How to properly perform the heat insulation of the roof Insulation,Construction

In modern construction, much attention is paid to energy-saving technologies. The search for efficient materials and methods of thermal insulation of residential premises is constantly being conducted. This is due to the continuous growth of tariffs for heat and electricity and considerable costs of the content of housing, especially with a large area. In addition, the summer we have a short, heating season lasts 7-8 months. One of the important activities for the insulation of the house is the thermal insulation of the roof, since up to 30% heat loss falls on the roof. The use of the latest building materials allows the construction of high-quality and environmentally friendly roof thermal insulation.

Content

- What should be the right roof

- Device insulation roofing

- Roof thermal insulation materials

- Installation of thermal insulation roofing

- Thermal insulation of flat roofing

- Inversion roof

- Heat insulation for a scope roof

- Heat insulation by spraying polyurethane

- Heat insulation when repairing the roof

- Warm and cold heat insulation

- Heat insulation of soft roof

What should be the right roof

The roof is an important architectural and engineering part of the building. For the purpose of safety to the roof device, certain requirements are presented. All roofing materials and structural elements should be durable, stable and respond to fire safety standards.

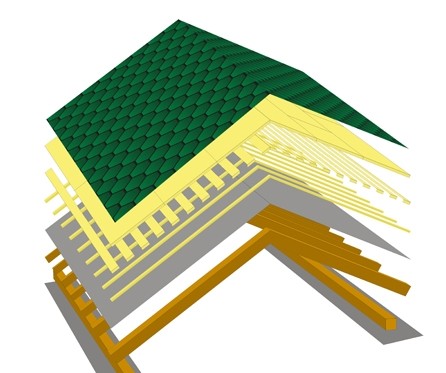

Roofing device:

- Interior decoration.

- Playproof layer.

- Internal finishing doom.

- Rafters.

- Bruks for ventilation gap.

- Roof lamp.

- Heat insulation layer.

- Super Diffusive hydraulic protection membrane.

- Roof coating.

To protect the building from meteorological precipitates, the top layer of the roof is the roofing coating, which provides a slope for the natural flow of water and the drainage system. From seasonal and daily air temperature drops protect the thermal insulation layer.

Roofing construction is subjected to a contrasting temperature effect: the inner surface of the roof has an air temperature of the room, and the outer is cooled in winter to -40c and is heated in summer to + 70-80 ° C. In addition, outside the roof is illuminated and uneven, the temperature of the individual parts of the roof differs by 20-30 ° C. Almost all building materials are exposed to stretching and compression under the action of temperature. To prevent the deformations and destruction of the roof, it is very important to choose materials for multi-layer roofing structures with an approximately equal coefficient of temperature expansion.

The change of thaws of frosts leads to the appearance of land and icicles, which delay water on the roof. Moisture penetrates the roof through the slot in tile or slate. To protect the building from leaks, a waterproofing layer is used.

The roof is subjected to the destructive action of moisture not only from the outside, but also from the side of the underproductive space. Water steam from the dwelling, lifting up, condensed on the inner surface of the roof. The more temperature difference in the house and on the street, the more intense the formation of condensate. Such a problem is particularly strongly manifested in winter when water flows, forming floors on the ceiling.

The moisture actually acts on the roofing structures, causes corrosion of metal elements and rotting wooden. An increase in humidity is only 5% reduces the thermal insulation function of the material by 2-3 times. For efficient protection of the roof directly under the heat insulation, a special steam-proof film is used. However, no vapor insulation material is capable of providing an absolute damage from moisture. To eliminate dampness, it requires the creation of good air circulation using ventilation gaps. For active ventilation, the installation is made of a special gap of 50-70 mm between the vapor barrier film and the roofing material. Many firms producing roofing equipment offer ready-made ventilation devices: Aerators for the skate and sweeps, ventilation grids and tiles, exhaust tubes.

The bias of the roof design depending on the roofing material and the climatic zone. In conditions of dry climate and strong winds, the angle of roofing slope is allowed to 30 °. With abundant sediments, the roof slope is 45 ° and more.

When designing the structural design, the stratum of snow is taken into account, which depends on the inclination of the roof. In the snow regions, the corner of the roofing is increased so that the snow does not accumulate on the roof. On the pitched roof there are snow designers for the prevention of avalanche-like snow and damage to the drainage system. The thermal insulation of the roof is also performed with the climate of the area.

When using a piece roofing material, the angle of the slope must exceed 22 °. When roofing the coating of roll materials, the optimal angle of the skate is from 5 to 25 °, from tiles and sheets of asbestos-cement - 25-35 ° and more. An increase in inclination increases the consumption of materials A, which means the total cost of the roof. The multilayer structure of the roof allows you to protect the building from unfavorable natural factors, significantly reduce heat loss and heating costs, create a comfortable microclimate in the residential premises.

Device insulation roofing

Planning the heat insulation device of the roof is carried out in parallel with the design of the building. The roof design takes into account, the material with high strength, vapor permeability, low thermal conductivity is selected. The thermal insulation must be fireproof, moisture and biolescent, durable. When repairing the roof is possible to replace the heat-insulating layer on the new insulation.

The heat insulation of the roof is made of several layers:

- Vapor insulation layer.

- Insulating layer.

- Ventilation gaps.

- Wind and moisture protection layer.

- Ventilation.

- Roofing.

Violation of the device of thermal insulation layers or incorrect installation leads to damage, and sometimes the complete destruction of the roof.

The fireproofing arrangement of the roof requires special care, since the remaining gap or the defect leads to the penetration of wet air. A permissible passage of moisture for vapor barrier is considered to be 22mg per 1 square meter per day. If the bandwidth of the booster layer is greater, steam will penetrate the insulation and condense. In turn, this will lead to the appearance of the Inea and Ice in winter and leaks of melt water in the spring.

Competently planned and mounted heat insulation of the roof will provide almost perfect protection at home. Roofing "Pie" from a vapor polypoletor, insulation, ventilation gap, wind and moisture protection layer prevents condensate and ensures the normal functioning of the roofing structure.

The thermal insulation system is suitable for all types of roofs, it does not require high costs, it has the simplicity of installation, practicality, durability. The insulation of the roof is simply necessary to create a healthy microclimate in the house and reduce costs for housing content.

Roof thermal insulation materials

For thermal insulation, the roof is used by special materials, allowing to increase the thermal coating resistance and reduce heat loss. The thermal insulation material according to quality standards should be biosticular, hydrophobic, non-toxic, fire-resistant, as well as have a long service life.

When choosing the heat insulator, the climatic features of the terrain take into account the climatic features. By chemical composition, organic and inorganic materials distinguish. Insulation are different form of release: soft, rigid tile and bulk. Soft thermal insulators include mineral wool, glass and coolant rolls based on paper or foil. Bulk insulation is produced in the form of balls and granules from wool, shale minerals, polyterol, plugs and are intended for floor insulation in attics and attic.

The main quality criteria for good thermal insulator are indicators of thermal conductivity and density. More dense and heavy materials increase the load on the supporting structures of the house, which is unsafe for some types of buildings. The thickness of the insulating layer is selected according to the requirements of SNiP, taking into account the energy flow of the building. The thickness of the thermal insulator depends on heat transfer resistance. It is calculated, based on the coefficient of thermal conductivity of a particular material. If the thickness of the rafted is insufficient for appropriate insulation, then a more efficient material with low thermal conductivity is used.

When using roofing insulation with properly calculated parameters, you can achieve the maximum heat saving effect. The lower the resistance, the less transport costs and the cost of installation. The homogeneity of the insulation and the convenience of laying, it affects the quality of stamping.

The modern market offers buyers a lot of varied in terms of technical characteristics of insulation. Mass demand now enjoy:

- Mineral wool is the most affordable thermal insulation material. It has sufficient density, excellent sound insulation, low thermal conductivity. All mineral wool insulation have a porous structure that allows you to skip steam. Mineral wool nonhygroscopic, does not burn, has a service life of up to 25 years.

- Cellulose insulation appeared on the market not so long ago, but already enjoy in great demand due to environmental friendliness, good air permeability, sound insulation, antisepticity and low thermal conductivity. The cellulosic thermal insulator does not allocate harmful volatile substances and does not cause allergic reactions. Cellulose insulation of non-combustibles, resistant to rotting, affecting mold and fungus and eating rodents. When laying a cellulose canvase, a solid coating without cracks and seams is formed.

