How to make ventilation in a private house: Tips and recommendations Climate

In most cases, modern building and finishing materials provide for the creation of a hermetic structure. This fact requires a special approach to the device of a high-quality ventilation system. Especially relevant for rooms with high humidity. On how to make ventilation of a private house, and it will be discussed in our article.

Content

Ventilation requirements in a private house

Of course, the best option will be the design of ventilation at the construction stage. But this fact is not the main requirement for the system.

About efficient ventilation in a private house testifies to the receipt of fresh air in the amount of 2.5-3.5 m³ / hour. The system itself should be:

- silent;

- economical;

- uninterrupted.

Regardless of the ventilation scheme of a private house, you need to take care of high-quality air flow. The flow pursues one goal - the movement of air flows must end in the polluted room (in the bathroom or kitchen).

In this room, exhaust equipment is installed, to which the exhaust air enters through the overleum grilles in the doorway. Air flow can be carried out and by creating a gap (2.5 cm will be sufficient) between the lower part of the doors and the floor.

Special attention is paid to the right choice and styling of private house ventilation. Their minimum cross-section is 15 * 15 cm. Pipes must:

- to withstand wind load at guns up to 30 m / s (installation of too thin pipe is unacceptable because it breaks);

- have a small weight;

- be resistant to corrosion;

- excess the level of the skate in such a way that airflow is created, and not a reverse thrust.

The best option for ventilation is the use of plastic pipes that differ in a smooth surface and excellent antistatic characteristics. The possibility of fitting PVC pipes facilitates the installation process. The only thing to be envisaged when laying pipes is to create a minimum amount of turns and branches. Each branch reduces the efficiency of the private house ventilation system by 8-10%.

Types of ventilation systems

There are two types of ventilation:

- natural;

- mechanical.

In turn, the mechanical ventilation system is divided into:

- inlet;

- exhaust;

- supply-exhaust;

- with heat recovery.

The choice of a particular ventilation system depends on the features of the air exchange room. After all, the comfortable stay in the room depends not only for the presence of fresh air (or its temperature), but also on the speed of movement of flows (it must be minimal).

Naturally, the index of the air exchange of natural ventilation (about 1 m³ / hour) is significantly lower than the mechanical ventilation indicator (from 3 to 5 m³ / h). The presence of an effective natural air exchange will create the most optimal conditions for staying in the premises of people.

This does not apply to the cases when without a forced air, you can not do without:

- the maximum possible diameter of the channel is necessary at a low speed of movement of air flow;

- if it is impossible to create a channel with a large cross section.

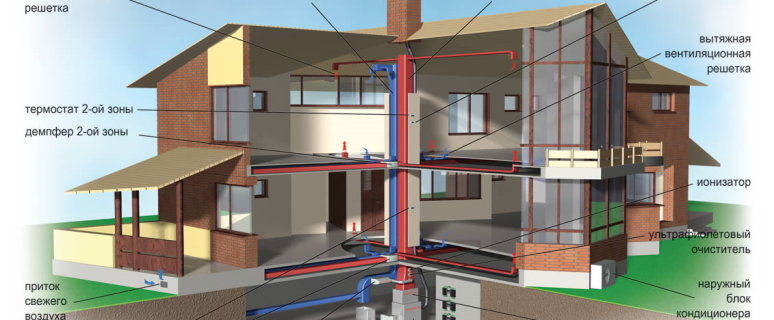

The process of the private home ventilation device itself consists of two main actions:

- determination of the location of the ventilation elements (equipment, air ducts, exhaust air extracts and fresh air supplies);

- acquisition and installation of air ducts and equipment.

Air ducts are 3 species:

- round;

- rectangular;

- flexible.

Round and rectangular products have a smooth surface. But unlike rectangular round air ducts are characterized by minimal resistance to air flow.

Flexible material due to an uneven corrugated coating is characterized by the greatest resistance. But without flexible air ducts, do not do in places where the channel has several branches (for example, in the case of connecting the kitchen extract to the trunk channel).

Natural ventilation device in a private house

Normal air ventilation is achieved due to a good fifth of fresh air from the street with the right movement along the ventilation channel.

Natural ventilation in a private house is carried out by:

- opening of the vents, windows or doors;

- use of supply valves.

Windows, windows and doors

This option involves the ventilation of the room using:

- Open window for venting (plastic window). It is fraught with the maximum thermal loss and the occurrence of condensate on the slopes and the window block in the winter. Air exchange occurs within 40-70 minutes.

- Fully open windows. Designs are not cooled overly. To ventilate the room is enough 6-10 minutes.

- Open windows and entrance doors. From the ventilated rooms will have to go out because there is a draft. Venting rooms occurs within 3-4 minutes.

All these ways of ventilation of the private house are necessarily used if the walls are separated by airproof thermal insulation material and windows from metalplastic are installed. If for some reason, ventilation by opening the windows, windows and doors is not an acceptable option (small child, sick family members), then you should use the supply valves.

Supply valves

The main characteristic of metal-plastic windows is tightness. After sealing the slots between the windows and the wall of the mounting foam and the slopes with cement mortar, the air will not penetrate the natural way into the house. To solve the problem of air ventilation, resort to the installation of the supply valves.

If windows are only mounted, you can make an order of blocks with supply window valves. They are a built-in hole with which the supply of fresh air is adjusted.

With the installed windows, you will have to use the intake wall valves that are round nozzles. The nozzles are inserted into the wall and close with lattices on both sides. Adjusting air intake is carried out using an internal valve grid.

Bedroom, Hall and Dining Room - Best spaces for mounting supply valves. This is due to the fact that the correctness of the movement of air flows should be observed (from residential rooms in the bathroom, toilet or kitchen).

Valves are placed near the windows. Preferably behind heating radiators. In this case, fresh air will enter the room already heated.

Carrying mechanical path

Exhaust ventilation

The exhaust view of the air exchange room involves using the exhaust fan, which is installed in the channel (usually attached to the wall). Installation of fans occurs in the most "dirty" rooms: bathroom and kitchen.

Assortment of exhaust fans is diverse:

- With humidity sensor (for bathroom). Function until the establishment of normal humidity.

- Attached to the electrical switch. Turning on the drawing occurs with a delay of a few seconds after turning on / off light.

- With noise-absorbing bushings made of rubber or metal.

To select a specific model for an exhaust ventilation device of a private house, the expense of extractor and pressure loss is calculated when the air moves through the channel. These indicators are determined based on the length and material of the manufacturer of the air duct.

The power of the fan has a direct impact on the amount of remote exhaust air. Moreover, the effective work of exhaust ventilation directly depends on the high-quality tributary of cold air from the street. In fact, the feeding of the hood serves as a supplement to the natural air exchange.

When laying air ducts, you can use this scheme:

- the main elements are made as hard as possible from the galvanized sheet;

- for the branch device, corrugated material is used;

- to prevent the occurrence of condensate, insulation of air ducts from ventilation equipment to an exhaust grille is performed.

Forced ventilation

The principle of operation of the supply ventilation of the private house is similar to the work of exhaust equipment. The only difference lies in the fact that the fan of fresh air is injected. Removal of exhaust air occurs with the help of channels intended for the natural air exchange.

The fan that supplies the room with fresh air, can be equipped with a heating element. The performance of the ventilation system depends on the diameter of the channel. Lack of supply ventilation - big heat loss in winter.

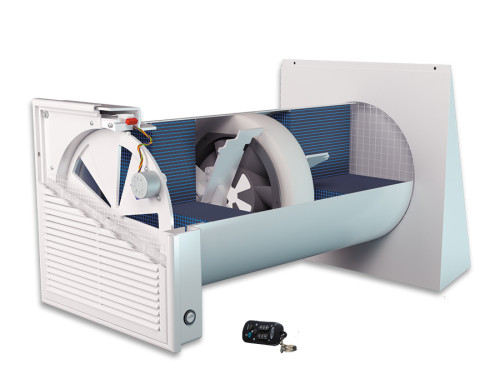

Supply-exhaust ventilation

Based on the name, it is not difficult to guess that the work of this type of air exchange is based on the use of various fans. The simplest ventilation system provides:

- fresh air supply by injection fans;

- removal of exhaust air with exhaust equipment.

In winter, air flows coming from the street can heal. Thanks to the supply and exhaust ventilation, efficient ventilation of the rooms is achieved. The only "minus" of such an air exchange is a large cash spending on its maintenance.

For this reason, in our days, the demand for supply and exhaust systems with heat recovery increased, which allow you to save on heating.

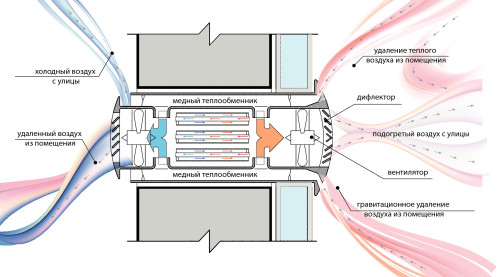

Ventilation with recovery of thermal energy

In winter, there is too much heat for heating fresh air coming from the street. To prevent this, recuperators are used for the device of the ventilation system. Thanks to their installation, heat savings are at 50%.

Air recovery can occur at different times of the year:

- upon the occurrence of a strong frost, the heat recuperator brings the temperature in the room to + 20ºС using the built-in heating element;

- on hot days, on the contrary, the incoming air is cooling (the cool exhaust air passes through the recuperator and cools the incoming flows).

Performance of the ventilation system depends on the coefficient of recovery. This indicator indicates the amount of thermal energy spent for heating fresh air coming from the street. It is better to use rotary recuperators with a coefficient of 75-85%.

When acquiring equipment, it should be noted that some manufacturers indicate the recovery coefficient of 98-99%. This indicator obtained according to the results of laboratory studies. In practice, the minimum coefficient of recovery of high-quality equipment will be 85%.

As for the place of installation of the recovery, it is better to determine it in advance. Usually, the equipment or attic is chosen to accommodate the equipment. When installing the recovery in the attic, the equipment should be covered with heat insulating material. Otherwise, the coolant will freeze, and the recuperator fails.

Features of the creation of ventilation indoors with gas

Carrying the room where the gas boiler is installed is a prerequisite. Gas combustion products are harmful to the human body and lead to the development of severe diseases. In addition, they are also explosive.

Gas ventilation in a private house can be any of the above (both natural and mechanical). Everything comes down to compliance with the following norms:

- Absolute tightness of the ventilation system. Seams where the elements of the chimney are connected, close to heat-resistant sealant. Air ducts are covered with thermal insulation material.

- To one air duct you can connect a maximum of 2 units of gas equipment. Even if the equipment is at a decent distance from each other.

- The ventilation canal should only go outside.

- The selection of fans is carried out on the basis of the power of the gas boiler. To maintain the process of burning, oxygen is sufficient. Otherwise, the boiler will be covered with soak, and its performance will significantly decrease. The drop in the oxygen level is fraught with the occurrence of reverse thrust.

- Laying air ducts for the gas column is carried out in a strictly vertical position. The length of the chimney must exceed 4 m, and its upper part should perform above the roof at the level of 1 m. Air ducts are recommended to insulate.

- The use of gas stove in the kitchen is recommended when the ceiling height is more than 2.2 m. The ventilation channel should be located at the top of the room.

Creating a ventilation system from "zero" involves the implementation of such actions:

- placed the location of the hole for the air duct;

- the perforator makes holes in the middle and around the circle;

- with the help of the hammer and chisel, the wall covering from the middle;

- a duct is inserted;

- sealant close the slots between the wall and the air duct;

- fanned fan;

- mounted ventilation grille.

The chimney device for the gas column consists of such steps:

- fastening the passage nozzle to the wall;

- connection of the nozzle with a rotary element at an angle of 90º (the column will be attached from the inside);

- installation of nozzles from the bottom up (clamps are used for their compound);

- uniform distribution of fasteners throughout the pipe (sufficient distance of 2 m), followed by fixing them to the wall;

- checking the performance of the system (about efficient ventilation indicates the slope of the flame of the burning match towards the pipe).

Video about ventilation device in a private house: