Types of plastic pipes Building materials

Each of us at least once in his life made repairs in my home and stuck with the choice of pipes. Superference we know that the pipes are different. In our modern apartments and houses, the pipes are installed copper, metal or plastic.

Content

The most reliable and durable, naturally, the copper pipes are considered. But they are very expensive and almost most of the population cannot afford such pipes in their home. The most acceptable in price and quality are plastic pipes.

Pros and cons of plastic pipes

The main and most important advantage of plastic pipes, these are their durability. Plastic pipes will serve much longer than from the metal. The service life of the plastic pipe is about 50 years.

Advantages of pipes

- Corrosion resistant.

- Do not pollute the environment.

- Have low thermal conductivity.

- Lungs.

- Just simple and quickly mounted.

- Press the noise of water flow.

- The ability to install both inside and outside.

Among the shortcomings of pipes from plastic can be noted only two:

- It is impossible to use pipes in the system of fire water pipes.

- In each form of plastic pipes there is its own installation technology.

What are the types of plastic pipes

The construction market presents such types of plastic pipes:

- PVC - polyvinyl chloride;

- PP - polypropylene;

- Re - polyethylene;

- Rech - stitched propylene;

- PEX-AL-PEX - metal plastic tube.

Consider in more detail each type of plastic pipe.

PVC pipes

Used for water supply systems. They are used for mounting hot and cold water systems, as well as in other technological systems, for example, in the food industry. PVC pipes are also widely used in sewage systems.

Advantages of PVC pipes:

- To install pipes, special tools and devices are not needed, they are connected by the "cold" method by connecting them with rubber nozzles.

- Pipes are very tough, which is why connecting devices are used to connect joints.

- PVC pipes are placed in both hidden and open systems. When the pipes are laid outwardly, they give a fairly decent aesthetic appearance.

- Have an affordable price.

Polypropylene pipes

PR pipes on the construction market are sold single-layer and multi-layered. Multilayer pipes are three species, each has its own feature. The common features of polypropylene pipes are:

- Aluminum foil mount is performed by attaching it from top of the thick wall of the pipe with glue, the foil is covered with a thin propylene layer.

- Connection of three layers: pipes, protective layer and foil. The layers are mounted with each other with special holes in foil.

- The design consisting of several layers, where a layered plastic of reduced plastic is laid between two plastic layers.

Polypropylene pipes are made of four-meter length. The diameter of the plastic tube ranges in the range from 16 millimeters to 1 meter of 25 millimeters. The pipe with the fitting is connected using special equipment - the device for thermoplastic welding. There is a wide selection of PP pipes with ready-made fittings, which allows you to connect these pipes to metallic pipes. For example, in a house or apartment when installing drinking water pipes or hot / cold water pipes, as well as heating systems.

Polyethylene pipes

Designed for installation of internal and nutritional pipelines under pressure: water pipes, drainage and sewage. The value of standard pressure (working) is six atmospheres in the type of pipeline "C" (medium type) and ten atmospheres with the Type "T" (heavy).

Comparing this type of plastic pipe, it is worth noting that polyethylene pipes can be mounted even at the lowest temperature - minus 20 degrees. This is a very important advantage, especially for the repair of water pipes in the cold season.

Pipes having a diameter of 20 to 63 millimeters are combined with each other with special rubber seals or rings, as well as with the help of special couplings for electric welding.

Pipes having a diameter of more than 60 millimeters and up to 160 are connected using the joint welding.

Polyethylene pipes of two types are available:

- Low pressure (PND).

- High pressure (PVD).

Performance pipes having a diameter 50, 63, 90 and 110 millimeters are used to lay the sewage. Such pipes also have two types: low and high pressure. In Russia, such pipes produce more than 10 factories.

Pipes stitched Rekh

For higher strength and resistance to temperature fluctuations, pipes are treated under pressure. As a result of processing, the material becomes stronger. Such a process is called "stitching", polyethylene pipes themselves received the name "stitched polyethylene".

Methods for crossing pipes:

- Peroxide.

- With the help of silane gas.

- By irradiating electron flow.

- Nitrogenation.

Stitched polyethylene pipes are used for mounting water supply and heating systems. They are mounted using connecting parts. Also wide pipes are used for laying water underlook systems, snow melting systems. In order to prevent oxygen from entering, pipes are recommended when styling heating systems, additionally coated with diffusion barrier.

Metal-polymer pipes

Pipes were invented relatively recently, about ten years ago. The country that invented the metal-polymer pipes is England. Marking and abbreviated name of pipes - PEX-AL-PEX. Among the novelties of the pipes of this series are products made of materials with the addition of polyethylene, heat-resistant polyethylene and aluminum.

