Filling a warm floor Floors

Today, few people can surprise with warm floors in a house or apartment, but, nevertheless, this topic does not cease to be relevant. And the main question is the fill of the tie of the warm floor. What materials for this use, and how to make a screed on your own, we will tell in detail in this article.

Content

Warm floor screed features

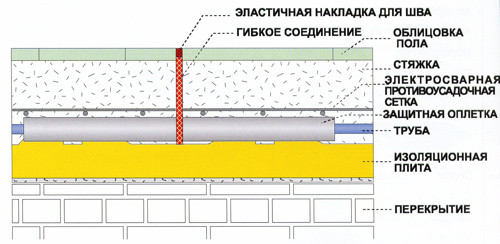

Since the warm floors act somewhat differently than the usual, the requirements for the screed will also differ. For example, the most common problem of freshly fed warm floors is the appearance of deformation gaps. This occurs as a result of the wrong placement of temperature seams. In a simple screed, the fill does not associate the installation of a monolithic plate in rooms with a large quadrature or complex forms. In such cases, the room is separated into several less large zones and delimit them with a damper ribbon to 10 cm wide.

At the same time, the area of \u200b\u200beach sector should not be greater than 30 m² at the length of the sides to 8 m, and the ratio of the length and width of the walls is not greater than 1: 2. Rooms with complex forms are recommended to divide on squares or rectangles. In some cases, intermediate lines can be made using a fine-layer of a solution depth of 1/3. After drying the concrete seams, it is necessary to pour the sealant. Only in this case can be avoided the cracking of the cement screed on the warm floor.

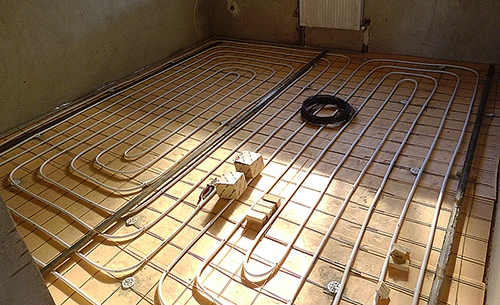

Useful advice: attach heating pipes to special V-shaped brackets or wire mesh with lining. If you plan to do a thin layer of screed in a large room with non-standard geometry, instead of the reinforcing grid, use fiber so that the load is distributed more evenly.

Preparatory work

The filling technology of the warm floor is quite simple, but that everything turned out to be qualitatively, it is necessary to carefully calculate and prepare the necessary materials. Thus, one of the important stages of the work is the installation of beacons and the preparation of cement mixture.

How to install lighthouses

Lighthouses are needed in order for the screed to be smooth over the entire area of \u200b\u200bthe room. For a reliable compound of the solution with a base in the thermal insulation layer, it is necessary to make through holes with a diameter of about 2.5 cm in the amount of 4-5 pcs. per 1 m². In large rooms, they are needed in order to prevent the screed displacement. In this case, the border is made around the perimeter of the room.

The thickness of the screed on the warm water floor is calculated so that it does not reach the door threshold, so you should start the markup from this site. At first, it is necessary to find the highest point of the floor using stretch marks or laser level - it will be a zero surface point. Depending on it, a layer of concrete concrete will be determined (at least 3 cm).

Lighthouses must be installed strictly parallel to each other so that you can make the rule as much as possible on them and stretch the solution on the floor. First, set the extreme lighthouses 20 cm from the walls, and then draw intermediate. Too much of the walls can trigger the curvature of the angle between the floor and the wall. The best way to find out the distance between the wall and the extreme lighthouse is to make it 10 cm less than the length of the rule.

If the room is big, and you need to set more than two lighthouses, first install extreme lighthouses and pull the fishing line or cord between them - it will be a reference point for the installation of intermediate elements.

Progress:

- Find the zero point of the fill of the warm water floor and make marks at this level on the opposite walls of the room.

- Fix at this level several dowels and pull the fishing line between them.

- As a lighthouse, metal profiles are very conveniently used, and their height is adjusted with wooden pars. Some experts still prefer to work "in the old manner" by setting beacons to concrete solution. If you plan to do the same, then you should find a day so that the concrete harvested, and the lighthouses securely fixed on the surface.

- Place the lighthouses so that they are strictly at the level of the stretched fishing line, retreating the walls of the wall.

- Screw the lighthouses to the floor with self-draws.

- If the profile saves between fasteners, put additional support bars.

- Knital wire screw profile to self-stakes to strengthen the fixation of beacons.

- On the perimeter of the room, pave a damper tape with a width of 5-10 mm to prevent the deformation of the future screed.

Preparation of mixes

The pouring of the warm floor can be carried out with the help of a classic concrete solution, a semi-dry mixture or modern modified compositions. Since the last prepare at home will not work, we will look at how to make a cheap and plastic cement mortar and prepare a semi-dry mixture.

Cement mortar

Cement-sand screed is the most common view. It is explained by the low cost and relatively simple work. If desired, a concrete tie will be able to perform any owner. But for the preparation of the solution is not suitable any cement - so that the screed turns out to be smooth and durable, its brand should be no less than M400. Sand should also be selected carefully - it should be very small and without clay impurities. Experts recommend using screening.

To prevent the screed into the future, a plasticizer makes it more elastic should be added to the solution. Also, the plasticizer allows to reduce the thickness of the cement layer almost halfway without loss of strength.

