What better metal drills: choices Instruments

Not only from professional builders, but many homemade masters periodically arises the need to process various shaped details. You can perform such work only if there is a suitable tool and the drill on the metal of the desired section and form. Those who are often faced with the creation of various parts for the assembly of metal structures, prefer to immediately acquire whole sets of drills for metal. For a single case, it is rational to buy only one type of drill. But also in that, and in another situation, the question arises, which drills on the metal are better, more reliable, stronger, so that they do not have to change them after each work unit. You will learn about all the nuances of choosing such a tool from this article.

Content

How to choose a metal drill?

Understand which drills on metal is better easy. Adhere to such criteria and familiarize yourself with the characteristics of the tool that comply with these requirements:

- shade;

- the quality and symmetry of sharpening;

- diameter;

- typical form;

- quality and type of metal;

- appointment and opportunity;

- manufacturer.

Important! If you are before buying drills for metal, clearly define your goal and designate the price of the issue, choose the right tool for work is very simple.

In addition to these characteristics, it is necessary to take into account the fact that you have a drill. For example, if you need to break the holes of a large cross section, respectively - it will also require drills for a similar diameter and length, and for this, only powerful and low-speed drills are suitable. In addition, some drills can only be used together with cooling liquids so that they are and processed metal is not burned. An exception can be a situation where you will act with the drills of a smaller cross section in series, in several steps expanding holes to the desired size.

Color drill

The first criterion for which you can independently determine the quality of the tool you suggested is its appearance, in particular, color. Experts celebrate the following features:

- Gray. If the metal looks exactly in this shade, it means that you are offered the most unreliable option - these drills have not been subjected to no processing to hardening and increasing resistance to deformation and combustion. Yes, the price of such a drill on metal will be very low, but well, if you have enough of it to complete one task.

- Black. If black drill, this indicates that it was treated with overheated steam. The result of such a procedure is an increase in strength characteristics and, as a result, extending the service life. The price of such products is somewhat more expensive than the tools of the gray germer, but is quite accessible.

- Pale golden shade. Such a color is acquired by metal drills after a vacation has been used in the manufacturing process. The main purpose of this processing is the removal of internal voltage in the censum metal and increase its strength.

- Bright golden color. These drills will cost you much more expensive, but in the alloy will be at the most durable Titan. Due to this, the friction of the drill is reduced during operation, due to which it is more convenient to do the holes, it extends its life.

Important! Determine what the best metal drills just for you, approaching the issue of buying from a practical side. If you constantly need this tool, you should not save - as a result, you will spend more time for the entire drilling process, for the purchase after a short time of the new tool, and you are unlikely to be satisfied with your purchase in the quality of the result. In this case, the output is one - buy drills of a bright golden shade. For single work, cheaper black drills on the metal will be quite suitable or with a light golden meter.

Metal Drill Dimensions

The dimensional grid is wide enough, it may differ from different manufacturers with various parameters. But there is a certain classification according to the current GOST, in which such groups of metal drills are distinguished:

- Short. This category includes tools whose diameter ranges from 0.3 to 20 mm, and the length is from 20 to 131 mm.

- Elongated metal drills. This group is represented by products with cross-section parameters as in short drills, but with a length of 19 to 205 mm.

- Long. This category includes metal drills, in which the diameter begins from 1 mm and up to 20 mm inclusive, the length is 56-254 mm.

Important! All requirements are responsible GOST 4010-77, 10902-77 and 886-77, respectively, the above list.

Marking Metal Drills

The labeling of the metal drill is determined by their diameter, as well as where they were manufactured. These rules and features can be noted:

- Drills with a cross section of up to 2 mm - marking do not have.

- Drills with a diameter of 2-3 mm - on them you will find the designations of the steel and sections of the brand.

- From 3 mm - such data as a cross-section, metal brand, including additional substances in the alloy, the manufacture of the manufacturer are applied.

Important! The labeling of the drill is an alphanumeric combination that includes high-quality products:

- the letter P is the designation of high-speed steel;

- an alphanumeric combination - denotes the content of other metals impurities in alloy, for example: M3 - Molybdenum, K6 - cobalt.

