Concrete floors: sizes, weight, installation instructions Construction

Concrete floors are separate plates laid in a certain order. With their help, the floor for the upper tier of the multi-storey structure and the ceiling for the lower floor are formed.

The reinforced concrete panels continue to remain the most popular overlap due to its advantages:

- high strength and wear resistance;

- good sound and thermal insulation qualities;

- wide scope;

- relatively low cost;

- easy installation.

The disadvantages can be found in the weight of the products and the fact that the factory production of concrete floors, which correspond to the established standards, limit the possibilities of designers. It is possible to solve the problem with the production of plates for individual sizes.

Content

Classification of slabs of floors

Plate of overlaps classified:

- by type and amount of emptiness;

- in thickness;

- according to the method of support.

Made plates of overlapping from cellular concrete and from reinforced concrete. They also distinguish ribbed, beam and boiled plates. In addition, all of them are divided into the following groups.

- Full-tempered: reinforced monolithic products of increased strength. Used for the device for inter-storey floors of multi-storey buildings.

- Ribbed: monolithic products with rigidity ribs. Used as overlaps in industrial buildings.

- Empty: have round voids, which improves the heat and sound insulation properties of the overlap. This design has a smaller proportion.

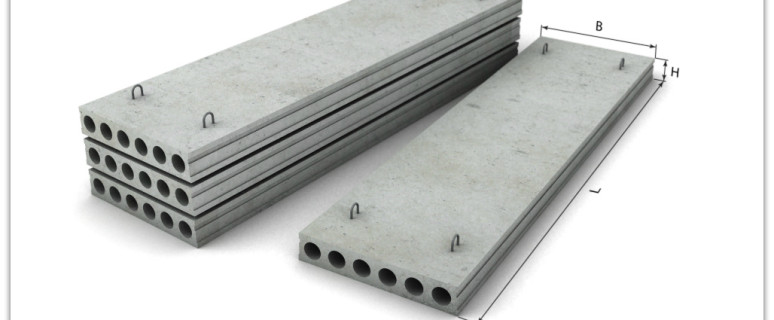

Types of overlap panels:

- 1PK, 1PT, 1PKK - hollow plates with a thickness of 220 mm with holes (voids) Ø159 mm, support - on two, three and four sides, respectively;

- 2PK, 2PT, 2PKKK - hollow plates with a thickness of 220 mm with holes Ø 140 mm, support - on two, three and four sides, respectively;

- 3PK, 3PT, 3PKK - hollow plates with a thickness of 220 mm with holes Ø 127 mm, support - on two, three and four sides, respectively;

- 4PCs are void, thickness - 260 mm (with voids of Ø 159 mm) for support on the 2nd sides;

- 5PCs are void, thickness - 260 mm (with voids Ø 180 mm) for supporting on 2 sides;

- 6PCs are void, thickness - 300 mm (with voids of Ø 203 mm) for support on 2nd sides;

- 7PCs are void, thickness - 160 mm (with voids of Ø 114 mm) for supporting on the 2nd sides;

- GHG - hollow (pear opening), thickness - 260 mm, support - on 2 sides;

- PB is full (continuous casting), a thickness of 220 mm, based on 2 sides.

The dimensional range of concrete slabs of overlaps manufactured by manufacturers in accordance with standards:

- length - from 1600 to 15000 mm;

- width - 0.6; 1.0; 1.5; 1.8 and 2.4 m;

- thickness - 160, 220, 260 and 300 mm.

The weight of concrete slabs, depending on the dimensions and execution, varies within 900 - 2500 kg.

Installation of concrete floors

Lifting plates on height is carried out using special equipment, for which the loops are provided. Installation is performed in accordance with the rules given in the technological map.

Phased description of the installation process.

- Check the integrity and compliance with the technical requirements of the support parts of the erected walls (they must be in the same plane), correct and clean the mortgage parts.

- A cement-sandy solution is applied over the reference surfaces with a thickness of no more than 20 mm.

- Laying the first panels are made from the end wall.

- The fixed panel is delivered from the stack to the place of installation using the lifting mechanism, after which its position is adjusted manually. During installation, the luminous devices are used (if necessary, with traverse) with a number of sling equal to the number of loops. Multiple plates are allowed if the crane load capacity allows.

- With the help of the level control the horizontal of the laid stoves: the drop of the upper surfaces of the adjacent panels should not exceed 20 mm, the lower - 4 mm.

- The laid panels are bonded with supporting walls and each other by welding the mortgage reinforcement at least in three corners.

- The seams between the laid stoves, columns and walls close up for the entire depth of cement-sandy solution.

- The empties from the outside walls are filled with light concrete to reduce heat loss.

Production of a monolithic plate on an individual project

In the event that the standard plate plate of the overlap is not suitable for its parameters for the device of the inter-storey overlap, it is necessary to manufacture a plate for individual sizes. There are certain advantages in this:

- the surface of the overlap is obtained seamless and durable;

- uniform load on the walls and the base of the building is ensured;

- there is an opportunity to freely fulfill the layout of rooms with many angles and bends;

- you can build a balcony slab without a painting plate.

The device of concrete floors requires compliance with the technological process and certain rules. First of all, it is necessary to calculate the concrete overlap, which is better to use the services of the project organization. It is important to accurately calculate the cross-section of the slab for the intended load. Experts will indicate which brand of concrete and what valves should be used.

Materials required for the manufacture of concrete slabs

It should be at your disposal:

- steel reinforcement Ø 10-12 mm;

- concrete m 350 or components for its production (sand, cement, crushed stone);

- plastic locks for fixing reinforcement;

- tool for bending reinforcement;

- materials for formwork (steel sheets, plywood or boards with bars).

After the walls are erected and leveled at the top edge, you can start a formwork device.

Installing formwork

In the event that it is not possible to use not finished removable formwork, it is necessary to make it. For this, cutting boards with a thickness of 25-40 mm or the sheets of moisture-resistant plywood 20 mm are suitable. In order for the solution to do not flow through the slots, the plastic film is laid on the bottom and the side. Collection of formwork is performed in stages.

- Vertical supports are installed, which are wooden bars or logs Ø 150 mm. The distance between the racks is not more than 1 m. Between the wall and the nearest racks should be at least 200 mm.

- Rigels are laid on top of the racks - a longitudinal bar or a channel for fixing formwork.

- The bricks are fixed, and then - plywood sheets. It is important that there are no gaps between the formwork and the walls.

- Supporting supports: Horizontal formwork must be at the same level with reference sites.

- The vertical formwork is mounted: the edges of the fence must be beyond the edge of the reference site at a distance of at least 150 mm.

- With the help of Waterpas, the horizontal of the formwork and the coincidence of its level with a horizontal surface of the walls is controlled.

IMPORTANT: To form a formwork after frozening concrete, machine oil is applied to metal sheets, and the wooden surface is covered with a thick polyethylene film (at least 50 microns).

Reinforcement of the slab overlap

At this stage, the following rules must be followed.

- The reinforcement frame must be collected from two grids, each of which consists of steel reinforcement Ø 10 - 12 mm. Cell size - in the range of 150-200 mm.

- The rods are binding in places of intersection of knitting wire Ø 1.5 mm. The longitudinal connection of the rods is allowed if it is necessary to increase the length. In this case, the nesting should be observed - 400 mm.

- The grid must be 150 mm to enter the edges of the supporting walls of the brick and 250 mm - on the walls of aerated concrete blocks.

- The position of the reinforcement grids: the lower must defend 20-25 mm from the horizontal formwork, and the upper one is at the same distance from the top surface of the plate. The grids are separated from each other by plastic locks, which are installed at the intersection of reinforcement rods.

- In the end of the frame, the end locks are installed to achieve greater stove strength in the wall of the wall. The grids are connected by special elements that are installed in a step of 400 mm for a uniform load distribution.

Important: The ratio of the length of the span to the plate thickness is 30: 1. For example, if between the walls distance is 6 m, it is necessary to make the slab overlap with a thickness of 200 mm. Accordingly, the distance between the upper and lower grid is about 125 mm. To fix nets, in this case, special supports with upper and lower shelf are fused from the reinforcement. They are installed in a checker in a step in 1 m.

Filling formwork concrete

The formwork is poured by concrete of factory manufacture. It is necessary to perform this in one reception so that the stove is monolithic. Technological openings should be provided for engineering communications, for which the internal elements of the formwork are established.

Freshlylated concrete seal a deep vibrator, which is necessary to remove air bubbles.

Concrete gains strength for 28 days. So that he does not crack, the first 10 days it should be periodically moistened or need to hide the plate with a plastic film. When concrete completely freezes, the formwork dismantle.

Basic Plate Styling Rules

- The span should not exceed 9 m. If the distance between the walls is more - columns are installed.

- The slabs are placed only on the bearing walls.

- The hatches and technological holes are recommended to cut on the junction of adjacent plates.

- The gap between the plates should be within 20-30 mm: this distance will provide the seismic resistance of the building.

- Laying plates dry is unacceptable: all gaps should be filled with cement mortar.

In conclusion, we propose to familiarize yourself with the video demonstrating the process of fill the concrete into the formwork of concrete overlap.