How to check the quality of sawn timber Plumbing

Now the domestic market of sawn timber offers buyers a large range of products, which has found its use in various industries. However, the largest need for this type of production is the construction sphere. So, lumber are used to create rafter structures, for plating walls, ceilings, outdoor decoration of various buildings, as an outdoor coating, etc. Much depends on the quality of the timber used, and, above all, the final result of the work.

Content

Major criteria for choosing high-quality sawn timber

To determine high-quality lumber, first of all, it is necessary to take into account the main criteria for this choice, namely:

- timber type;

- wood grade;

- the quality of timber processing and its size.

The above characteristics directly affect the appearance, quality and price of lumber.

Type of lumber

All sawn timber is made to divide into four grades according to the GOST standards currently operating today:

- To the first grade, it is customary to attribute the highest quality lumber. They are used as a whole formulates on separate blanks, which will be used for responsible parts in various products. In particular, the transverse and longitudinal beams of the body of the car, the details of windows and doors, for laying the floors and the sheat of the walls in the wagons, etc.

- The second grade of sawn timber is usually used as a whole or as a blank for less responsible parts of products, in construction, etc., for example, for flooring, sites, wall sheat, etc.

- The third grade of sawn timber is used in construction or for the manufacture of less loaded parts of various products.

- The fourth grade is the worst-quality lumber, which, both in general, are applied to the production of little responsible details. For example, for small billets and skulls for drawers and containers.

Wood grade

The most popular wood varieties that are used for the production of sawmotherly are coniferous wood (pine, larch, fir, cedar, fir, etc.), as well as oak, ash, maple and others.

- When choosing high-quality wood, it is worth paying attention to its external characteristics, in particular the color.

- Thus, lumber produced from larch should have a dark brown shade and a rough surface, spruce or pine - a lighter shade, while they differ among themselves with the structure of wood fibers.

- Pine has a denser structure than a fir.

Accuracy of sizes

In any party you can meet different lumber size. If the length, thickness and width can be fixed, then their configuration is almost impossible. Therefore, when choosing sawn timber it is very important to pay attention to it. To do this, it is best to take with a roulette to check in place a geometry of the product.

Humidity

When choosing sawn timber, an important criterion is their humidity. Depending on the production technology, it is customary to allocate two types of sawn timber:

- made of wood with natural humidity;

- made of dried wood with artificial or natural way.

The first have a lighter shade and harder in weight dry wood. Naturally, lumber of the second species is considered better. However, for their manufacture, a lot of time will need a lot of time (2-3 years) and, accordingly, the cost of such products is significantly higher.

Natural Lumber Defects

Depending on what conditions a tree has grown and developed, it may have different defects that affect the scope of wood application. The most common defects are all sorts of bitches, cracks, a review, rot, etc.

Bitch

The bitches represent the remains of the branches that were cut during wood treatment.

- Ideally, high-quality sawn timber should not have a large number of bitch, as they negatively affect the strength of the product.

- The limit number of bitch is strictly regulated by gtostas.

- In addition, the sizes and type of bitch directly affect the degree of reduction in strength.

- It is considered the greatest defect.

Ozol

Ozol is a piece of wood that borders the crust. High-quality lumber should not have overview, the larger the length of such a plot, the worse the quality of the wood.

Cracks

Cracks are such a defect that may occur both in the process of producing lumber, in particular with improper technology of wood drying, and during wood growth.

There are several types of cracks depending on the causes of their occurrence (frosty, meticulous, otudny, etc.).

Rot

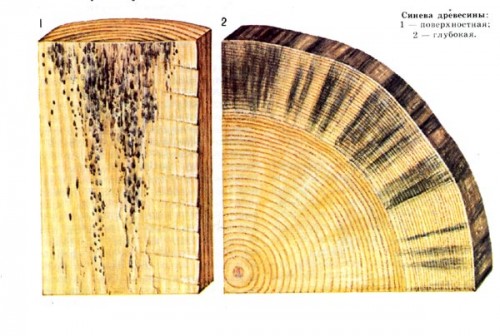

This is a defect that is caused by wood diseases, in particular, fungal lesions, and appears due to improper storage of the product. They change the color of the tree, as well as its mechanical properties.

The rot is practically not amenable to removal, so lumber struck by her immediately rejected.

In addition to the above-mentioned wood defects, you can also meet natural flaws, such as various growths, curvatures of the trunk, long-term development, etc.

How to determine visually the quality of sawn timber can be seen on the video: