Putty plasterboard alone Walls

When the surface is constructed by plasterboard, one of the stages will be seeding seams between sheets and the coating with a special composition of the finishing material itself. For these purposes, a putty is used for plasterboard. The features of the selection of this material and the surface of the surface and will be discussed in our article.

Content

The need for work

Immediately arises the question of the need for the process. Many wonder: Is it possible to paint drywall without putty? The answer is unequivocal - the coating of the putty surface is the mandatory stage.

This is due to the following factors:

- the presence of unkind junctions may entail the formation of new cracks;

- in the cracks may appear insects and other microorganisms;

- plasterboard is subjected to a minor shift when the temperature drops.

In addition, the application of putty will improve the adhesive properties of the surface and reduce the consumption of materials for the finish finish (wallpaper glue, a solution for tile or paintwork).

Selection of wipes

Now there is a diverse assortment of finishing materials. Putty for seammalls of drywall is classified by:

- type of binder component;

- appointment:

- consistency.

Binder component

Depending on it, putty are divided into:

- gypsum;

- cement;

- polymer.

According to experts, material made of plaster is the best option for trimming drywall. This is due to the fact that the gypsum putty consists of natural material and fillers that improve the quality of the composition.

Pluses of plaster material:

- no shrinkage;

- a smooth surface is created without problems;

- dries over the minimum time interval;

- easy preparation of the working solution.

Lack of material - low moisture resistance. Gypsum putty absorbs moisture. And after repeated drying, the surface is covered by cracks. In this regard, such material is not used in rooms with high humidity.

Cement putty is resistant to the impact of a wet environment and significant temperature fluctuations. They are indispensable when using drywall in the kitchen or bathroom.

The lack of cement mixture is the presence of a shrinkage when drying, followed by the appearance of small cracks. For this reason, the plasterboard putty is carried out in several goals.

The most versatile composition are polymer putty. They have absorbed all the best quality materials made of plaster and cement:

- the possibility of using in various premises (regardless of moisture and temperature differences);

- lack of shrinkage;

- obtaining a perfectly smooth surface (an finishing finish can even be carried out by such a putty;

- small consumption.

The lack of polymer material is a high cost. It is she who scares many people. Especially when a large area is subjected to plasterboard.

Purpose

According to this criterion, the putty happens:

- start-up;

- finish;

- universal.

The main purpose of the starting material is the elimination of seams, chips and deep cracks. It is a coarse-grained composition that can have different shades (ranging from white and ending with brown).

The finishing putty for plasterboard eliminates small defects. In most cases, it has white. This is done so that in the future you can use thin wallpaper or light shade paint.

Universal products are used both with primary alignment and finishing finish.

Consistency

Depending on the method of preparation of the workforce for trimming of plasterboard, apply:

- dry mixes;

- finished putty.

The most common option is a dry mixture. It is cheaper. The lack of dry mixes is the use of a special tool (a construction mixer or a drill with a nozzle) and a minimum amount of time when the prepared solution is frozen.

The finished putty is immediately ready for use. To obtain a composition with a homogeneous consistency, it is simply necessary to mix the material thoroughly. If the capacity is hermetically closed, the putty retains its qualities over a long period of time. "Minus" material - high cost.

When choosing a specific brand, preference should be given to the finishing material that has proven itself. According to experts, the best putty for plasterboard is Fugeenfuller. Also in demand, such materials such as Vetonit and the Volga.

The process of spitting of drywall consists of three main stages:

- preparatory stage;

- applying primer;

- preparation of the working mixture;

- coatings with putty drywall and jacks between sheets.

Preparatory stage

At this stage:

- the location of the screws is checked (they must be slightly recessed in plasterboard);

- conducting paper under the base (if it is peeled from the gypsum filler);

- all defects are cleaned with sandpaper.

In the absence of the factory edge in the drywall, it will have to create it. The extreme part of the sheets is cut at an angle of 45º. Only the implementation of this procedure will ensure efficient reinforcement of the joints.

Similar to surface

Immediately there is a dilemma, but is it necessary to rejuvenate drywall before putty? Is it possible to do without this procedure? Unfortunately, you will need to spend time and efforts to fulfill this work.

This is explained by the fact that the application of primer:

- improves the adhesion properties of the coating;

- reduces the flow rate of the finishing material (paint, glue for wallpaper);

- strengthens the seams;

- protects the surface from fungi and mold.

When buying a primer, you should pay attention to the scope of its use. To harden the surface of the drywall, only the material intended for interior is suitable. The composition of the facade primer sometimes includes components, harmful to human health.

As for the need for primer, it depends on the size of the area of \u200b\u200bthe area. In certified materials, the flow rate is indicated on the packaging container or directly on the container with the primer.

It should be noted that it is impossible to use alkyd primer. This material deforms the plasterboard, the paper part of which will be covered with bubbles.

The process of covering plasterboard walls and a primer ceiling provides:

- cleaning surface from dust (if necessary);

- filling a convenient tank with primer;

- uniform application of the composition on plasterboard and in the joints between sheets;

- drying surface;

- plasterboard coating by the second layer of primer.

The thickness of the applied layer depends on the finishing coating. When painting or sticker, the primer is applied with thin layers, when using plaster or heavy wallpaper - thicker layers.

The priming process itself is carried out by roller. Bruster is used in hard-to-reach places, in the corners and seams. It is impossible to allow a large amount of primer on a certain area. There should also be missing.

Cooking working mixture

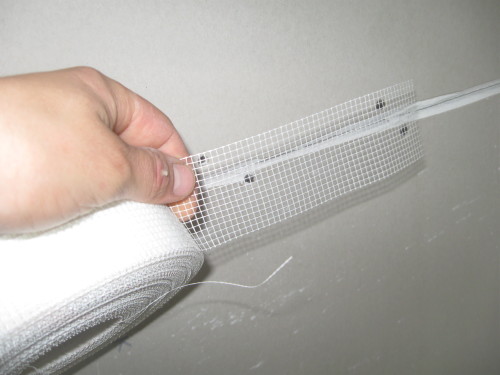

After drying, the primer can begin to put the ceiling of the plasterboard. First, all the corners and seams are covered with fiberglass grid-sickle. To carry out this process, you will not need a large amount of time, since the serpentine is self-adhesive material. The main condition - its middle should be located on the seam.

Next, you should cook the working mixture:

- in plastic bucket water is poured;

- the dry mixture is gradually falling into the water (in the center of the bucket);

- usually, 2-2.5 liters of water accounts for 1 kg of putty;

- the mixture should be soaked with water and settle on the bottom;

- with the help of a construction mixer, the putty is mixed to a homogeneous consistency;

- the finished mixture is left for 3-4 minutes;

- after secondary mixing, the putty is ready for use.

The prepared composition should be sufficiently thick. This is determined as follows. A spatula is recruited a little putty, after which the tool turns over. The composition should crawl off the spatula, and not fall or flock.

It is not recommended to do too large amounts of solution, because after 30-40 minutes there is a loss of elasticity and viscosity of putty.

Applying putty

The putty of the walls of plasterboard suggests the following actions:

- sealing seams between plasterboard sheets;

- coating with self-tapping caps;

- applying the mixture on the corners;

- finishing with finishing solution;

- surface grinding.

For high-quality application of the composition on the seams, 2 spatula are used: the first putty is recruited, the second is placed on the surface. The solution is evenly extended along the seams that are completely filled. There should be no uneven plots. Hats of selflessness are covered with a putty cross movement.

The most complex process will be the trim of the corners:

- the solution is placed on one side of the corner;

- putty grabbed;

- the second side of the angle is derived;

- a corner of aluminum is mounted on the outer corners, which makes them as strong as possible.

Application of the finish line is the final stage of the plasterboard spit. Using a wide spatula, a thin coating layer is created. As a result of this process, the surface becomes perfectly smooth. To obtain a smooth surface of the wall and the ceiling are grouped.

Video about putty drywall: