Wood Antiseptic: Characteristics, Choice, Application paints and varnishes

Before carrying out any carpentry, wood is made by antiseptic compositions. This measure helps protect the wooden structures from rot, mold, the development of fungi, as well as damage by various insects. Among other things, some antisapki for wood have flame retardant properties, which helps make the material less flammable and more resistant to fires. We will tell about the types, destination and methods for using antiseptics in this article.

Content

What are the antiseptics

Classification of antiseptics for wood according to the composition of the substance

Depending on whether components are based on this or that agent, several types of antiseptics distinguish:

- Water soluble substances are often used in preventive purposes. Such compositions are treated only by those surfaces that will subsequently have direct contact with moisture or water. Choosing a similar antiseptic, it should be borne in mind that after processing the material he will need to dry for some time. In some cases, after applying the water-soluble antiseptics, the tree can crack and deform.

- Oil compositions are used where it is necessary to protect wood from moisture exposure. A minus such impregnation is its flammability, as well as an unpleasant smell that can be held for a long time. In addition, oil antiseptics change the color of the material.

- Forms based on organic solvents are used to process wooden structures and parts both outside buildings and indoors. Thin film antiseptic, covering the wood surface, performs adhesive and hydrophobic functions.

- Combined antiseptics combine several different properties. Along with the ability to protect material from fungi, mold and parasites, they also play the role of flame retardant substances. Such antiseptics for wood are called antipirens.

To choose to choose the composition for the processing of wooden surfaces, you need to take into account several factors, for example, the breed of wood and the ability of the material to absorb certain substances. The most popular wood types are divided into such types:

- Resistant rocks are distinguished by reliability, durability, weak exposure to rotting. Such materials include: pine, ash, larger core and oak.

- Medium-grained rocks have a smaller resistance to rotting processes. The mid-resistant species of wood include: fir, spruce, larch and cedar.

- Low-resistant breeds are not so reliable and durable as previous two types, among such materials you can allocate: the core of the elm, the swamp of birch, maple, beech and oak.

- Breeds that are most susceptible to grinding processes are called unstable. These include the core of Birch, Osin, Olhu, Socolawing Linden.

Depending on how well the material is impregnated with liquid compositions, wood is classified as follows:

- Low-populated trees are the beech, pine and swamping birch.

- The breeds with a moderate ability to absorb liquids: aspen, oak swamp, core of pine, maple and linden swamp.

- Supported species include oak core, birch and ash, as well as spruce.

Classification of antiseptics for appointment

Depending on what one or another composition is intended, 2 main types of antiseptics are separated:

- Preventive substances are used in the earliest stages of construction, even before wooden elements become part of any design. Wood processing by antiseptic prophylactic purposes can be carried out immediately after purchasing the desired material. Only after 1 or 2 layers of the substance are completely absorbed into the tree, it is possible to carry out the primer and painting of wooden elements.

- Therapeutic antiseptics are aimed at eliminating existing problems. If wood has been subjected to decay or was amazed by parasitic insects and microorganisms, similar compositions should be applied. Therapeutic antiseptics are used in some cases as preventive processing, if it is assumed that the design will be used under adverse conditions, for example, with high humidity.

Classification of solutions for the application

Depending on the wood breed and on the purpose of the material, it is necessary to select the appropriate composition and determine the features of surface treatment. The scope of application differ 2 types of antiseptics:

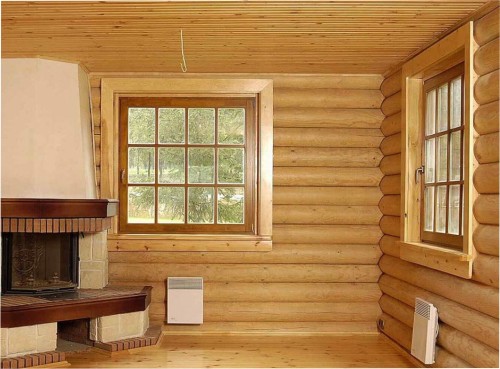

- Substances used for wood processing inside residential premises. Such formulations after processing the material form a thin micropoline on its surface, which does not give toxic substances to milder. This feature is very important for antiseptics used in residential buildings, since this way can be protected not only wooden structures, but also people who will be indoors. It should be noted that these substances are sufficiently stable and do not require annual re-applying on wood. Depending on the purpose of one or another room, you should select the appropriate antiseptic. For example, if you need to process wooden surfaces in places where large humidity and high temperature will always be present, choose a substance for baths and saunas. Do not forget to check the information from the accompanying documents. Manufacturers of high-quality antiseptics will necessarily provide all the necessary papers indicating the safety of their products for people and animals. Try not to buy the composition of unknown and unverified firms, giving preference to familiar brands. Perhaps in this case the price of such an antiseptic for wood will be somewhat higher, but it is better not to save on health.

- Antiseptics for external work are substances used to process wooden surfaces outdoors. Since the designs or surfaces in the open air will often be subject to adverse environmental impacts, such substances should be distinguished by reliability and high quality. Antiseptics for outdoor work often have a sharp unpleasant odor, which destroys only after the complete drying of the wood. As a rule, the disappearance of such a smell leaves 1 to 2 months. These antiseptics well transfer the impact of moisture and ultraviolet radiation, but it is categorically impossible to apply them indoors. In turn, substances for external work are divided into 2 types:

- impregnations are compositions that can penetrately penetrate into the wood structure and destroy mold, fungi and harmful insects;

- finish coatings exist in order to protect the impregnating layer of weathering. Such a composition cannot deeply penetrate the structure of the tree, but is capable of forming a impenetrable film on the surface of the material.

