How to make vibrostol for paving slabs with their own hands Useful advice

How cool to have a private house or a cottage with well-kept lawns, smooth paths and a swimming pool, where you can relax and relax, extinguishing from the everyday bustle. If you can not afford a large amount of money from the budget, but at the same time you want the paths of your country house to decorate the paving slabs, the vibrotol for its production, made by their own hands is what you need.

Content

What is the vibrationtol?

Vibrostol is a simple design that will be required to you for self-making tiles for country tracks. Through this device, the tiles of various forms produce, and the material is the concrete mixture.

Such a device is quite possible to make it yourself. A homemade vibrotole for paving slabs is an upper plate attached to a metal base with a moving compound, and the engine leading it in motion. When the plate vibrates out thereon forms are, filled concrete, the air bubbles are located and voids disappear. This provides adequate quality and strength of ready products.

In order for your vibrotol, manually, the perfectly functioned, the countertop must have an absolutely smooth surface, and the engine is uniform vibration. If you do not take care of this by choosing a material for a self-made device, then the manufactured tiles may be uneven, and difficulties will occur when they are styling.

Material and tool that will need to work

To carry out the intended, you will need:

- metal tube - 4 pcs.;

- chamber profile or corner 50x50;

- metal sheet for table top;

- engine required power;

- springs made of steel that will provide vibration;

- apparatus for welding;

- bolts that will be recorded by the engine - 4 pcs.;

- drill;

- bulgarian.

Sequence of independent manufacture of vibrationtol

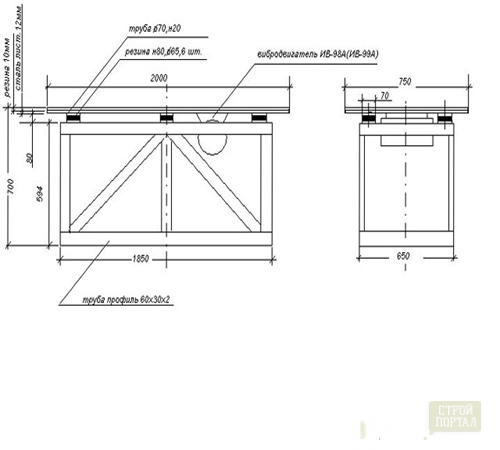

Vibrotole for sidewalk tiles, the drawing of which is shown below, is not too complex design. Make it easily when complying with a certain sequence of actions:

- the base on which the countertop will be attached is made from a channel or corner. The dimensions of the vibrationtol for paving slabs can be different, depending on your desire, but the standard is considered to be size 700x700. Reflecting on the dimensions, it should be remembered that they must correspond to the power of the selected engine;

- four metal pipes will be legs. To the base they are welded by the welding machine. To ensure the device maximum stability should be welded to the legs of metal plates and fix them with concrete. If this is not done, it will be possible to move the table from place to place, but it will depend on the quality of the surface. If it is fixed inpatient, it will be possible to use it only where it is installed, but stability is provided by 100%;

- the height of the table is selected individually, the main thing is the convenience of the Master and the location of the engine at a distance from the ground;

- the tabletop must have a perfectly smooth surface, as shown in the vibrostol diagram for paving slabs. If this is not taken care and placed on the work plate, which is tilted, then the mixture is simply perceived through the edge;

- in each corner of the design and in the center weld steel springs in the amount of six pieces. Perfect springs from mopeds, converted two;

- from above on the springs, we put a metal sheet with a thickness of 8 mm, and the engine is dripping to it. It is better to have it, relying on the drawing data;

- on the surface of the metal sheet lay the shape for the pouring of the concrete solution. It is either purchased in specialized points of sale, or made independently. If low-size tiles are required, then several pieces fit them on the table.

Following this instruction, any homemade sample can produce high quality tiles for your own needs, while decently saved the means. Self-made vibrotole can produce up to 60 square meters of tiles per day.

How to choose a suitable engine for vibrationtol

This is perhaps the most difficult stage in the process of making the device. It is quite acceptable for these purposes the engine from the washing machine. It works very well, but has a significant drawback - a short time.

It can withstand about 20 or 30 working cycles and then gets up. He begins to hang out the axis and / or encourage the bearing. The engine is not able to hold out the engine from the washing machine for a long time in the conditions of elevated loads offered by vibrostol.

Very good for this purpose, the Vibrator IV-99 E 220 Volt. Its value is approximately 6,000 rubles, but it copes very well with the work. How to prepare an engine for installation is usually indicated in the instructions and should not cause difficulties.

In addition, it will not be superfluous to set the AC potentiometer to adjust the vibration force. By changing the voltage level, you can adjust the oscillation frequency individually for each type of solution used. Although, if you wish to save or aslender, you can do without such equipment.

Nuances in the manufacture of vibrostol

- the design workstop must have a certain mass. It is calculated depending on the size of a particular table and materials used for its manufacture;

- the choice of material for the work plate should be approached responsibly. It should be not only durable, but also resistant to vibration, dynamic and static load;

- it is also necessary to calculate the amplitude of vibrations. From them will depend on the quality and aesthetics of the appearance of products produced. If this parameter does not take into account, then the technological process will violate that it will inevitably affect the final result;

- the engine must be fixed in a certain place, according to the drawing. The table will not be able to function high quality and in full power if the engine operation is broken.

For those who want to make a vibrotole for paving slabs, the video located below will serve as a visual illustration.

New comments

Add a comment

To send a comment you need authorize.

Thanks for the idea! Cool! And what motor motor? Instead of pillows, you can put springs?