Domestic manufacturers are limited only by these labeling rules. If you decide to buy drills for metal import brands, you will find more detailed information on high-quality products:

- name of the manufacturer;

- company trademark;

- steel or alloy brand;

- section and drill size;

- recommendations for use - metal, which can be processed by one or another drill;

- accuracy class.

Important! Imported production drills are marked with HSS or DIN values. To make it easier for you to deal with such marking and choose the appropriate tool for you, the following are the recommendations for the use of some of the most popular types of alloy with such labeling.

Alloys, marking, appointment of metal drills

To deal with what exactly you need a drill, you can independently if you know which metal you need to drill. Manufacturers recommendations are reduced to the following:

- HSS-R and HSS-G. Metal drills with such labeling are designed for processing:

- steel - cast, cast under pressure, alloyed, carbon, with durability up to 900 N / mm²;

- metal alloys - aluminum, melchior, graphite, bronze, brass;

- cast iron - gray and dwarf.

- HSS-G CO 5. If the drills are such marking, the strength indicator in this case is limited to 1100 N / mm². They are appropriate to use for steel:

- stainless;

- carbon;

- thermally improved;

- acid and heat-resistant;

- alloyed;

- non-stitched.

- HSS-G Tian / Tin. For the manufacture of tools from this type of metal, titanium-aluminum-nitride spraying is used. As a result, the surface becomes resistant to corrosion, perfectly cuts the metal and can be saved for a long time in original form. They are suitable for processing alloys of various origin with durability up to 1100 N / mm². The list of recommended metals includes:

- cast iron - gray, with spheroidal secretions of steel, graphite, dust;

- alloys - Melchior, brass, bronze;

- steel - Litua, including under pressure.

In addition to these steel grades, other metals for the production of drills are used:

- Cobalt. Due to the inclusion of this element in the alloy, the tool acquires high characteristics of strength, resistance to deformation during mechanical and thermal effect. Therefore, they are suitable even for drilling holes in carbide metals, for viscous alloys and non-ferrous metals. Cobalt drills for metal are more expensive than ordinary, but it is easy to find them today - many manufacturers of construction tools produce entire series of such models.

- Carbide drills for metal. This group of goods is present by a separate line, and the composition of raw materials for the manufacture of such drills may differ from different manufacturers. The main advantages of such a tool are to process the metal of a large thickness, from the most strong and solid alloys, has a very sharp, one-sided sharpening angle, which greatly simplifies the course of work.

Types of metal drills - body shape and tip

The variety of the current range of metal drills is very large. To greater extent, this is because they are used not only for direct purpose - for the drilling of metal, but also often use for other types of work during processing:

- wood;

- plexigla;

- ceramics;

- plastic;

- concrete.

Important! Each of the species is suitable for a particular range of work due to the fact that the design is developed in a special way, taking into account all the nuances of one or another material.

Design of drill

The main elements of the drill is:

- cutting part;

- shank;

- working surface for cutting chip from the hole.

Allocate 2 main groups of metal drills by these features.

Flat drills

Otherwise, they are called perovy. The models can differ in the shape of the cutting surface. Main advantages:

- absolute insensitivity to skews during work;

- simplicity of design;

- cheapness.

Disadvantages:

- reduction of the diameter of the working surface during sharpening;

- there is no automatic chip discharge from the hole.

Frequently used variety - these are the drills of cousin for metal. There are on sale separately and whole sets with a cross section in the range of 6-60 mm. The conical metal drill is more intended for use on special equipment - a drilling machine or in a two-piece drill. The name identifies itself - the shank is sharpened in the form of a cone. Perfectly suitable for spending the holes of a large cross section.

Spiral drills

These metal drills are more popular for today and it is their varieties that are widely used. In shape - these are rods in the form of a cylinder, over the entire surface are 1 or 2 grooves-deepening. With their help, the chips from the hole immediately, in the process of work, is displayed out. Depending on how the shank drill on metal, distinguish:

- Ordinary cylindrical metal drills - usually diameter does not exceed 12 mm. Suitable for both professional needs and solving household problems. This group is the most popular type of metal drills.

- Coronated metal drills. The metal drills with such a shank are used in the case when it is necessary to do a large hole - with a diameter of 30 mm. It looks like a tip as a crown with frequent teeth, most often decorated in the form of a hexagon. More suited these drills for fine metal.

