Cleaning wedge - how to choose and install Plumbing

Wedge valves are widely used for the complete overlap of water, wastewater and neutral liquids. The scope of operation of such valves is very wide. It covers a variety of pipelines, including housing and communal sphere, as well as water and gas supply, energy and oil pipelines, etc. To select the most suitable reinforcement of this type, you need to consider the operating temperature of the environment, pressure, as well as the necessary operation mode.

Content

Benefits and disadvantages of wedge valves

It is worth noting the following advantages of wedge valves:

- simplicity of design, which reduces the probability of breakage;

- universality of use - This shut-off valve can be used in different operating conditions, withstands various temperature modes and pressure;

- low hydraulic resistance;

- a wide dimension range - it is possible to choose the optimal option for any type of pipes;

- ability to skip the workflow in any directions.

The disadvantages of this shut-off reinforcement include:

- long opening / closing time of valves;

- significant construction heights - this refers to the retractable spindle valve;

- low maintainability when wearing sealing materials.

Features of the selection of shut-off valves

For a reliable valve service, it is necessary to choose its model in accordance with the specified operational characteristics.

It is necessary to determine:

- planned Operating Conditions - Properties of the Working Flow: Temperature Mode, Pressure, Corrosion Properties;

- bandwidth;

- required level of tightness;

- the size of the connecting flanges, the method of attaching to the pipeline;

- dimensions and body execution;

- method of managing the valve (manual or with the help of electrical, hydro, pneumatic actuator);

- safety Requirements: Explosion Proof, the ability to withstand hydraulic strikes.

Constructive execution of valves

Depending on the type of attachment of the shut-off reinforcement to the pipeline distinguish:

- welded valves;

- flange - equipped with pairs of connecting flanges, sealing rings and flanged plugs.

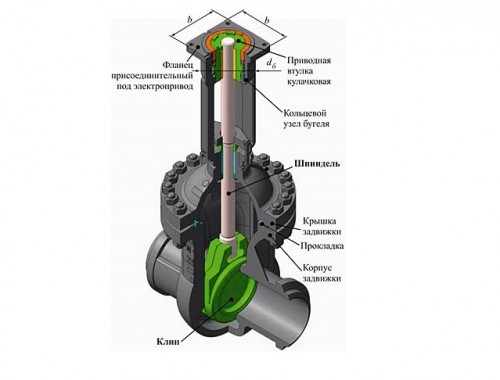

Structurally flange valve is a locking device containing a shutter perpendicular to the overlapping or opening flow. Two holes that pass the flow of the working medium through this reinforcement device are called saddles. The shut-off element with a wedge flanged valve is a detail of a wedge-shaped form, a tapering book. When closed, it covers both saddles located at a low angle to each other, as a result of which the work environment is completely eliminated. The shutter rises due to its screwing to the spindle with a thread - the rotation is transmitted from the handle of this item when manually controlled or from the drive. In the open position, there is a free flow of flow through the valve into the general system of the pipeline. In accordance with the standards, depending on the distance between the flanges, we produce long and short wedge valves.

Varieties of wedge widths

There are full-pass wedge valves - in them the diameter of the hole in the connecting nozzles corresponds to the total diameter of the pipeline. Such models are made of steel and cast iron, moreover, they are equipped with an electric drive. The narrowed wedge valves are distinguished by holes that are smaller in diameter relative to the pipe stream - such models are characterized by lower cost, but they have hydraulic resistance.

Auto-controlled models are presented on sale, as well as wedge valves with electric drive, pneumatic and hydraulic drive.

According to the nature of the movement of the spindle, wedge valves are manufactured with a retractable or stationary spindle (stock).

In retractable models, the thread of the rod and the running nut is carried out outside the design, and the spindle is the lower end combined with the shutter. When opening the valve, as a result of the commissioning of rotational movements, the rod progressively moves, its edge is put forward to the height of the shutter. Such valves are distinguished by small hydraulic resistance, ease of access to the control unit (threads need to be periodically lubricated), widely used in trunk pipelines with a constantly high flow rate.

In the locking device with a fixed spindle, the construction height does not change when opening, the thread is placed inside the design and when opening the chapel nuts on the shutter. Due to the immersion of the undercoming element in the working environment, the valve data are subject to corrosion. Due to the complexity of access to the control mechanism, such locking devices are applied much less frequently than wedge valves with retractable spindle.

View of the wedge of the catch

The following variants of shut-off devices are manufactured depending on the type of shutter:

1. With a rigid wedge - accurate correspondence of the corner of the shutter with an angle between the saddles is observed. This design provides high tightness of the valve. The disadvantages of a dense shut-off connection include the complexity of the fitting of the wedge to the saddles and the significant likelihood that the shutter can jam. In addition, the discovery of the valve may be difficult with temperature drops, as well as due to corrosion and wear of the sealing material.

2. With two-disc execution - this shutter consists of two disks bonded together at an angle forming the wedge. Such an execution of the shutter makes it possible to qualitatively seal the valve and independently set the position of the disks in relation to the saddles, despite some errors of the manufacturer of the holes. The dignity of the design should include wear resistance, ease in opening the valve and a high degree of tightness. Cleaning Wedge Hawle TwoDiscable Highly seals the pipeline and is characterized by a high wear resistance of the seal.

3. With elastic wedge - in this system, a movable disk connection is used using an elastic element. Due to this, the maximum dense contact of the saddle and the shutter is ensured, regardless of the loads and temperature drops of the working flow. Such valves are distinguished by durability.

Materials for the production of valves

We produce steel wedge flanged valves, cast-iron, as well as from alloys manufactured by casting or welding.

Valves Wedge cast-iron are suitable for operation in most pipelines, they are widely used in fire extinguishing systems, water supply, steam movement. The cast iron is characterized by low hydraulic resistance, so the working stream, including with a high viscosity, is moving freely through the open seat holes with a wedge cast-iron flange valve.

In low temperatures, it is recommended to use in the pipelines of wedge steel valves.

Rubber, fluoroplastic and polyurethane sealing rings are used as a compaction of the shut-off wedge and polyurethane sealing rings, as well as the surfacing of the metal "metal for metal" to impart corrosion resistance. For example, aVK Cleaning Latch It is made with a wedge, vulcanized with an elastomer, and its forging cast iron is covered with epoxy powder inside and outside - such reinforcement is reliably protected from corrosion.

Features of mounting shut-off valves

To ensure reliable sealing of a wedge valve, it is necessary to choose the type of gasket according to the characteristics of the working stream moving through it, while the size of the gasket and the connecting flanges must match each other.

Also, depending on the size of the valve, the diameter of the bolts is selected (according to ISO 7005).

Installation stages:

- The surface of the flanges must be cleaned of contamination and consistency lubrication.

- Install the valve between the pipe flanges, and pave the gaskets between them.

- In the holes insert bolts and slightly tighten, moving diagonally between them - by this you will achieve a parallel connection of the flanges.

- Finally fix the attachments - until the twist points specified in the instructions of the manufacturer of the gaskets.

It is also necessary to adjust locking and opening the valve (clockwise or against - according to the constructive execution) to the full opening and until the maximum torque is reached when you close in manual mode.

Wedge catch, video: