How to insulate the floor in the bath Baths, saunas and pools

The adoption of bath procedures will be pleasant and useful if the stable temperature is maintained inside the bath for a long time, sufficiently high so that you can easily go high.

Content

One of the main tasks of builders is building construction with the correct thermal insulation of each element of the structure. According to the laws of physics, a larger amount of heat loses the construction through the roof and walls, but the floor in the bath should be insulated - not only for heat, but also to create in the steam room and the rest room is really a comfortable setting.

Is it necessary to insulate the floors?

The floor in the bath, due to the purpose of this room, is constantly under the influence of negative factors:

- high humidity, because water hits it constantly;

- high temperatures that are supported in the steam room.

The effects of water and the pair negatively affects the strength of the materials, of which the floor is manufactured, and also contributes to the development of fungi and mold, pathogens. It is not difficult to guess that such a situation can have an adverse effect on people who come to bathe in a bath.

The view is that if the floor in the bath becomes warm, then the microorganisms will grow even more active, does not have sufficient grounds - with the right selection of materials and their high-quality installation, such phenomena will not be observed.

Not insulated floors will constantly cause a sense of discomfort from visitors:

- the air temperature near the floor will be much lower than at an altitude of 1-1.5 m;

- steps with barefoot legs on the cold floor at high temperature indoors are unlikely to cause pleasant sensations. It has the meaning and inertia of materials from which the purple floor is made.

Choose high-quality material

Materials for floor insulation in the bath is recommended to choose carefully - after all, this room with high humidity, and porous or mineral insulation will not suit it. The optimal option is the use of materials with a closed cellular structure, such as foam plastic, which will cope with the task of insulation.

It is not recommended to use for shelter floors in pair linoleum - high temperature will provoke the selection from its surface harmful substances.

Features of the installation of thermal insulation and the principles of its arrangement depend on the material from which the floors are made.

How to make a warm wooden floor in the bath

Thinking the work on the insulation of the floor is preferably at the design stage of the room. If the thermal insulation is installed during the repair work, it will take dismantling the walls of the walls.

Most often, extruded polystyrene was used as insulation - the material is environmentally friendly, which has sufficient rigidity, characterized by ease, which does not require the strengthening of the foundation, economical.

Important: Installation of foam can only be performed on the perfectly aligned surface.

Due to its ability, not to absorb water, expanded foam does not lose thermal insulation qualities during operation, its thermal conductivity remains quite low for a long time. The material is not inclined to decompose when in contact with water or soil, its use does not lead to negative consequences in terms of environmental pollution.

To obtain a good result, it is enough to lay a layer of polystyrene foam 90 - 160 mm thick. To minimize heat loss, the layer can be increased to 250 mm.

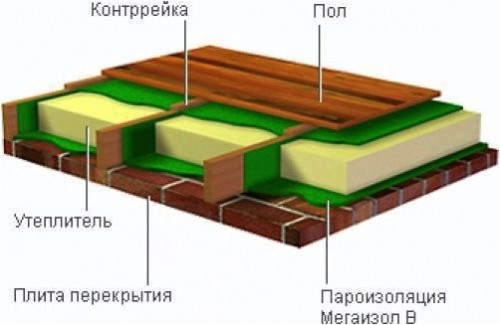

To make a warm wooden floor in the bath takes:

- Lay the foundation and build the walls.

- Install overlapping beams that will serve as a base for the floor.

- Wash the draft floor from the cranial bar.

- To lay a layer of vapor barrier - rubberoid or pergamine.

- Machine the insulation layer.

- Perform waterproofing.

- Welcome chalks of the first floor.

For the manufacture of floor in a bathroom, you should take boards from coniferous rocks: pine, fir larchs. It is not recommended to give preference to a poplar board, aspen, linden or oak.

To prevent the floor rotting, it will take careful processing of all elements of a wooden design with modern antiseptics. But it is not particularly fascinated by them in the steam room - the evaporation arising at high temperatures may adversely affect the human body.

In the steam room, it is better to use well-dried boards, their laying can be performed without cracks. Mixed boards are not fixed, drying the baths, and only after that thoroughly fasten the boards - this will allow minimizing the number of slots and their size.

Sometimes in the steam room make the removable floor - the board are not nourished, if necessary, they are removed and dried, laying on the time of drying spare. Of course, this option will require effort and time. A more efficient option is to use modern aggregates for drying floors.

Warm bath - Concrete floor device

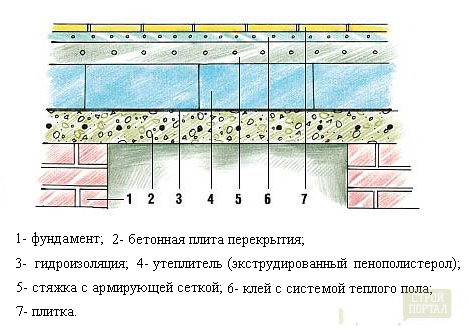

The device of insulated concrete floor is carried out in several other principles:

- The foundation lays a concrete slab base.

- It is covered with waterproofing from above, most often - coating, for example, bitumen-rubber mastic, in several layers.

- Next lace a layer of hydrokhotlocola.

- The following layer is mounted by a layer of insulation - extruded foam, it is possible to use clamzite as a heat insulator.

- The insulation is poured with a layer of cement-sand mortar and make a screed, its thickness is at least 30 mm, while the reinforcing grid is used.

- After the screed is aligned, a layer of tiles can be laid on it.

If desired, a warm floor can be installed between the screed and tile.

To prevent possible injuries from drops on a slippery tile, on top of it, fastened from the traffic jams go boards. With the help of supports, the flooring is lifted over the floor level - this will contribute to the active drying of the surface. With a large square of the steam, the flooring makes from several sections.

In construction, perlite is often used as a heater - the material is light, requiring care when working.

- To improve the insulation layer, a solution is made (in proportion 2: 1) from perlite and water, cement is added to it, mix well. Then add more perlite bucket, stirring brought the solution to a plastic state.

- The mass of the thin layer is applied to the surface of concrete, dried over the past week. Next, the surface is poured with a layer of concrete.

Do not forget that the floor bath device should allow water to drain. To do this, on the entire area make a small bias towards the runoff - holes through which water will fall into the sewer system. The stock is always equipped with a siphon - he will warn the appearance of unpleasant odors and drafts.

How to make the floor heated in the bath

The construction of the so-called, warm floor will be more efficient in terms of obtaining a warm floor in the bathroom, during the operation of which is used by water-mounted water, infrared or electrical heating.

Installation of electric heating is performed as follows:

- On top of the heat insulating layer fit into the reinforced screed of mats or electrical cables

- Heating elements are laid evenly - this will provide the same surface temperature over the entire area

- Heating infrared mats are installed before laying the tile, glue uses for fixing them.

Installation of water floor heated involves the use of pipes filled with hot carrier as a heating element. Such a floor is more economical, but the process of its installation itself will be much more complicated:

- It will be necessary to choose high-quality pipes: metal-plastic, polyethylene or copper

- For the system you will need to purchase temperature sensors, thermostat, pump

- To heal water, you will need to connect the system to the water heating device, which can use an electric boiler.

The maximum conservation of heat will contribute to the difference in the floor levels of individual rooms. The lowest floor can be in the locker room, the floor in the washing - 3 cm above, the floor in the steam room should be lifted by another 15 cm.

Since the bathroom is distinguished by increased fire hazardous, it is customary to be placed separately from the residential building. It is difficult to retain heat in a separate small size.

Therefore, heat-insulating work should be considered responsibly - they will help create a warm and comfortable atmosphere in the bath and relax.