Grinding wooden floor with their own hands Floors

The grinding of the wooden floor is a simple process that you can implement yourself, having some construction experience and consumables. From this article you will learn what will be needed for the repair of a wooden coating.

Content

Grinding wooden floor with their own hands

The whole process is divided into several stages:

- First of all, align the surface of the floor, then make a complete dismantling of the protective coating and eliminate the fine garbage.

- After preliminary training, go to the grinding itself. This concept includes the removal of irregularities, the defects of the floor surface and the consequences of the cyclove.

Pre-preparation of the surface is performed so that there are no diverse fuses, scratches, etc. Defects when covering the floor with varnishes.

Grinding, as well as the cyclove is a mandatory operation in the repair process. It is important to remember that an inexperienced person can damage the parquet during processing. If you are not sure about your abilities, it is worthwhile to contact a specialist. Although many people frighten the cost of grinding wooden floor, it is for them this instruction is written.

Although the last time the concept of "grinding" and "cycle" is no different, because These processes cannot be divided. Without pre-cyclovka, it is impossible to start the treatment of the floor.

Wooden Grinding Tools

Before starting work, get some materials and tools that will make it easier for the grinding process:

- The device for cycle. Not every person has this car. If you are from this number, then rent a car at a construction company.

- Cycle or other device for grinding corners and hard-to-reach places.

- Emery paper of different sizes and grainies -№40, No. 60, No. 80, №120. The number of sheets is calculated quite simple. Grinding 20 m² of parquet requires one instance of sandwich each size. You also need scissors to cut sheets.

- Putclone, which will be needed to eliminate large and small gaps between parquet boards.

- Vacuum cleaner required for cleaning the premises from garbage. It is important that before applying a varnish, the surface of the parquet was clean.

- Varnish, roller and brushes of different sizes.

Cycle hand tool made in the form of a steel plate. The edge of the base is sharpened in such a way that the surface stripping passed as easily as possible.

Circle care

During the cyclove of the wooden surface, the tool comes into an unsuitable state. In order to save his best qualities and do not bury in the grave, the cycle requires a constant subsidiary. To do this, you will need a grinding bar longer than 15 cm.

Instruction:

- Moisten the bar with water.

- Start sharpening the citner, holding it at a sharp angle of about 45 degrees.

- After processing the tool, rinse the bar thoroughly and dried.

It is best to have a diamond bar, because It is wearing enough slowly, and remains a very effective tool.

Preparatory work

Before starting work, remove all household items from the room, which will interfere with work, ranging from furniture, and ending with dining abilities. Also, pay attention to the fact that the floor does not stick out of the floor, nails and other sharp objects. To perform grinding as much as possible, it is desirable to remove all the plinths.

For those who engage in the grinding of the wooden floor in the country, it is important to take care that there is electricity in the house. The grinding machine consumes about 1.5 kW / hour, respectively, the energy source must meet the requirements.

Surface treatment

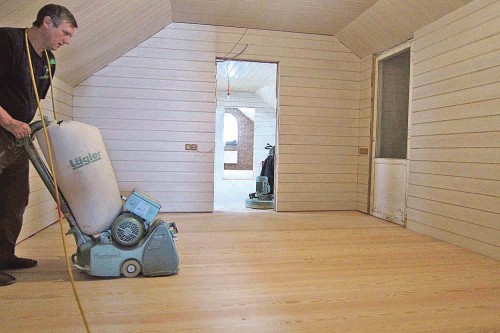

Grinding begins with room bypass along the walls. To do this, set on the grinding machine Abrasive No. 40 and go around the perimeter of the room. Repeat the operation already in the opposite direction. At the first stage, adjust the drum width in the machine, it should be 200 mm. Next, change the width to 100 mm.

To increase the efficiency of work, pass the grinding machine along the walls at an angle of 45 degrees. Then start to grind in the direction of laying parquet sheets.

A screw is present on the machine that adjusts the load of the drum. It is important to follow the operation of the engine, otherwise the machine can overload and lose its effectiveness. Watch for the voltage that goes to the car if it is not enough, the device will not work at full strength. If such a situation found you, then a little loosen the pressure on the drum and turn off all the electrical appliances from the network. If this tips do not help, then it is worth using an additional power source.

Do not forget to update abrasive material as it is wear. Abrasives with large grains perform the most difficult task - align the surface from large defects and remove contamination. Therefore, the consumption of this material will be higher.

The cyclovka process continue until the surface becomes clean.

Grinding works

After completing the preliminary work, start grinding parquet. In the process of grinding, all defects and irregularities should disappear, which occurred after the cyclove. The process must continue until the surface becomes pleasant to the touch. Parquet should not be rough and uneven.

At this stage, the abrasive sheets of smaller grain is best used, and gradually reduce it during work. Before completing the work, you will need to grind polishing and remove the remnants of putty.

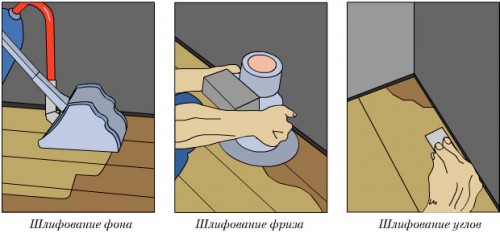

The standard grinding machine is satisfied with a large and cumbersome, so you will need such a tool like "booze". It will help to process all hard-to-reach places: corners, zones under batteries, sites behind the doors, etc. This tool uses special caution.

Latest strokes

At the last stage, the processing is better to use the abrasive material of the smallest grain itself. With it, you can remove all the minor shortcomings and defects that remained even at the previous stages of work. The size of the drum is best reduced. The quality of work is easy to check quite easily, just spend your hand over the deposited coating. If the result did not suit you, then once again go through the floor with a grinding machine.