Acrylic primer: Characteristics and application Building materials

Acrylic primer is a special mixture made on the basis of latex and acrylic. This mixture is widely used to strengthen surfaces and increasing their adhesion with finishing materials. Without a primer, it is impossible to submit any housing construction, so today we will look at all types and characteristics of this substance.

Content

Specifications

The modern market of building materials offers customers a colossal number of acrylic primers for different purposes. Depending on what surface you need to cover depends on the type of primer. Consider the general characteristics of the material.

Opinions about the need for surface priming diverge. Those who believe that wallpaper or paint will be perfectly kept on the "bare" unprocessed walls, over time, are convinced of their wrong. Since acrylic primer enhances adhesion, then there is the possibility of two materials to be glued together, the unprotected surface is very quickly starting to deteriorate - the wallpaper is sprung, the paint cracks and exfoliates.

Due to its composition, acrylic primer strengthens the surface and tightly "holds" finishing materials. The principle of its work consists in creating a special plastic film on the wall, very thin, but at the same time very durable. This film does not delay the air, allowing the walls to "breathe".

Advantages

Among the main advantages of acrylic primer, the following can be distinguished:

- Strengthening the basis and increase its strength even in the case of loose and porous surfaces. Such "unreliable" coatings acquire a more dense and homogeneous structure.

- Improving adhesion (adhesion) - any finishing materials applied to the primed surface will be held firmly and served for many years.

- Water-repellent properties - the walls covered with primer becoming less susceptible to absorb moisture. This problem is especially relevant for houses from gas silicate blocks. The use of water-dispersive acrylic primer allows to significantly extend operating time, preventing the destruction of gas blocks.

- The treated coating absorbs less moisture, that is, the flow rate of the finishing finish is reduced. So, you will spend less glue for wallpaper or paint, and its color will be more saturated.

- Acrylic primers improve enamel glossy glitter.

- If you cover the dark base of the primer, you can safely apply a light paint on top of it and not be afraid that its color will be more dull.

Depending on the functional purpose of the primer, additional advantages can be distinguished. Thus, the acrylic primer in metal protects it from the formation of rust, the mixture for external work does not allow the paint to burn under the sun, etc.

Composition

The composition of acrylic primer may also differ depending on its purpose. But there are a number of basic components that are present in any of the types of mixtures.

The composition of the acrylic primer includes the following components:

- water dispersion;

- substances making the primer viscous (olive, resin);

- dyes;

- drying catalyst (the more it is in the composition, the faster the primer dries);

- auxiliary substances (chalk, marble microparticles, mica);

- specific additives depending on the purpose of the mixture (defoamer, ethylene glycol, biocide, etc.).

Depending on the operational characteristics, the percentage of one or another component may vary. The density and time of drying acrylic primer depends on the same.

Primers made on the basis of organic solvents are perfectly suitable for external finishes, since they are able to withstand the destructive effects of the environment. The mixtures based on water connections are intended for internal work. Acrylic primers of this species are not so resistant to pollution, but much more environmentally friendly and have no smell.

Consumption

Primer consumption depends on several factors:

- The nature of the surface is a porous or loose base requires a much larger amount of primer. Therefore, if you need to cover exactly such a wall, choose a mixture for porous surfaces, for example, an acrylic primer of deep penetration.

- The number of layers - one liter of universal primer is enough to cover 10-12 square meters of a conventional smooth surface with a moderate porosity in two layers. On the package of each mixture, depending on the species, the recommended number of layers is written for certain purposes. If you treat highly absorbing surfaces, for example, drywall or rough concrete, then the flow will be greater.

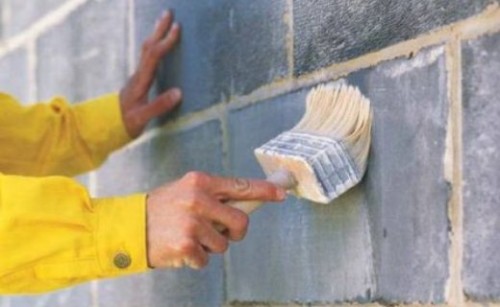

- The tool for applying the mixture - depending on what you will use to cover the wall by primer, will depend on the consumption. For example, if it works for a tassel, it will take more time and strength, but if you use the roller, it will absorb the mixture stronger, although you will save your time. Modern professional builders prefer not to use anything or other, but to work with a pulverizer.

Views

Imagine how much materials exist, from which you can build a building, and for each of them there is a suitable primer. Consider in more detail the main types of mixtures.

Universal

Universal acrylic primer is used for the facing of almost all surfaces. It is equally well to handle metal, concrete, brick, plaster and other materials. However, if you need a directed impact on one or another factor, for example, to reflect the sunlight or reinforced corrosion protection, it is better to use a specialized mixture for this purpose.

The beauty of this primer in its versatility, so if you just need to increase the adhesion of the wall of the indoor room, say, in the living room, acrylic primer under the wallpaper is suitable as it is impossible.

This type of mixtures is two types:

- Penetrating acrylic primer - can penetrate to a depth of up to ten centimeters. Thus, the adexts of the deepest layers and finishing material occurs.

- Strengthening acrylic primer - acts only on the upper base layer.

AlkudaCrylova

Alkiped-acrylic primer is used mainly to process metal and wooden surfaces. This species is one of the most suitable for the coating of the raw wood, as it scatters its structure. As a result of the swelling, ideal conditions for applying a finishing coating are obtained. In the case of metal, such a primer can generally be used as an finishing finish.

However, this type of mixtures have a significant limitation. Thus, alkyd primers cannot be processed back and plated surfaces, since the alkid in their composition will make them darling.

Metal

Since the primer is designed specifically for working with metal surfaces, it can be guess that its main advantage is to protect the material from premature corrosion. It should be known that for different metals there is also a type of primer, since they have different characteristics. For example, for aluminum, special mixtures with a high content of phosphates are more suitable. To protect the steel or surface from the black metal, it is better to apply purely alkyd or alkyd-urethane compositions.

On concrete

Acrylic primer for concrete in most cases is used in staining systems for enamel coating. The composition is necessary in accordance with the coating material and the appointment of a concrete base. For example, to process concrete floor it is best to use polyurethane or epoxy primer, and for walls - more "simple" mixtures.

Acrylic primer for walls, floor or ceiling is chosen based on a set factor, so before purchasing building materials and tools, you need to think through every step to the smallest detail. This will allow you to save not only your own money on the consumption of mixtures and spend much less time to finish, but also enjoy the fruits of successful work for many years.