- Polystyrene insulation: foamizol, expanded polystyrene and extruded polystyrene foam. The greatest practical application was obtained polystyrene foam. It has a minimum thermal conductivity, low weight and long service life. The polystyrene is not subject to the formation of mold, rot, fungus. A serious disadvantage is high flammability, complete destruction at a temperature of 90 degrees. Penosol is less common, characterized by low thermal conductivity, durability, low weight, waterproof, low cost. Penosol - economical and efficient thermal insulation material. The only minus coating is a sharp smell when applying and drying up the composition. The extruded expanded polystyrene does not lose its properties when the temperature drops from -50 to +75 degrees.

How to choose the right insulation

The effectiveness of the roof thermal insulation depends primarily on the quality of the insulation. When buying a material it is important to check the compliance of the insulation to environmental standards and building standards. Allocations of harmful substances dangerous to human health are unacceptable. The insulation must be designed specifically for roofing. It is desirable that the assembly work with the insulation is not difficult.

Attention should be paid to the service life of the heat-insulating coating, the proportion, thermal conductivity, characteristics of water-repellent, vapor insulation properties. It is better to choose thermal insulation material with foil coating.

Installation of thermal insulation roofing

With all the variety of structures of the roof of its insulation is made on similar principles based on the laws of physics.

Thermal insulation of the roof has a multilayer structure. "Roof pie" .sostoit of vapor barrier, insulation, the upper membrane with unilateral moisture permeability. Manufacturers of building materials producing "roofing pie" as a finished product. But it is possible to perform laying thermal insulation layers with their own hands.

First layer - liquid impermeable material to protect the insulator against the penetration of moisture from the room. Material deposited without gaps overlapped joints glued sealant. The upper vapor-permeable layer serves to isolate the insulation from moisture and release it to the outside.

Preparatory work

Before starting work on the roof insulation required to insulate the proper preparation of the surface:

- Check rafters to rot, fungus and mold. Necessarily result in the entire procedure of the roof structure - purified from dirt buildup, moss, parasites, get rid of moisture. With minor signs of lesions rafters purified sandpaper treated with antiseptic and stained with oil, a bitumen enamel or paint to insulate against harmful effects of the environment. If the damage is structural terms, they should be replaced.

- Check proper wiring. Damaged parts are repaired, replaced worn wires, switches prozvanivatsya, check all connections, joints, fasteners, joints. In the case of unfitness wiring it completely rework. For more precautionary check the wiring before installing the roof insulation must be supported by professionals. This will help to avoid further hazards to fire.

Methods of installation of the roof insulation

In building practice are two ways to apply thermal insulation to the roof installation:

- Internal insulation of the roof. It is the most common form of insulation, and practiced for flat and pitched roofs for. In the following order: first carried out interior decoration, then - vapor barrier, then - a heat-insulating layer, followed by - wind and waterproofing membrane and completing the construction of roofing material. When installing provide clearance for weathering moisture. Insulation must have the necessary parameters based on the load-bearing roof structure, and adaptation to the existing weather conditions.

- External insulation of the roof. Mounted on the basis of flat roofs with rigid plates, which are stacked on top of concrete slabs or pebbles. It is important when installing the thermal insulation of the external method to calculate the strength of the roof to protect the building and the people from the roof collapse.

Selection depends on the method of thermal insulation of the roof construction and the materials used. Installation of the thermal insulation of the roof covering, in principle, is simple, but still requires some technical training and the necessary tools. If there is no building experience, not worth the risk, it is better to consult a specialist. They get rid of unnecessary financial costs and perform the work at a professional level.

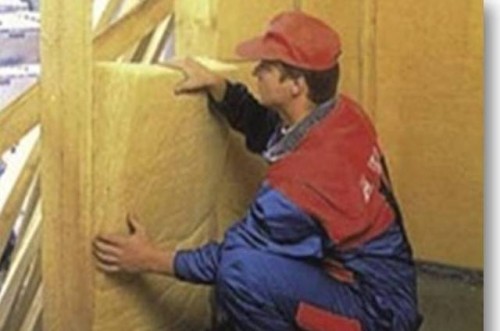

Installing roof insulation begins with laying paroizolyatora on the inside of the load-bearing structures. The most commonly used polyethylene and foil. The material is spread along a single web trusses and bars fastened to wooden structures with galvanized nails or staple gun.

When whole difficulty stacking material layer are 100mm in overlappings. Insulation is placed directly on a vapor retarding layer. Thermal insulation material cut to size. Insufficient thickness of the roof insulation may cause inefficient heat insulation structure, and passes at its laying will lead to the formation of "cold joints".

The waterproofing layer is attached directly horizontal to the rafters. Web material joined with an overlap width of at least 100mm. The film material is pulled tight enough slack height of not more than 20mm. Insulation between the film and form a ventilation gap. Counter-mounted on the film for subsequent lathing.

Properly configured device roof insulation not only reduces heat loss from buildings in winter, but also provides shade in the summer heat.

Roof "pie" is a reliable barrier against moisture and preserves the integrity of the truss for a long time. Thermal insulation of the roof is done for many years, so during installation should not skimp on building materials and quality of work. Remodel is always more difficult and more expensive, and the cost of insulation heat quickly compensated by savings in heating the room.

Insulation of flat roofs

Most residential multi-storey houses have flat roofs. Flat roofs are also erected in the construction of industrial facilities, public buildings, industrial premises, trade and logistics centers. Standard flat roof consists:

- The base (reinforced concrete overlap or professional flooring).

- Vapor insulation layer (polymer films, bitumen and polymeric materials).

- Insulation (foam).

- Waterproofing coating (bitumen and polymeric materials).

For insulation, the roof is used outdoor and internal way. Also distinguish between the same and two-layer thermal insulation systems. In a two-layer system, the lower layer is actually insulating, the top layer serves to redistribute mechanical load. Due to this, a decrease in the weight of the roof and load on the overlapping is achieved.

For the repair of old roofs, mainly a single-layer thermal insulation system from the insulation of one density is applied. The disadvantage of the standard flat roof is the frequent disruption of the waterproofing layer under the action of external factors.

For the arrangement of the outer insulation of a flat roof, rigid heat insulating plates are used, which cover the base on the bars of the supporting structure. Insulation materials are pressed by pebbles.

For the insulation of a flat roof from the inside, polystyrene foam plates with a thickness of 25mm are used. Bulk materials for insulation overlap is placed between bars and level special strap. For insulation of the attic floors, the mineral wool is suitable, which is placed on overlapping or between the rafted bars.

Each of the heat-insulating materials is inherent in certain properties that are the selection criterion for flat roofs of different types. The foam is used for thermal insulation of non-exploitable roofs and only if there is a refractory cushion as part of the roofing pie. She can serve on the insulation and at the bottom of it - reinforced concrete overlap. The extruded thermal insulator is used to cover the inversion and loaded roof. On lightweight structures and non-exploitable flat roofs with screeds, as a rule, a rigid mineral wool insulation is used.

Inversion roof

Inversion method of insulation of flat roofs is quite common recently. The insulation is placed on the waterproofing layer, which increases the heat-physical properties of the roof. The waterproofing layer is protected from sudden temperature drops, direct exposure to meteorological precipitation, mechanical damage. As a result, waterproofing is improved, and the heat insulation of the roof.

Inversion roof has the following device:

- Base overlap.

- Waterproofing.

- Heater (extruded polystyrene foam).

- Safety layer (filter synthetic layer).

- Primary gravel layer.

The safety layer delays precipitation, the extruded penity is reliably protects the underlying waterproofing layer and the base of the roof from moisture and temperature surges.

Inversion roofs make it possible to use open areas for various purposes (operated inverted roofs). In large cities on flat roofs, green terraces are arranged, summer cafes and even parking lots.

In the device of thermal insulation of flat roofs, extruded insulation, mineral wool, foams are usually used. Insulation material should have water resistance, strength, fire safety.

Heat insulation for a scope roof

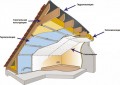

The scanty is called roofs with an angle of the slope of more than 10 °. The technological features of the installation of thermal insulation of flat and pitched roofs differ significantly. Scope roofs are arranged more difficult and more often used in individual housing construction. The frame carrier system of the pitched roof consists of rafters, skate, crates. Bearing elements are made of wood or metal. The rafters are located around the perimeter of the roof at a distance of 60-100 cm apart.

For thermal insulation when installing or repairing the roofing, the insulation is placed inside the frame in the gaps between the rafters. The heat insulator is placed in one or more layers depending on the necessary coefficient of thermal conductivity and operational conditions. In any case, the thickness of the heat insulator for the pitched roof should be at least 10 cm. At low rafters from the inside, an additional framework is stuffed, to which thermal insulation are placed. The insulation fastened between the rafters is closed from the inside with a vapor barrier layer from the accumulation of moisture and the formation of condensate. Ready thermal insulation, depending on the functional purpose of the undergraduate room, is covered with plasterboard or other facing material. Traditionally, mineral wool or glass plates are used for the insulation of the pitched roof.

The outer side of the insulation is covered by hydro and windproof layer. For these purposes, there are diffusion, superdiffusion, anti-condensate membranes. They are fixed directly to the rafters. Between the insulation and the membrane, the gap is left. Before mounting the roots to the rafters, the rails are nourished with a thickness of 5 cm to create an air gap between roofing and membrane. For the pitched roof, the insulation is chosen with high vapor permeability. Mineral wool insulation and staple glasswater freely skip water vapor. Glasswater is more hygroscopic, therefore steam and waterproofing are performed with special care. The vapor-permeable, "breathable" insulation helps to preserve the integrity of the supporting structure and to increase the duration of operation of the roof.

The selection of thermal insulation for the pitched roof is made depending on the characteristics of the building. In the finished exploited building, the main or additional thermal insulation is carried out from the inside of the roof along the rafter structures.

The unfinished building where the roof covering is not yet installed, rational spending insulation on the outside of roof structures.

In the non-residential attraction, the floor is insulated with a ceiling for rooms. In the case of equipment, the attic under housing is installed thermal insulation throughout the carcass contour. Materials for thermal insulation of pitched roofs should have a high thermal and sound insulating properties and light weight.

Features of thermal insulation of black and attic roofs

There are differences in the thermal insulation of attic and attic space, which is due to the fundamental difference between these device types of pitched roofs.

The mansard roof is insulated along the Skate itself, and in the attic room - the insulation is placed between the lags on top of the ceiling floors.

If it is planned to use a attic, like a utility non-residential room, the thermal insulation layer is closed with wooden boards to protect against mechanical damage when walking. In the event of rare visits to the attic, instead of the flooring, you can restrict ourselves to the pedestrian traps.

The living room in the attic, attic, requires considerable effort to arrange, but it expands the useful area of \u200b\u200bthe house. In the equipment of the attic, primarily organize a system of underpox ventilation and thermal insulation. The thermal insulation of the attic roof requires a larger consumption of the insulation and boards compared to the attic roof. Installation of vaporizolation and waterproofing is performed in order to protect the insulation from penetrating steam and condensate, which is formed on the inside of the roofing coating.

For thermal insulation of the pitched roof, insulation of a certain type with the corresponding physicochetics parameters are selected: small and medium hardness and density from 35 to 125kg per cubic meter.

The insulation of the pitched roofs perform materials with mineral and fiberglass base. Heat tips are cheaper, but better heat. Mineral wool insulation less environmentally friendly.

With the insulation of the attic of the attic of the roofs of rigid materials. The thickness of the rafter is measured and heat-insulating plates are prepared. The width of the slabs should exceed the interval between the rafters per 1 cm, and the thickness of 2.5 cm is less than the rafter feet. Plates are fixed using nails, screws, mastic or glue.

The heat-insulating materials for the roof should be highly resistant to compression and separation of layers and other mechanical effects to reliably resist the wind and the load of the snow cover.

Heat insulation by spraying polyurethane

It is used to insulate any surfaces of all types of roofs. Fast, convenient and economical way. It does not require dismantling the old roof, so it can be used to repair the roof. Especially effective in complex areas of the roof with a multitude of different elements: masts, ventilation pipes, joints, chimneys. As a result of spraying, a light durable thermal insulation layer is obtained that does not create a load on the roof. Polyurethanes by thermal insulation properties are superior to extruded polystyrene foam and mineral wool.

