Pipe oven with your own hands Baths, saunas and pools,Climate

The oven from the pipe is the most economical version of the furnace. Correctly mounted, it will perfectly cope with your task, and if you approach the case creatively, it will also decorate the room. From our article you will learn how to make a stove from the pipe with your own hands.

Content

Where the homemade tube furnace is installed

Let's notify immediately - here it is not about the oven for heating a big house. It is impractical in this way to heat it. After all, in order to achieve the necessary thermal power, the oven will need a furnace of large dimensions, and this will increase both the complexity and financial costs. In the end, according to these indicators, the stove from the pipe is compared with the brick, and it will exceed it, because it is less durable. But this design is appropriate:

- in the bath;

- household buildings, such as a greenhouse, a poultry house, etc.;

- garage.

Pros and cons of the stoves from the pipe

First about the advantages:

- simplicity of design;

- easy installation;

- the ability to use different fuel;

- fast heating;

- low weight;

- quite a long service life.

And the disadvantage is one - the furnace quickly cools, so to maintain a certain temperature, it is necessary to replenish it with fuel.

Create a stove for a bath

A homemade tube furnace consists of the following main elements:

- pissed;

- fireboxes;

- kamenka;

- tank;

- smoke pipes.

For the manufacture of the furnace, an exceptionally high-quality tube is suitable, without any flaws. As a last resort, if the source material is not new, then carefully inspect it and in places where there is a rust, delete it and make a strengthen in the form of payments.

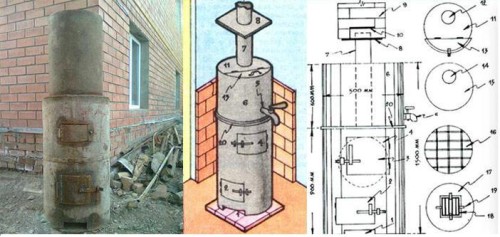

The technology of manufacturing a vertical furnace from pipes with their own hands

At the preparation stage, we carry out the following works:

- Choose a suitable workpiece. For a good stove, one and a half meters of pipe rental will be required. In this case, the optimal diameter of the pipe for the furnace is 0.5 m, the length is 1.5 m, with the walls of at least 1 cm.

- Forest with multiple wheels.

- We divide the "semi-finished product" on the part, the length of one of them is 900 cm, and the other - 600. In the first building, the furnace and the heater, and the second billet is used for the tank.

The technological process of manufacturing a furnace from the pipe with their own hands consists of 2 parts:

- production of a furnace bottom;

- construction of the hot water tank.

With a cut of a pipe with a length of 0.9 m we do the following operations:

- Cut a hole of 200 width 200, 60 cm high under the asolnik at the bottom of the future stove. Then 2 options are possible - close it with the door or insert a pull-out drawer into the hole. Choose that you are more convenient.

- We weld over the imagined metal plate of a width somewhere 150 mm round shape.

- We weld the coasters under grinding to the pipe or do in the last slot, and on the chariots we provide ears-locks.

- We place the grace in the confusion.

- We retreat from the chariots of 50 mm and cut the hole under the furnace with the parameters of 300x250 mm.

- We make the door for the furnace from the metal left after the formation of the opening and secure it on the pre-mounted loops.

- We form over the firebox of the heater using a pipe with a diameter of 300 to 350 mm. It is closed the posterior wall, and the front connect with the body with the help of welding and install the door of the same size as for the furnace.

- We perform an additional fastener for the tank, for which the wheels are welded to the top of the pipe. The minimum height of this homemade coupling is 100 mm.

We proceed to the manufacture of hot water boiler:

- we take the second blank and weld to its end the bottom with a thickness of at least 0.8 cm;

- cut into the bottom of the hole under the smoke pipe, having it closer to the rear wall;

- we weld the pipe to the bottom, and so that the water does not get into the furnace, we do it as high quality as possible;

- we place the tank on the lower half of the stove and connect these 2 parts of the stove with welding;

- we make a tank cover from a metal sheet, handling the pipe for the pipe and to replenish the tank with water;

- fix the pipe in the hole tightly using welding;

- we establish something like a watering can with a lid into a hole for water;

- cut the crane to the bottom of the tank;

- we weld to the tube the base for the brick chimney as a steel plate cut into the form of a square with a side of 300 mm, retreating from the top of the tank 350 mm.

Installation of the furnace

To avoid trouble, installing the oven, follow safety rules:

- Build a piece of concrete or bricks under the furnace, towering over a half of 200 mm.

