Installation of electric boiler Climate

The electric boiler is an eco-friendly source of thermal energy. It can be used to heal water in indirect heating tanks. In addition, the boiler of this species is often used as an additional heat source. Next, we will talk about the features of the installation of this equipment.

Content

Advantages and disadvantages of the boiler

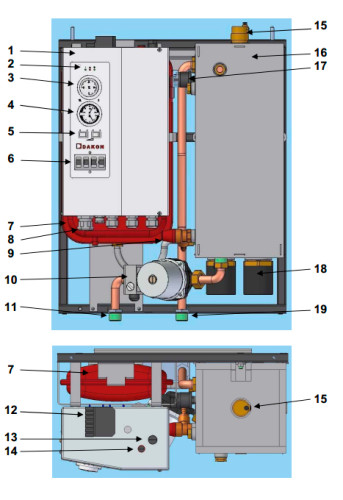

Consider in more detail the design of the electrocotel. There is a control unit, control panel and heat exchanger. The latter, in turn, consists of a tank and an electric heater. Included with the boiler in some cases expansion tank, programmer, filter, circulation pump, and a safety valve are sold.

With the help of electric boilers, almost any premises can be pulled out. Including apartments, cottages, personal homes, cottages and various trading facilities. Such installations have their advantages and disadvantages.

The pluses should include the following:

- These boilers are economical and energy efficient.

- They have a high level of efficiency.

- In addition, modern electrical boilers for home are equipped with a stepped power regulator, thanks to which it is possible to save a lot of electricity.

- Electrocotels do not throw out combustion products into the atmosphere. Therefore, when using such equipment, there is no need to equip special premises for them and do not need to mount chimney.

- The important advantages of such settings include comfortable management. In particular, the boiler is equipped with the possibility of temperature control, which automates its work as a whole. At the same time, if you wish, connect to it both street and room thermostats that allow you to make the installation of a more comfortable and economical.

- It is also worth noting the convenience of being in noiselessness, simple operation, reliability, durability, durability and a relatively low price.

- Of the advantages, it is also worth highlighting water heating. After all, such boilers can be used to heal fluid for domestic purposes, and not just for heating. Water is heated through an external cumulative boiler.

Electrocotels manufactured today are different power. So, their power varies from 5 to 60 kW. For the heating of a private building, the models of aggregates with a capacity of up to 25 kW are most suitable. If industrial and commercial objects are needed, then boilers will need with a capacity of up to 30 kW. Through electrocotes, you can organize a cascade type heating system. In it, all heating units work together. This achieves high reliability and productivity in the whole system.

It is worth considering the main disadvantages of electric boilers. First of all, it is a great consumption of electricity, which requires a lot of costs. It can be said that all the amenities are crossed out by this disadvantage. The operation of the electrocotel in the aggregate is more expensive than other heating units. But, there are ways to save on electricity and at the same time not to leave the room without heating. To do this, you can use heat-batteries of excess heat.

The disadvantages should also include the complete dependence of such aggregates from power supply. When the electric boiler is selected, it should be understood that its work is completely dependent on the presence of power supply. Thus, in case of disabling or interruptions, the boiler operation will be stopped, which is especially critical in winter. When using electrocotals as the main source of heat, you need to think about an alternative energy version in advance so that the building does not leave completely without heating. For example, you can additionally install a solid fuel boiler or a simple wood fireplace.

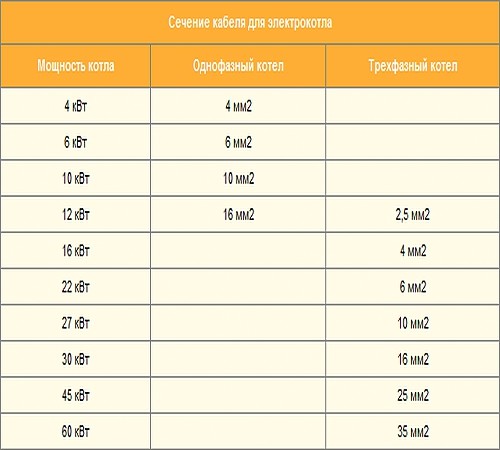

An essential minus is still the need for electrical wiring. Since the power boilers are different, the wiring for their work is required to be different. You may need single-phase or three-phase meals, which depends first of all from the power of the unit. Therefore, it is necessary to foresee in advance so that the electrical wiring is required in the building. It is easier to do in the house under construction. As for the already constructed buildings, it is possible to compatibility problems with an electrocallion with an existing power grid.

Principle of operation of electrical units

The principle of operation of electrocotals is to transform electricity into thermal energy. This is due to the operation of the electric heaters of the tubular form. These details are usually mounted in the heat exchanger tank. Due to their work, heating the heat carrier circulating in the heating system. Modern boilers are equipped with everything necessary to control the work. In particular, special control units are installed for this purpose.

Immediately heating is controlled by a room regulator, which is able to respond in a timely manner to a change in the room temperature. When triggered, the boiler begins to warm. The circulation pump ensures the necessary control of heating at home. According to the existing amount of heat indoors, the inner temperature sensor supports the desired temperature of the coolant. When the desired temperature is reached, the boiler turns off automatically, and after a while the circulation pump is also turned off.

There are several regulators and indicators on the front side of the aggregate. In particular, there is a power indicator and inclusion of heating, as well as a retainer that allows you to monitor the temperature of the coolant. Due to the presence in the design of the room regulator, you can not only monitor the heating of the room, but also save up to 27% of electricity. The operation of heating is impossible without a circulation pump, thanks to which the coolant moves throughout the system.

Electrocotels that are produced today are equipped with special fuses. Therefore, the unit will not turn on until the pressure of the coolant reaches the working value. Monitoring this process is carried out by means of a duct sensor. If the pressure exceeds the allowable, the special valve will work, which will reset it. Using the thermal switch, the heating unit is protected from overheating.

Connecting boilers to the power grid through the protective shutdown device. In addition, the shutdown automaton is necessarily used, thanks to which the unit itself is turned off when the voltage value exceeds the allowable one.

The most important element of any electrical unit is an electric heater or a tan. It is he who turns the energy of electricity into thermal. The electrocotel itself is a massive container. In addition, in its design there is a different functional and additional equipment. For example, sensors and regulators whose task is to facilitate the use of the system.

The varieties of electrocotes today there is a large number. The easiest way is the design in which the electric heater is connected directly to the heating system. In this case, the pipe with the electric heater installed in it must be removable and slightly more in diameter compared to other pipes. The ability to remove the pipe allows us to facilitate in the future possible carrying out works. So that there are no unforeseen expenses, you can equip an electric boiler with radiators. Such aggregates are usually made from steel pipes.

How to choose a boiler

Start the choice of electrocotes follows from the selection of the required power. Usually there is some rule for this - for 10 square meters. m. 1 kW power required. In addition, make sure that the unit will be equipped with an automatic power regulator. Then the boiler will need a limited amount of energy that will be enough to maintain the set temperature level. Such regulation reduces heating costs. If more smooth power adjustment is required, the installations equipped with a microprocessor control unit are used. Boilers with similar equipment usually cost more, but they still pay off due to the fact that it is spent in the process of their operation less electricity.

When choosing an electrocotel at mandatory, pay attention to its complete set. Today, almost all models that are available are equipped with an expansion tank and circulating pump. The pump, as mentioned above, allows the use of a boiler not only for heating at home, but also to heal water. Modern electrocotes have different levels of protection against various negative impacts. For example, many aggregates are equipped with a filter for cleaning the coolant, as well as several modes of operation (in winter and in summer). Some boilers are equipped with freezing protection.

How to connect an electric boiler

According to the method of fastening the electrocotels are nasty and outdoor. But the methods of installing electric boilers of different species have a lot of common.

To work, you will need:

- drill,

- building level,

- electrically conductive

- pipes

- fastening profile

- various fasteners,

- cable suitable cross section.

To connect the boiler to the heating system, you will need keys. You will also need a circuit for connecting an electric boiler, as well as the user manual that came in the kit.

In the presence of everything you need, you can start installing the electric boiler heating.

Phased order of installation work:

- Start best with marking. To do this, with a pencil and level, you should draw the place where the boiler is planned. It is best if the zone is selected, located as far as possible from the plumbing system.

- Then, with the help of a drill, the necessary holes are made in the wall. It is important that the wall material can withstand the weight of the boiler.

- After that, fix the fastening profile. With a bubble level, check the flattering attachment. After that, you can attach the unit to the wall with the help of a dowel. To install an outdoor boiler, you must first attach to the floor with a special metal stand.

- After that, it is necessary to ground the boiler. In general, some units are equipped with electronics, which does not allow them to be used without grounding. In any case, the grounding on such equipment is a mandatory rule. Without it, it is dangerous to turn on the boiler.

- It is best to remove a separate electricity supply branch for an electrical installation. The fact is that the power of the power grid may not correspond to the power of the equipment. Therefore, to the usual introductory machine to connect in this case will not work.

- To install the grounding, metal pins should be opened in the ground, connecting them together by reinforcement. This will be grounded center. In the case of connecting the unit to a separate introductory machine, you should hold a zero wire to these pins. Now the ground is ready.

- It is very important to correctly determine the cross section of the wire. It is considered the higher the required power, the greater the cross section. It also depends on the number of phases of the power grid, from which the equipment works.

- When the boiler is fixed on the wall, you can carry out the cable of the desired section from the machine. If an aggregate is used with a power up to 5 kW, it should be connected to a single-phase machine, with a power of 5 to 12 kW to two-phase. Boilers more power connected to a three-phase machine.

- To connect a single-phase boiler, you must purchase a single-phase automatic machine. The zero cable must be connected to the bus on the shield. Ground itself is supplied to a separate bus.

- After that, it is embarked on the installation next to the protective shutdown device unit. When it is completed with this, you can conduct temperature control sensors, as well as the shutdown timers of the boiler.

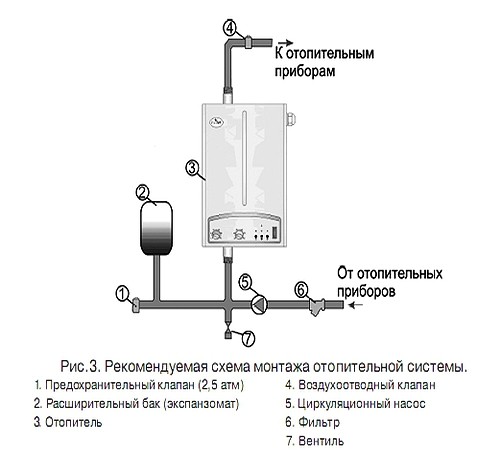

- If the pump and the expansion tank are not provided in the heating electrical boiler, then these items should be set separately. With the help of drills and fasteners, an expansion tank is attached.

- As for the pump, it is installed next to the boiler on the pipe of the coolant feed. Installation of the expansion tank has several advantages. So, it allows the use of thermal energy not only the heating of the house, but also for heating the water. In addition, thanks to him you can save electricity and avoid overheating of the boiler.

- Next, you need using metal or metal plastic pipes to connect the boiler, the expansion tank and the electric pump. After that, it is advisable to hide into special channels all the accurate wires and install a protective cover.

- When it is done, you can connect the unit to the heating system. It is attached to the pipeline with the help of couplings and flanges.

- After that, it will only be left to connect the installation to the power grid, but before you check whether there is a ground. In addition, view the correct connection of all wires. It is important that between the contacts it was about 3 mm.

After connecting and start the boiler, it is possible to include water supply. And now you need to check how the unit works to understand whether the installation of an electric boiler was carried out correctly. If necessary, excess air should be released from the system. The boiler itself needs to be checked in all possible modes. It is best to do this by creating the desired pressure using a pump and compressor.

Electric boiler: photo