Heat insulation when repairing the roof

During roofing and repair work, the roofing coating has become dissenting and seal various design elements.

Repair works of the roof consist of two stages. First, the heat-insulator is styled in the form of a screed, then the installation of roofing materials is performed. Rolled materials can be arranged after the final drying of the screed. To accelerate the grasp of concrete, special additives are used, which reduce water consumption and increase the stability of concrete to damage.

Polystyrevbeton, foam concrete, ceramzite concrete are used for styling. The use of these materials reduces the deadlines for repair work. The production of concrete mix is \u200b\u200bperformed near the construction site. To obtain a homogeneous mixture of good quality, a special technique or a pneumatic phase mixer is used. Before laying, the heat insulator is aligned and compacted by vibrating and thrombing. For light concrete fillers, only vibrations apply. The repair of the roof is completed by the processing of the entire roofing surface by the protective polymer composition.

Warm and cold heat insulation

The warmth includes roofs with a attic. The thermal insulation of such a design is provided by an additional airspace between the roof, walls and overlapping of the upper floor. In this case, the additional thermal insulation of the roof may not be required. The attic design effectively protects the building from the cold, provides constant ventilation and moisture exchange. In the underfloor room you can equip the attic under the residential room in which the walls are roofing. For good thermal insulation, the roof is height from the floor to the crown of the attic room should be at least 1.5m.

It includes roofs without a attic, which are erected most often over unheated premises, garages, economic buildings. Such a roof is intended only for precipitation. The thermal insulation of the roof in this case is not required.

Heat insulation of soft roof

A flexible tile is used as a material for making a soft roof. This material has a long history, and its popularity in our time is gaining momentum. The undisputed advantages of a soft roof is low cost, economical consumption of material during installation, excellent noise insulation, tightness, resistance to rotting and corrosion. The life of a soft roof for over 50 years.

Mineral wool, foam, polystyrene foam and polyurethane foam are used to heat insulation. Polyurethan is the most promising insulation due to absolute waterproof and ease.

There are two main schemes of warm-blood warm roof: single-layer thermal insulation and two-layer:

- Single-layer system is economical, but ineffective. Its use is justified in old or repaired buildings. According to this scheme, thermal insulation is performed from the materials of the same density.

- The two-layer thermal insulation scheme is standard for new buildings. The bottom layer, the main, consists of a heat-resistant material with a thickness of 7-17 cm. The two-layer thermal insulation system prevents heat leakage and does not have a special load on roofing structures.

"Roofing Pie" for a soft roof from bituminous tiles

Warm option:

- Bituminous tile.

- Lining carpet.

- OSB or plywood.

- Waterproof film.

- Insulation.

- Variazolation film.

- Rafters.

The thermal insulator is attached to the soft roof of the dowels. It is necessary for such a roof of the ventilation channel to ventilate the undercase.

For a comfortable stay in the winter time, the insulation thickness should be equal to at least 225mm. Thermal insulation of the soft roof includes vapor and waterproofing films that prevent water and steam into insulating material. To increase the service life, it is recommended to install a flat stable base from a t-shutter board or OSB plywood under a soft roof. A special lining carpet is fixed throughout the roof area.

Cold Option:

- Bituminous tile.

- Lining carpet.

- OSB or plywood.

- Dooming step.

- Rafters.

It is used when building canopies, garages, household buildings that do not require insulation.

When arranging the heat insulation of the roof is required to strict adherence to all engineering and technical rules, otherwise homeowners can expect trouble in the form of leaks or dampness. Disorders or deviations in the layering technology of thermal insulation layers may result in serious damage to the roof. Being protection for the house, the roof and itself needs to be care. Packed by the latest technology roof reliably protect the house from the destructive effect of adverse climatic factors: cold and heat, precipitation, wind and dust.

New comments

Add a comment

To send a comment you need authorize.

Repair the roof or the roof itself is quite complicated, so we turned to the root, which we also did the thermal insulation, a very good company, no problems when working with them did not arise.