can be throughout the perimeter of the fence or exclusively where the formwork for the fence columns will be. The depth of the trench can be different, where there will be no pillars, it can be up to half a meter. For poles, you can create a formwork in the form of a box of polystyrene foam, without bottom and top.

- The pit must be filled with sand about 15 cm from the base.

- Sand must be tamped.

- To the board, you can perpendicularly to nail the bar and the sands of the sand, until it becomes solid as concrete.

Stages of the construction of the formwork

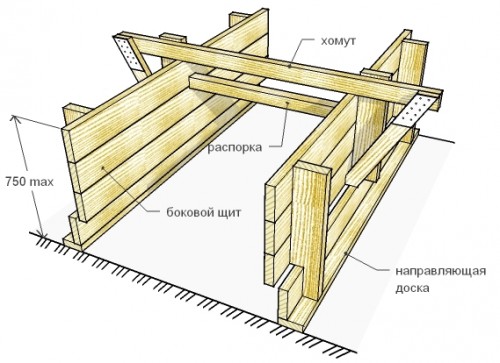

- Prepare all the materials that will be used in construction, for the backups, take wooden bars, and for walls - plywood or chipboard.

- From the edge of the pit, go to the floor of the meter and drive the wooden bars at a distance of half meter from each other. The depth of the occurrence of bars in the soil is adjusting yourself, you only need to take into account that under any circumstances should not swing.

- On one side of the pit, lower the plywood sheets on the sand is very tight. You do it from another side, and the brus from the tree will perform as a screed, they need to be attached to plywood nails. For the stability of the structure, metal connections can be used.

- Fix the bars and make sure that the formwork was indestructible, not wobble, check if there are any open spaces where there may be a solution, with a level walk along the perimeter of the structure, everything should be smooth and clear. If between the sheets of small bars, the boards can be hooked up construction. Appearance formwork anyone should not be confused, because the main thing in it - it's strength.

Pouring the foundation

If you have done everything correctly, you should leave a strong, stable formwork under the fence. So, you need to start the final stage of work - pouring the foundation. This will require reinforcing rods that need to drive a pair in about a meter apart. With welder weld the horizontal and vertical bars, so that eventually went sturdy construction. If you can not do it, invite specialists.

Further it is necessary to prepare a solution. If you have a concrete mixer, it's good, if not, take the metal container, place the cement and pour water in the ratio of 1 part cement to 0.7 parts liquid, add a solution of three parts sand, and the same amount of rubble. Mix well and add at the end of the total mixture of 1% of plasticizer. Now stir until a homogeneous mass.

Now you only have to fill in a cement mix into the trench, try to make this work for one or at most two days. And if the temperature is outside the above ten degrees, the foundation dry after approximately 20 days.

Removing formwork

I do not have any specific rules and deadlines, after which time the formwork can be dismantled. Builders say that the concrete need 28 days to completely get stronger. But all this time he is not obliged to be in the formwork. It is necessary to pay attention to the humidity and temperature. As a rule, the formwork is removed, not earlier than 10 days after the foundation was poured. If you do it before, then cracks may appear in the foundation.

Stow formwork in the opposite direction from how it was built. Professionals recommend even when erect formwork, even then to think of how it will be removed.

Milestones:

- Remove wire which pulls the construction unscrew the bolts that hold back the entire structure. Disconnect the rack and shields.

- To begin dismantling the formwork needed from top to bottom.

- The first separate grasping the edges and then removed from the base and form panels.

- Last but you need to remove tours, tows and racks, because they keep the whole design.

- The process of dismantling formwork is not fast and it can stretch for several days.

If the foundation for the fence is not a solid strip, but separate parts, then the formwork looks like separate blocks assembled together. They are installed in place with a crane.

For the same, for whom the construction seems to be unbearable, the finished structures of the formwork are sold in stores, so you can immediately begin the formation of the foundation and the construction of the fence.

New comments

Add a comment

To send a comment you need authorize.

do I need to make a pillow under the breakfast if the ground where it is planned to put the foundation - written?