Impregnation and finishing formulations can be used individually, but you can also choose a combined drug that performs several functions at once.

Before you stop the choice on a particular antiseptic, do not forget to carefully examine information about the substance and read the instructions for use. The fact is that certain substances can cause corrosion of the metal, interact with sealants and adhesive compositions, simply be too toxic and poisoning the surrounding nature.

It is worth noting that any antiseptic tool for wood has some toxicity, so in the process of applying a substance, it is important to adhere to the safety and comply with the specified proportions.

What made antiseptics for wood

There are several substances that have the necessary properties that allow them to be used as antiseptic compositions for wooden surfaces:

- Sodium fluoride - powder substance used in construction to disinfect wood. The fluorine sodium is quite difficult dissolved in water, but this antiseptic penetrates well through wood fibers and is slightly leached. As a rule, 2-4% solution is used to process wood, which is applied to the surface of the material with a brush. Small details can be immersed in the substance completely.

- Another popular antiseptic is considered copper cune. It is easily divorced in water, the temperature of which is not lower than room. A solution with a substance concentration of 5-10% is used to disinfect wood.

- Instead of copper sulfate, an iron cunery is sometimes used. It is advisable to apply only in cases where wood is not in contact with the metal. The fact is that this substance contributes to the rapid formation of rust on metal elements. Both types of vaporams can change wood color, which sometimes aggravates the decorative properties of wooden structures.

- Oxidiphenyl is a phenol-based substance, which covers wood to prevent the development of mold and various fungi. The oxidiphenyl is dissolved in acetone or alcohol, the construction of a substance concentration from 2.5% to 5% is used in construction. Small wooden parts are immersed in the composition completely, on large areas, the substance is applied with a brush in 2 layers. Oxidiphenyl does not affect glue compositions, does not impair the strength of wood, has low toxicity for people, and also does not destroy. This substance does not change the combustible and hygroscopic properties of the material, does not cause corrosion of the metal.

- Zbarician bactericide is an organic substance based on mercury, its aqueous or alcoholic solutions is used for wood processing. Most often in construction it is an alcohol composition with a 0.2% concentration of substance. Details and surfaces are coated with 2 layers of bactericide. Among the advantages of this means, it is possible to name its high toxicity for bacteria and fungi, chemical permanence, the ability to penetrately penetrate wood fibers, relatively low cost. Zbar's antiseptic does not affect the properties of adhesive compositions and has a small corrosive effect on metals.

- Ethyl mercurphosphate - powdered organic substance based on mercury. This antiseptic is poisonous both for fungi and microorganisms and for humans. When applied to wood surfaces, it is necessary to carefully comply with all security measures.

Features of the use of antiseptics for wood

To process wooden surfaces has been effective and durable, it is necessary to consider some subtleties:

- Candle fresh wood with impregnation is best in spring or autumn. In the spring, when it begins, the wood is strongly exposed to the formation of mold and the growing of various fungi.

- If the material prepared was not processed in the spring, then in summer problems may arise in the form of wood aging. Wet under the rains, and then quickly hanging under hot solar rays, wood fibers dry out, the material is growing and cracking. Accordingly, such wood is noticeably losing in quality and durability.

- When processing materials by antiseptic compositions, it is important to adhere to the right technology, comply with the necessary proportions of the substances applied, as well as safety equipment. An important factor when working with wooden surfaces is their purity and dryness. Clean the processed parts can be used as using white spirit, and thanks to the ordinary metal scraper.

- Starting work, first of all, the most vulnerable zones should be processed: ends, transverse intersections, small parts.

- When working, the ambient temperature should also be taken into account. For organic solvents, this indicator is +5 ºС, for water-soluble substances, the temperature is +10 ºС. Air humidity in the process should be no lower than 80%.

Popular antiseptic compositions

- In the domestic market, the popular antiseptic for wood is "Sezhezh". It can be used in both the first processing of the material and for the coating of previously processed surfaces. Sezhenya is suitable for working with housing and public structures, perfectly copes with a variety of biodepers. This agent is not suitable for working with surfaces covered with oil compositions, varnishes or other hydrophobic substances.

- Pinotex offers its customers several types of wood processing. Among its products can be found both impregnation for soil processing and decorative staining compositions, as well as various quick-drying agents for the protection of the material. The colorless antiseptic "Pinotex" used on the outer surfaces is made mixed with the painting composition.

- On the domestic market you can also buy an antiseptic for Wood "Aquatex". It is an environmentally friendly product, so it is often used for internal work.

- Antiseptics "Tikkurila" are distinguished by reliability and resistance to various adverse natural factors. With the help of such a tool, it is possible to protect wood not only from moisture, the development of fungi and mold, but also from destructive ultraviolet radiation.

- "Pyrolax" is an antiseptic antipiren for wood, the purpose of which is to reduce the flammability of the material. In addition to protection against fire, Pyrolax is also able to extend the service life of the tree, reducing the intensity of its aging and warning cracking. Antiseptic for wood "Pyrolax" has a disinfecting effect on the material, killing mold, fungi, destroying tree beetles.