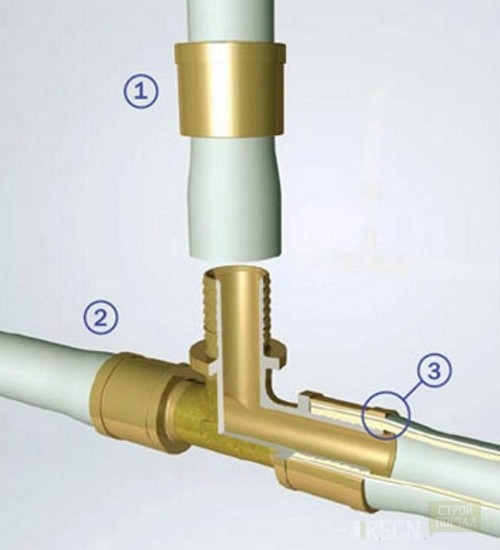

The principle of such a pipe is as follows: the basis remains the same - the cross-stitched pipe of the RC, inside which there is another layer of aluminum foil. The main idea of \u200b\u200bthese pipes is to reduce linear extension (their coefficient), as well as create a diffusion barrier.

Pipes have a complex design and consist of five layers:

- Polyethylene stitched.

- The layer of adhesive material connecting metal and plastic.

- Another adhesive layer.

- Layer of stitched polyethylene.

The main plus of metal-plastic pipes is the ability to save the shape during bend. This quality allows you to lay pipes in an open way.

The main characteristics of pipes from metalplastic:

- Stand heavy loads: temperatures up to 100 degrees and pressure almost up to 10 atmospheres.

- Used to install pipes of drinking water in the area of \u200b\u200bcatering (in sausage, dairy and other shops).

- A small amount of thermal expansion.

- Virtually no external changes and deterioration of the pipes.

- There are two ways of connection of pipes: screwing and pressing.

Plastic pipe for heating

Heating installation in small houses and apartment buildings used polymeric tube, polyethylene, polypropylene and polyvinylchloride. The main advantages of plastic pipes - the reasonable price, they are fairly easy to install (it can not afford even the master himself, without the involvement of a specialist), as well as the absence of rust and corrosion.

Among the disadvantages of tubes noted that the admission of hot water, they become "soft" can be bent, and even a little extended. Practice has shown that heating of the plastic tubes, which were hidden in the wall, in particular under the tile, during hot water curved and swelled, thereby pushed tiles and it "jumped" of the plaster. To avoid this phenomenon, plastic tube steel envelope with a thin layer of aluminum, to give the familiar plastic pipes.

For heating metal pipes are considered more suitable. They withstand the high temperature water, and they can be laid in the walls, pre-fastened by special connections. Such pipes are a little sleeker conventional, plastic and outdoor installation, they do not bend and look aesthetically pleasing.

Among the shortcomings experts note the high cost, both tubes and necessary connections.

Plastic water pipe

When installing the water pipe, we must first take into account the type of network. Pipes are divided into two types:

- Internal.

- Exterior.

In those used in the other pipes, which are designed for supplying hot and cold water.

Plastic pipes in plumbing installation has several advantages:

- Long service life. Plastic can serve decades.

- Nasty inner surface, and hence on it will not accumulate and grow over fine particles.

- Due to the absence of corrosion water passing through the pipes, it is of good quality and taste it does not change.

- Pipes from plastic, light, therefore easy to transport and install.

- Have a low price.

- Strong.

Among the disadvantages of consultants in the building supermarkets, note the following:

- When passing through the tubes, hot water, they may be slightly deformed.

- When oxygen admisted in the pipe walls, diffusion may occur, which affects the quality of the pipes and the duration of its operation can be reduced.

Plastic sewage pipes

Systems of sewage and their history is thousands of years. It is in this direction that the pipe should be high quality and serve many decades. So that the sewage cannot bring "surprises", they began to successfully apply plastic pipes from PVC, polypropylene and polyethylene for sewer systems.

Advantages:

- High durability.

- Environmental.

- Have a low price.

- Easy mounted.

PVC pipes for sewerage are made of two colors: gray and orange. These pipes are resistant to any chemically aggressive substances. Apply both internal and external sewage systems.

Advantages of orange pipes:

- Easy to mount.

- Easily cut.

- Resistant to "movement" of soil.

- Do not require corrosion protection.

- Have high resistance to temperature fluctuations.

Plastic pipes for sewage systems are classified on:

- Heavy strength class.

- Middle strength class.

- Easy class of strength.

Polypropylene pipes are gray. The most practical is characterized by increased rigidity and resistance to high temperatures. Recommend to be installed for internal sewage systems. Light in installation.

Polyethylene corrugated pipes are installed mainly in private homes and cottages. There are large diameters on sale. They differ in that they have high strength.

Among the advantages of plastic pipes for sewage sewage, in addition to all generally accepted, they allocate such: pipes are not toxic and completely exclude the occurrence of "wandering currents".

PVC pipes that are installed for outdoor sewage are divided into classes:

- S - withstand high loads (up to eight to / newtons per square meter).

- N - withstand a weaker load (up to four to / newtons per square meter).

Such pipes allocate several types:

- Lungs - lay in those places where there is no high load (lawns and sidewalks).

- Average - where average loads are provided (urban and country roads).

- Heavy - are used for laying under the roads where there is an enhanced movement of heavy vehicles (industrial areas).

Polypropylene pipes have a small weight, easy to install, have high elasticity, which allows you to quickly perform the installation of the system.

Polyethylene pipes are used for the construction of Sewerage. The main advantages of this type of pipe are ease of installation, durability. They are resistant to temperature drops, withstand frosts up to minus 50 degrees.