Roof cover with your own hands Construction

Feels the roof? Repair it yourself. Modern materials are easy to process and will not require the cost of hiring work brigade.

Content

Along with the slate, rubberoid and tiles of various shapes and sizes, professional flooring is used to cover the roof of houses. It is a corrugated steel sheet with a multilayer coating applied to its surface, which is intended to protect it from the effects of atmospheric phenomena, light damage, etc. It should be noted that the cost of covering the roof of the roof of the corrugation will pay off its service life.

The procedure for performing work on the laying of professional flooring

When it is laying, it should be guided primarily by the instructions for its use and it is desirable to possess some specific knowledge and skills, and comply with a certain procedure:

- Preparatory work.

- Selection of material.

- Laying professional flooring.

Preparatory work

To obtain a good-quality roof that reliably protects the dwelling from the rain, snow and will withstand a strong wind (that is, the sheets will not be torn), the distances between the cage depending on the corner of the roof must be withstanding:

- an angle of less than 1500 - the distance should not exceed 10 mm;

- angle from 1500 to 3000 - the distance should not exceed 25 - 30 mm;

- an angle of more than 3000 - the distance should not exceed 50 - 60 mm;

- The roof angle is the inner corner between the skates. The distance between the rafters is desirable to be laid in the range of 600 - 900 mm.

Before laying a professional flooring, treat the impregnation lattice, which will give wood specific properties that will prolong its service life, namely resistance to rotting, etc.

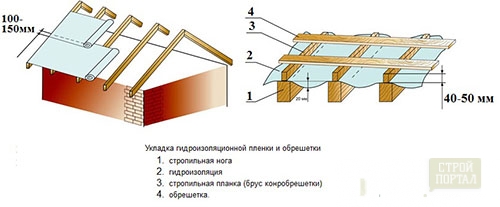

In order for the roof as long as possible to carry her service on the protection of the house, laid the waterproofing layer between the wooden roof crate. As such, rolled materials containing polymers are recommended for use.

The laying of the material starts from the lower cutting of the roof, so that the next, the upper layer formed a total of about 100-150 mm. Between the rafters, make this material to have a sagging to a depth of 150-200 mm.

The heat insulating plates are already laid, the waterproofing is equipped and everything is ready for laying a professional flooring.

Selection of material

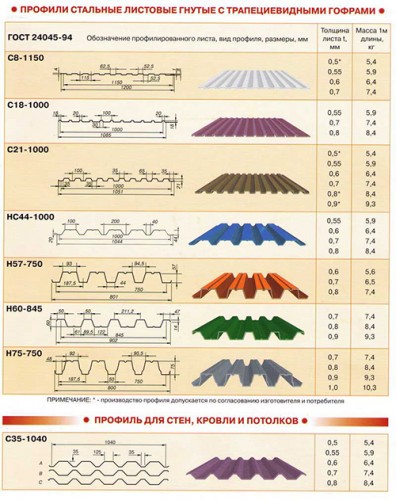

Professor is characterized by material and a geometric profile of rolled products. For the manufacture of professional flooring, steel, aluminum or copper-containing material is used. Geometric profile characteristics are as follows: height, width, length. The height is the distance from the base of the sheet to the top of the profile.

For roofing professional flooring, the use of a profile with a height of 45 mm is recommended, and the greater the roof angle, the greater the height should be. The purchase of professional flooring is advisable to conduct closer to the construction site in the construction market to avoid damage during transportation.

For work on laying a professional flooring, it is necessary to prepare the main and auxiliary tool and fasteners, and the means of protection, that is, to prepare a stepladder, scissors for metal, a shuffer, gloves for leaf metal, glasses.

Attention should be noted that if the sheets of professional flooring with nails or ordinary self-tapping screws, the result of their application after some time will be the appearance of corrosion with its further propagation at the place of attachment. As a fastener, special screws with a hex head and an installed rubber washer should be used, which serves as an obstacle of moisture to the vehicle passage through the sheet. The diameter of such screws is 4.8 mm, length 25-40 mm.

So, the roof is prepared for laying. The thermal insulation is mounted, the waterproofing is mounted, rafters and the neckenet are processed by an antiseptic, the material is bought, imported and stored, the tool is selected, the assistant is good on the street, and most importantly, the windless weather, which can be started to the main phase - the roof cover with your own hands.

Laying professional flooring

For laying a professional flooring, several ways are used, we will consider the easiest, provided that the length of one sheet is enough to close the entire length of the roof of the roof.

- The sheet of professional flooring is stacked so that Wpadina lay down on rafylin. The process begins with the lower right corner of the skate.

Before fixing the sheets, it is necessary to form an obsolence of the sheet on the edge of the roof, that is, the leaves of the sheet for the ends of the rafter, its length can be from 50 to 300 mm. This distance is determined by the brand of professional flooring, see Table 1. In order not to engage in a fit of this size, calculate the length before installing sheets.

| Professor | List departure, mm |

| NS-8, NS-10, NS-20, C-21 | 50…100 |

| NS-35, C-44, N-60, N-75 | 200…300 |

Table 1. Dependence of the leaf departure and sheet brand.

- Profile sheets are attached at the bottom, directly to the crate with 5-7 screws per square meter. This is necessary to strengthen the wind counter. Similarly, with a pitch of 125-150 mm, the sheet is fixed to extreme rafylic.

So that the sheet does not be bent under the gusts of the wind, secure several screws in the extreme rafaline. Start them to wrap in the next depression, which lies on the rafyroid. And so gradually fixes the entire sheet. And the top is the next one and so until the end of the skate. A similar operation is repeated on the other side of the roof.

- The coating technology of the roof of the corrugation is complicated with the exits of furnace or ventilation pipes on the roof surface. To bypassing such elements, specially made structures are used, which allow the maximum sealing of the joints of the joints of the pockets and pipes. The same refers to the joint of the sheets at the roof headboard.

After laying sheets of professional flooring and ensuring the sealing of pipe outlets and the joint, you can start using the installation of the drainage system.