- Thread drill. This tool model has a direct purpose - the design of the hole with a thread of the desired section. The diameter of the drill itself is usually taken on 1 unit, a millimeter less than the opening section.

- Step metal drills. This species is universal in terms of the fact that with the help of one tool you can make openings of various diameters. The only nuance - apply them is recommended only for a sheet material, the thickness of which does not exceed 2 mm. The diameters of such metal drills are up to 30 mm. The price increases as the cross section increases.

- Left-sided drills. Their scope of application is limited - only for winding the metric: screw, bolt, self-press.

- High accuracy drills. These tools are chosen mainly by those who are very important than the high accuracy of the result. The accuracy class is denoted by an alphanumeric combination - A1 or B1. The higher the accuracy class, the higher the price of drill on metal.

Drill manufacturers

A very important point when buying drills for metal - manufacturer. The fact is that good consumer reviews and the optimal price is not all factors. The reliability and verification of the brand affects the quality of sharpening, alloy strength, wear resistance, anti-corrosion and fire-resistant tool properties. Therefore, do not attempt to save greatly, prefer proven companies whose products will serve you to solve not one task.

According to the reviews and positions on the market, the best is considered drills for metal:

- THE USSR. If you have found a tool with such marking, without thinking, take it. All professionals note the strength of the used alloy, reliability, the longest period of operation, less abrasability of the cutting elements.

- Ruko. This brand also gained popularity at the expense of good quality and reasonable pricing policy. The model range of TL 3000 is especially in demand - these are multifunctional drills with crossed sharpening with a spraying of various modifications of titanium. More applied with those materials, with the drilling of which the chips of large and medium length is formed.

- Bosch. This company supplies many different tools of excellent quality. Drills are included in their number. Those who have to constantly engage in repair and construction work, probably know that Bosch is one of the best solutions today.

- Haisser. Power drills are considered tools from this brand. They are used in industrial, and in domestic conditions, even with extreme load. The cooling of the drill during operation is achieved due to the titanium alloy, and the sharpening angle of 135 degrees and the mesh grinding gives the rapid result of entering the material and removal of chips.

- Bison Domestic manufacturer, who also gained popularity from homemade craftsmen and professionals, mainly due to an acceptable price and long life. The series "Cobalt" is particularly interesting, the accuracy class of which corresponds to the highest - A1, and the characteristics of GOST 10902-77.

What else needs to know about metal drills?

After a certain service life of any drill it must be sharpened. This procedure is possible to perform with your own hands at 2 conditions:

- you purchased a tool from a reliable manufacturer that does not save on the quality of the metal;

- you follow the rules of sharpening technology.

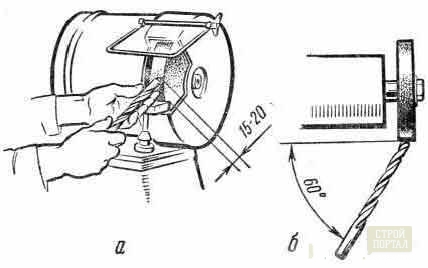

You will be able to perform an independent sharpening of the drill if you adhere to such a scheme:

- Be sure to start the work of protective clothing - glasses, gloves.

- Prepare containers with coolant. For this purpose, you can use water or machine oil.

- Check for the good apparatus.

- Tightly press the drill to the grinding circle and consistently process the surface, starting from the rear.

- Adhere to the suitable sharpening angle:

- steel - 140 degrees;

- bronze - 120;

- copper - 100.

- Treat the working part of the drill while holding the sharpening angle.

- Do not concentrate attention exclusively on the tip - the entire surface, side, including, should be well sharpened.

Important! Before you immediately sharpen the instrument you need, pre-practice on those tools that you will not be easily useful. So you can fill your hand and already on the drill you need to do everything right.

Video

Review the video in which it is clearly shown how you can make a sharpening drill with your own hands.

Conclusion

Now you know everything about how to choose the right drill and which of them are best for your goal. Consider all the criteria when buying a tool and then you do not have to pumped out in the near future the need to acquire a new drill. It will last for a long time, and the quality of the work performed will meet the specified requirements.