Usually the mixture is prepared as:

- Mix 1 cement bucket with 5 sand buckets.

- We gradually add water, stirring with a building mixer to the desired consistency.

- Test a solution for readiness - put a little mass on the floor - if it spreads, it means too much water. Ideally, the solution should be slightly broken, but overall to preserve the form.

If the solution turned out to be too liquid, you should add more cement and sand, but it is impossible to leave it so much. This can lead to loss of strength and the appearance of deformation cracks.

As a plasticizer, you can use a purchase additive for the Uponor cement. It will increase the thermal conductivity of the screed and prevent cracking. It is necessary to accurately observe the proportions - if you move to the plasticizer, it will not make the solution more elastic and durable, but only contributes to its destruction. In the case of Uponor, it should be added at the rate of 200 ml per 1 m².

There is another way to make a solution for filling the warm floor with plastic and durable concrete. It will not only improve the quality of the mixture, but also save at the cost of work. And all because the role of the plasticizer performs a normal liquid soap or dishwashing agent. Sounds a little wild, but this method is tested in many experiments and showed itself from the best side.

For the same purpose, the masters use washing powder in the amount of 1-2 tbsp. l. With a "slide" by 50 kg (th bag) cement. If you use a liquid soap or dishwashing agent, it will take about 5 l per 200 kg of cement. The only drawback is to the surface after drying, they can manifest themselves, but it is not scary, since the screed will close the finishing floor.

Liquid soaps should be added carefully - too much will lead to the fact that the solution will dry a much longer period.

Semi-dry tie

The semi-drying solution differs from the classic smaller amount of water added. For this reason, the surface is frozen much faster and has a higher strength. However, if in the case of a conventional solution from plasticizers, it is possible to refuse, then they can not do without them, as well as the reinforcing flooring.

The mixture for such a screed is made in compliance with the same proportions that for classic, however, the water is added exactly so much so that cement particles can mix with sand - no more. As a result, it practically does not give a shrinkage, much stronger due to the lack of pores, and work will take place in relative purity, which will reduce cleaning time.

Mixtures for tie

There is a huge number of mixtures for a warm floor screed, but the essence of their use is reduced to one - to ensure the maximum strength of the base, to make it as thinner as thinner and increase the thermal conductivity so that the screed does not interfere with the heating of the room.

The advantages of these compositions are that they have not only the merits listed, but are also very convenient to work. The presence of all sorts of additives and plasticizers allows them to be aligned with one movement.

For example, a mixture for pouring a warm floor Siltek F22 - can be used for surfaces under a slope before using self-leveling mixtures. Suitable for alignment of floors with drops in height of 5-40 mm. It can also be used to repair damaged screeds.

Floor Floor

Now, when the beacons are placed and a cement solution is prepared, you can start the pouring of the warm floor with your own hands. By the way, if you work alone, you should not knead a large amount of solution at once, because there is a high probability that you will not have time to completely spend it before it freezes.

Progress:

- Start work from the wall opposite to the front door. Apply a part of the solution between the beacons, put the rule on them and stretch it towards yourself, aligning the layer. Thus, walk along each "sector", separated by lighthouses, but leave yourself a place to exit the room.

- Ensure that emptiness is not formed in the solution - they will reduce the strength of the floor. To get rid of them, vibrating plates are used or simply pushed the solution to the base. If you do not use a homemade cement-sandy solution, but a highly efficient purchased mixture with plasticizers, it is not necessary to calculate the screed.

- From the first time, you are unlikely to do the perfectly reasonable reason, so it will be worth thinking about the acquisition of self-leveling mixtures for pouring the first floor. Also, after drying the screed, you can smooth out small irregularities of large sandpaper.

- After you managed to pour a warm floor, you should leave it to dry it for 2-3 weeks depending on the thickness of the layer and the consistency of the solution used. To prevent too fast evaporation of moisture, concrete is recommended several times a day to spray with water. Unfortunately, not many self-taught masters, therefore, it is often a defective coating, even with a high-quality mixture and competent fill.

- After a couple of days after the fill, remove the beacons and fill out the remaining emptiness with the primer for mineral surfaces, and on top of the cement mortar. Cut the remnants of the damper tape around the perimeter of the room.

- Mix the screed again and cover with a plastic film for 2 weeks. You can do without a film, but then the screed will have to sprink 2-3 times daily. Finally, the surface hardens in a month, then it can be coated with a clean floor.

Video about the pouring of a warm floor will give you a more complete picture of the process:

Useful advice

Finally, we suggest you familiarize yourself with useful tips from specialists. They will help you spend work as high quality and in the shortest possible time. First, before pouring the warm floor in a private house, you must stack the walls and the ceiling. The floor is the "finish line" of your repair. Secondly, in some cases, it is much more convenient to make a dry tie of the floor - it has a number of advantages compared to the classic "wet". So, at any time you can get to the pipes of the warm floor for repair or replace items. Thirdly, you need to gain patience and wait for a complete drying of the concrete before you begin to work in the room.

Linoleum or ceramic tiles can be used as a fixed coating on a flat screed. Their thermal conductivity does not prevent the gender to warm up. Laminate, on the contrary, is quite cold and cannot fully transmit heat into the room.

Warm floors have long ceased to be rare not only because of their originality, but also because they are useful for health. They say, the main thing is that the legs are warm, and such floors act just a suitable way. It is only necessary to put them on and close them with a strong screed.