Massive floor laying technology Floors

The massive board is one of the most durable materials for laying outdoor coating. In his own way, such a board resembles a parquet, but it is much more durable and practical, as it fully consists of wood. The massive board is more stable in comparison with other floor coatings of this class to moisture changes and temperature, has a greater degree of stiffness to the loads and can withstand several springs and grinding.

Content

The laying of the massif on the floor is made after the end of the rest of the repair work so as not to spoil the material.

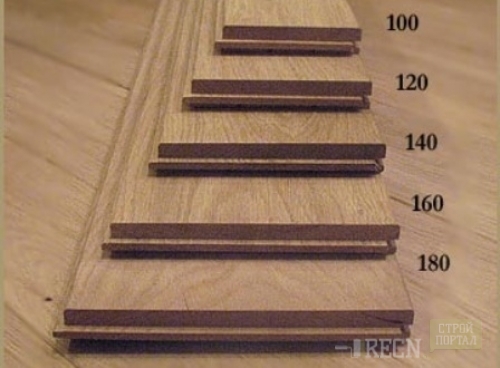

The massive board is made with applying the ridges and grooves on the edges of the board for more convenient docking. As a rule, the boards are made with a range of 120 to 200 mm and a length of 0.5 to 3 m. From the outside of the array, the chamfer is applied, thanks to which, after mounting, the coating between the boards remains a small gap, which allows you to protect an array from curvature with various kinds of deformations. . Also on the back of the board, longitudinal feeds and transverse notches are applied, which reduce the voltage of the fibers, saving them from destruction.

The cost of laying the floor from the board today is quite acceptable. However, in the presence of laying the floor from the boards, the price of which does not suit you, you can try to perform these works yourself. Moreover, laying the floorboard with their own hands is not difficult. Just follow some tips about which we will talk below.

How to choose a board

Selecting a massive flooring board is quite an important point. In addition to aesthetic properties, it is necessary to take into account the physical properties of a tree of wood, depending on which room will be styled. Alder, walnut, ash, larch, beech and ram - these are all representatives of light wood species, which are most often used to lay the floor. From pink breeds you can highlight the cherry, a pear or a cherry. However, it is worth noting that the wood of pink wood species is more capricious to a change in temperature and humidity. It poorly tolerates the air overwhelmed from the heating devices, but at the same time is afraid of big humidity.

If the laying is made in places of large moisture accumulation (adjacent bathrooms), it is better to choose a tree with a large amount of oils, for example, oak. It is also necessary to take into account the possible load on the fibers of the board. For example, if the laying will occur in the passing place: a corridor or hallway, it is better to choose solid wood, such as oak, tick or ash.

Unpacking and preparation for laying

The massive board for the floor, the laying of which is carried out, you need to properly prepare. If you properly unpack and prepare material for laying, it will avoid problems in the future. First of all, it is necessary to inspect the material for the presence of various defects. If there are no defects, then the material should be sorted, which is done both in color and in the picture. At the same time you need to define those boards that will be used for trimming.

After the materials are unpacked and sorted, it is necessary that they lie in the room where they will fit, for acclimatization and adaptation. Put the board on the stand, providing natural air circulation under it. This applies to all materials that will be used during floor laying. Before starting work, it is necessary to include all heating and air conditioning systems in the room. These systems should do about 20 degrees in the room for about 20 degrees.

Floor laying technology from board

The massive board is stacked by the same technology as laminate or parquet. Laying the first board is made by a groove to the wall, while it is fastened with the help of self-press on the front side and is covered with a plinth. Place the massive board perpendicular to the window to the window, in the direction of sunlight. For a dense connection of boards, wedges are used.

There are several methods for laying a massive board:

- laying boards on the screed;

- laying on a plywood substrate;

- mounting a massive board on a wooden coating;

- installation on carrying wooden structures;

- laying by a floating way;

- stacking for brackets;

- installation on lags.

Laying boards on the screed

- Laying of floors from boards on the screed is a fairly popular method, because it allows you to make it faster and better due to a more smooth coating, and strong. Mount the board on the screed using a special glue.

- Before laying, it is necessary to check the surface of the screed on the absence of mechanical flaws and damage that can affect the service life of the coating.

- It is also necessary to analyze the humidity of the surface. If it exceeds 6%, then it is necessary to take care of the waterproofing of the surface.

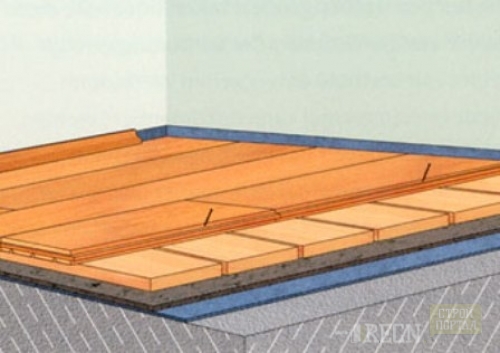

Laying a massive board on a plywood substrate

- With an increased humidity of the surface, it is more expedient to carry out the laying on a plywood substrate, which is stacked by a layer of waterproofing.

- Phaneur must be cut into small squares with a size of 0.5x0.5 meters and put on mastic or glue, consolidating with a dowel.

- After mounting the substrate, the board is started. It is necessary to do this with a two-component glue, periodically strengthening the board with special pneumoclocks.

- After laying the board slightly polished. In the event that the installation of the board is performed correctly, it will not require a long grinding.

Mounting a massive board on a wooden coating available

If you look at the flooring of the floor from the boards, whose video lessons are posted on the Internet, then you can make sure that the installation method on the available coating is quite common.

Before installation, it is necessary to depart the existing coating to align and remove the residues of paint and varnish. Laying the array is produced in the same direction as the old coating. The staple board is fixed with pneumoclocked. Quite often, a plywood substrate is laid on the old coating.

Installation according to the available wooden structures

This technology is used in wood coatings. At the same time, materials such as plywood are usually used, boardwalk and oriented chipboard.

- In front of the direct laying it is necessary to align lags by level. In this case, the maximum deviation from the plane should not be more than 2 millimeters by 2 meters.

- After alignment you need to secure slab materials. It can be a plywood or oriented chipboard. Materials should be consolidated through a moisture protective film with screws. At the same time, at least five screws should have at least five screws, and at least nine pieces should be used on the sheet. In any case, the head of the screws are drown in the stove by about 3-4 millimeters.

- Place the plate follows the direction of the future coating. At the same time, leave the gap in 2-3 millimeters between them, and the places of the plates to the walls are about 10 millimeters. The edges of the plates should not fall between lags, and should be shown on them.

- If the flooring is performed in the form of boards, then during operation it is necessary to observe the direction of laying diagonally to the direction of the existing coating. The base of the massive floor laying board must be previously treated with a grinding machine with a special abrasive ribbon.

Laying by a floating method

This method of laying is a mounting of array boards among themselves, which reduces their close contact with the draft floor. Due to this, the coating becomes more durable.

In this way, it is necessary to lay the floor in places of high humidity or if installing the floor with heating is planned. It is done quite simple. The first board is fixed as usual, and the next one with the help of anti-corrosion sams.

Laying with a bracket

This method is a type of floating laying, special aluminum brackets with compensators are used only to connect boards. This method is one of the simplest, allowing the flooring of the floor board with their own hands. It allows not to use special adhesives, making the floor more environmentally friendly.

Floor board laying on lags

- Installation on lags is used if you need to lift the floor or make a small podium. It is better to use a bar as a lag. Before installing lag, it is necessary to eliminate the floor with waterproofing by foam, polyethylene etc.

- Lags are set perpendicular to the future direction of the massive board.

- It is necessary to install two opposite lags, pull the parallel threads between them and along them to install the remaining lags.

- After their installation, chipboard or OSB sheets are installed on the lags, and a massive board is mounted on them.

Grinding and subsequent application of protective coating

- If the acquired massive board does not have a coatings, it must be processed using a belt and disk machine for grinding parquet. In addition, along the walls and in the corners of the room you need to use special angular devices.

- When the materials are polished, they need to be cleaned well with a brush or vacuum cleaner. Do not stand after this long to pull the varnish - it needs to be done on the same day.

- Varnish coating is recommended to be applied in 3-7 layers. The number of layers affects the mirror of the coating and strength. After that let boards dry.

- When the lacquer is dry, it is necessary to polish the material using the disk machine. Finally, you need to install the plinth. In this case, follow the recommendations that give manufacturers of materials.