DEVICE OF THE BRANCH FOUNDATION Construction

The foundation is a fundamental part of each building. It is for this part of the design that the main load of the entire structure is accounted for, so special requirements are presented to its strength. The most frequently used type of foundation for the construction of small buildings on stable soils is tape. It represents a concrete tape under the carrier walls around the perimeter and inside the structure, including all extensions. Next, we will talk about the team and monolithic belt foundation.

Content

Types of foundations

There are two types of ribbon foundations:

- Monolithic. Such a foundation is made of liquid concrete, which is poured into a specially established form-formwork. For the device of the monolithic base, reinforcement is used. The formwork contains a design from the armature of a small diameter associated or cooked with each other. Concrete for the fill of the monolithic foundation is prepared in place, if we are talking about a small structure, or bring concrete rates if the volume of work is too big. The cost of such a foundation is not too big, however, the speed of work due to the time of pouring concrete is limited.

- Collected belt foundation. This basis is collected from ready-made foundation blocks that are stacked in the trench. The advantage of the national foundation is the speed of production. With this form of the base, there is no need to construct a complex formwork, as well as lay a large number of reinforcement. To the same time, during the construction of a monolithic design, it is often necessary to wait a few days until concrete gains the necessary strength, which also stretches the construction time. Add here efforts to prepare dozens of concrete cubic meters and it will be possible to see the real advantages of prefabricated foundations.

The foundation of a small structure can be laid in one day, while having all the necessary techniques. At the same time, the cost of mounting the collection of a ribbon foundation due to the need to use special equipment (lifting cranes) increases. Also when laying the foundation blocks there is a need for their selection to link the entire ribbon. A large number of trouble can be delivered by interblock gaps in which moisture can penetrate, so they will need to be insulated, which is poured into additional costs.

What kind of belt foundation is to use in a particular case, to solve, naturally, the owner of the future building. Next, the main points in the installation of prefabricated belt foundations will be considered.

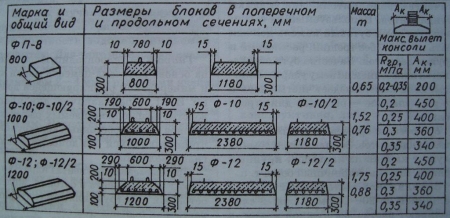

Types of foundation blocks

The foundation blocks are made on specialized enterprises. Any block must strictly comply with GOST for the following parameters:

- Block size ratio (length, width, height).

- The proportions of bulk materials in concrete (cement, sand, screening).

- Quality and configuration of reinforcement.

- Vibratory conditions.

- Concrete cooling conditions.

All these indicators of the GOST OF THE BANK BANDENT FOUNDATION are very affected by the quality of the blocks and any deviation from the requirements is unacceptable. Otherwise, there is a risk of destruction of the basis, which will cause the building collapse. For the same reason, it is impossible to use blocks made in "handicraft" conditions without quality control.

At the manufacturers' factories in the production of reinforced concrete blocks, various additives are used that affect their various properties. Thus, the addition of granite rubble to concrete to concrete gives the foundation blocks to acidic media, which makes them suitable for use in acidic soils. For use in the conditions of extremely low temperatures in concrete adds additives that increase its frost resistance.

Foundation blocks produce three main types:

- Monolithic blocks (FBS marking).

- Monolithic blocks with groove (FBS). Like the first blocks have a monolithic structure, with special grooves in the ends in which communications are paved.

- Hollow base blocks (FBP marking). They do not differ in particular strength, so it is possible to apply them only for light buildings (wooden or body houses).

From the marking of each block, you can find out its size, brand of concrete and the number of reinforcement.

Device and installation of the collecting belt foundation

Basic moments

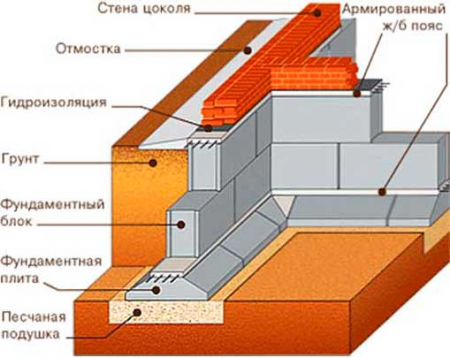

Initially, with the device of any type of foundation, it is necessary to analyze the soil. With strict compliance with all the requirements of construction technology, this type of basis can be constructed by almost all types of soil, even on bubbly. The ideal conditions for the base of blocks are soils with the content of rocks and deep groundwater. If the last condition is not respected, the basement will always be wet, despite the application of several layers of waterproofing.

Required when building a base from concrete blocks, the following operations must be carried out:

- The top of the foundation is necessarily covered with a monolithic layer of concrete and is aligned. Only after that it can be labeled brick or slag block.

- The sinuses between the foundation blocks and the soil are saturated with coarse-grained sand.

- The outer surface of the foundation is coated with a layer of waterproofing materials. It can be bitumen mastic or resin. This will be the protection of the foundation from moisture, which negatively affects the strength of concrete.

- The foundation must be inspired. For this, its outer part is frozen by polystyrene foam or other insulation materials.

- Be sure to close the joints between the blocks.

All these additional operations significantly increase the estimation of the cost of the foundation.

Installation of a belt foundation: work order

Order of work:

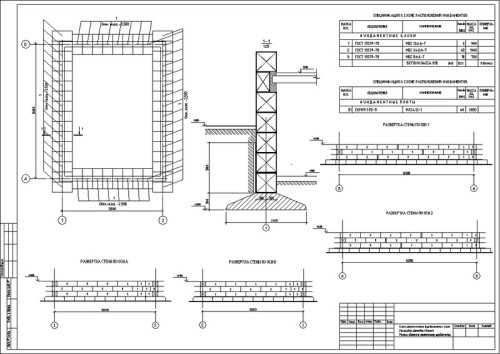

- The first thing in accordance with the project of the future house makes the markup of the site under the foundation. In order for trenches to have smooth and clear edges, it is placed with pegs and ropes stretched between them. It is necessary to try to the corners of the trenches as possible as smaller.

- Then manually or with the use of special equipment there is a trench. Its depth depends on the project of the house. The house will be harder, the foundation should be more massive and deeper. The bottom of the pit is necessary to align as much as possible, depth deviations around the entire perimeter should be minimal.

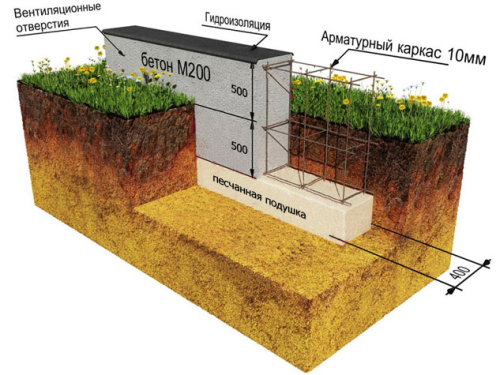

- The bottom of the trench is sleeping with river sand. The width of the sand pillow must exceed the width of the plate-pillow by 200-300 mm, and its thickness should be at least 200 mm. After the end of the skewlings, the sand is watering with water and tamper.

- The layer of the sand pillow is stacked by waterproofing. Ruberoid or dense polyethylene film can be used as the latter.

- Next begin laying blocks. The first thing for waterproofing is laid a special stove-pillow (FL). It has a trapezoidal shape, tinted from above. Due to the large area of \u200b\u200bthe lower part, such a stove reduces the pressure of the foundation to the ground, which reduces the risk of a building.

- After installing the plates, the entire surface is tightened with a reinforced belt. To do this, the bar of reinforcement is stacked on the plate surface, after which concrete is poured on top. Due to this belt, it is possible to level the surface plate surface to install the foundation blocks. Reinforcement is performed to give the entire monolithic system.

- Then begin to install blocks. To begin with, the angular blocks and those that will be on the intersection of the walls are installed. They are also called lighthouse blocks. Between them, the caprochy thread is stretched, which will serve as a reference point for all rows.

- Stacking blocks are carried out with dressing. This means that the middle of the upper row block should have to the bog of the previous one. In no case is not allowed to match the joints of the blocks of two different rows.

- The laying is performed on the cement solution, which is applied to a row and end. After mounting one of the blocks, the correctness of its position is checked with a level and plumb. If it is incorrect until the solution frozen, the unit can be corrected using a scrap. If the number of blocks is not multiple of the size of the walls, the so-called plugs use during masonry.

- In seismic zones, the assembly of the foundation between each number of blocks fit the reinforcement grid, which significantly increases the reliability of the structure. In the process of building the foundation, it is necessary to leave technological gaps for communications.

- If blocks with grooves were used during construction, the distance between them is filled with a solution.

- After the installation of all elements of the design, inter-block seams are sealed with a special water repellent composition, which will be an obstacle to the penetration of moisture on the ground floor.

- The next step is mounted upper reinforcing belt. To do this, formwork is installed on the surface of the blocks, the reinforcement mesh is placed and the solution is poured. The correctness of the surface of the reinforcing belt is checked by the level.

- A layer of waterproofing is necessarily applied to the outer wall of the foundation. In a too humid climate, several layers can be applied with an abundance of precipitation. This uses bitumen mastic. Its liquid solution can be applied using a pulverizer. To strengthen the protection against moisture, it is possible to cover the surface of the foundation of the film, however, it will further harvest the construction.

- After the end of work on waterproofing, the sinuses of the foundation (distances from the blocks to the soil layer) fall asleep with sand, carefully to his rambling. For better moisture removal, the volume can be squeezed with clay.

- The last stage of the construction of the foundation of the ribbon precast concrete is the laying of waterproofing to the upper reinforcing belt, which is already beginning to lay a brick or slag block.