- By installing the furnace indoors, a trimmed with a tree, remove it from the wall at a distance of at least a meter. To reduce the distance, pride the protection of the danger zone in the form of facing from refractory bricks, coatings from heat resistant plaster Or with a metal sheet.

- Place a metal sheet in front of the furnace in front of the furnace.

It remains to fill the stitch with a large pebble or ceramic insulators and work on creating a vertical furnace from the pipe completed.

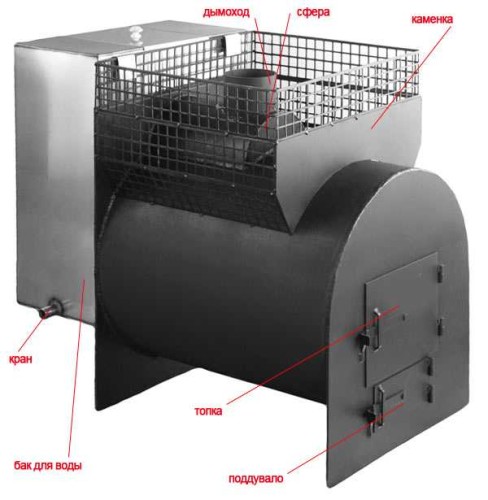

Pipe furnace in horizontal performance

The oven in horizontal design has a deeper furnace, so the room heats up faster. To make it take:

- 80 cm pipe with a diameter of 500 mm with a wall thickness of 1 cm - 2 pieces;

- 40 cm pipe with a diameter of 200 mm;

- pipe for chimney with a diameter of 114 mm;

- finished grate or fittings;

- mortise crane;

- sheet metal thickness 1 cm;

- mortise crane;

- door hinges;

- tool for working with metal;

- measuring tool;

- welding inverter, electrodes.

Get ready:

- We take the first cut of the pipe, equalize the edges, put horizontally.

- From the bottom of the pipe, we depose 133 mm (1/3 of its diameter) and carry out a direct line at this level to the intersection with the walls (chord).

- On the metal sheet, we mark and cut the rectangle. Its length coincides with the corresponding pipe size, and the width is the length of the chord. According to his center, we make a hole for grate, where they are installed. Alternatively, you can simply welcome fittings or bar.

- Insert the design into the pipe and weld.

- From the sheet metal, we cut a rectangle for registration of the front of the stove with the sides of 600x700 mm, where the smaller size is width, and the greater is height. We spill the top, cut the holes for the furnace and pondered and weld to the end of the pipe.

- We close to imagine and furnaces the doors, equipping them with pre-hinges and constipation.

- We cut out of the metal 1 more rectangle 700x900 mm and attach it to the opposite side of the pipe. The protruding part of the wall will serve as the first element of the Kamenka.

- We perform the smoke, placing it closer to the rear wall of the pipe.

- Cut the 2nd element of the heater, at the bottom of its part repeating the contour of the pipe. We weld it by retreating from the 1st wall of 40 cm.

- We take a pipe with a diameter of 200 mm, cut along 2 equal hemispheres. In one of them we closes the ends, cutting the hole in the smoke pipe almost in the middle of the same diameter as the hole on the body of the pipe.

- We place the part on the housing so that the axes of the flue holes are a bit shifted relative to each other, creating an additional zigzag at the exit of smoke, which will allow longer to keep warm in the furnace. We attach the hemisphere to the housing using welding.

- We insert into the prepared location of the pipe cut (nozzle), fix it with welding.

- Cut and weld the side walls of the heater.

- We make a basket of rod or reinforcement with a 200 mm high and put it on top to the heater.

- We weld the shelf for the tank on the back of the oven, install it, lay the stones in the basket. The oven is ready for the test.

This whole process is displayed in this video:

How to make a stove from a garage pipe

In the garage it is arranged furnaces of simple designs operating on the most accessible fuel. For some car enthusiasts, these are used oils, for others - firewood.

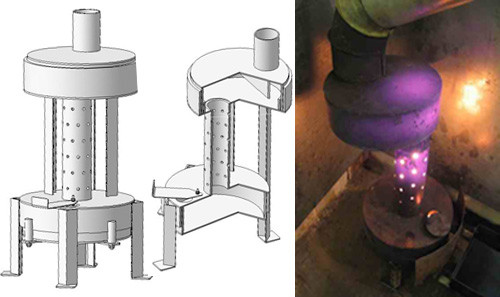

Pipe oven on working out

For the garage the most suitable oven running on the fuel in the form of working out. To implement this idea, it is necessary to purchase pipes with a diameter:

- 30 cm, 100 cm long - 2 pcs.;

- 10 cm with wall thickness from 4 to 5 mm - 2 pcs. The length of one - 80 cm, and the second - 400 cm.

The assembly of the furnace is performed in such a sequence:

- Cut the circles from the metal and we close the ends of the pipes with a diameter of 30 cm.

- In a pipe with a diameter of 30 cm, retreating from the edge of 100 mm, the hole d \u003d 10 cm drills. This is the upper part of the furnace.

- In the second pipe that serves the lower part of the furnace, first perform the same hole, then measured 250 mm from its center and make one more to replenish the furnace with fuel.

- Close the fuel hatch cover.

- By circumference of the pipe d \u003d 10 cm and a length of 80 cm we do about 50 holes with a diameter of 1 cm, having them with an interval of 5 cm.

- We screw the ends of the pipe with a plurality of holes in the blanks of a large diameter.

- We supplement the design with legs.

- A second pipe with a diameter of 10 and 400 cm long, designed for chimney, fasten with welding in the place prepared for it.

Bourgehog in the garage

Such an uncomplicated oven in the garage, greenhouse and any other economic room under the power to build even a novice liver, taking the following steps:

- Brew the front ends.

- Place the bottom of the pipe 2 holes in the form of rectangles and cut out. One of them is intended for pissed, and the second for the firebox.

- From the received waste we do the door. The edges are made up with a steel strip, we have handles and tips.

- Having retreated 100 mm from the edge of the hole for the furnace, from the inside we weld the corners and put trees on them.

- In the upper part of the structure, cut the hole under the chimney, insert the pipe into it.

- Install the stove at a permanent place and drowning firewood.

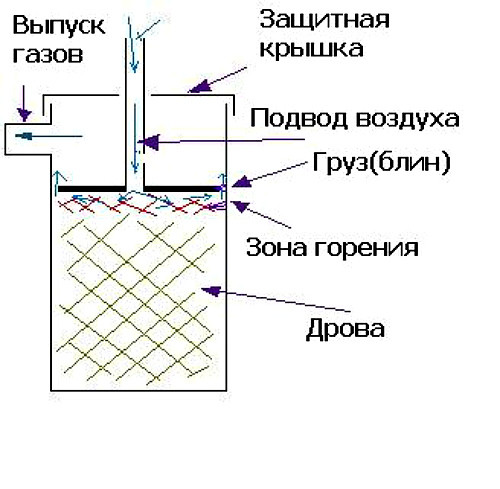

Long burning furnace from pipe in self-performance

There is one more type of furnace manufactured from the pipe is a long burning heating device. To get a reliable design, appropriate skills and responsible approach are necessary. Otherwise, an explosion is possible.

Heats this furnace gas released during the combustion of dry wood. If the firewood does not succeed in the furnace, the furnace will not work. One portion of fuel is sufficient for the process, duration of 12 hours.

From the material for the construction of such an aggregate it is necessary to have:

- steel pipe d \u003d 30 cm with a thickness of a wall of at least 0.3 cm;

- pipes d \u003d 6 and 10 cm;

- steel sheet rolling S \u003d 0.4 cm.

Installation sequence:

- Measure 1 m pipe with a diameter of 30 cm and weld to it the bottom, carved from sheet steel.

- I cut the steel circle, picking up such a diameter so that it is free to enter the pipe and we drill a hole in it d \u003d 2 cm. We weld the segment of the pipe D \u003d 6 cm and a length of at least 1 m, and on the back of the circle, we connect the welding blade from the schveller so So that they moved freely. The top of the pipes supply the damper planted on the heel with a carvings and a fixed nut-lamb. This design serves to distribute air.

- In the bottom of the furnace, cut the hole for pondering, we equip it with the door and fit.

- From the sheet, we cut the lid, bend with a hammer of the boil and we do the hole for the air distributor pipe in it. The lid must enter the pipe tightly.

- We make a foundation for a refractory brick furnace.

- Recovering from the top edge of the main pipe about 25 cm, on the side, perform a hole under the smoke pipe. With the help of welding, we perform installation in such a way that 400 mm of its length is located almost horizontally semi.

Lay into the furnace both firewood and peat, coal, sawdust. In practice, the process looks like this:

- upper cover removal, the air regulator is removed;

- load fuel to the level of the chimney;

- sprinkling the fuel with a special mixture accelerating sunbathing;

- put in place the cover and regulator;

- move the damper and throw a lit match;

- we cover the damper as soon as we note the signs of fueling.

As the fuel is rooted, the air distributor gradually lowers down, performing the role of the oppression.

The craftsmen from the people learned how to use the pipe for the manufacture of various furnaces. The authors of these videos offer their own options: