Concrete Rings for Well Building materials

Concrete rings for the well are pretty popular products. In the private sector, they are used to arrange water supply and sewage systems, gas stuffing and drainage communications.

Content

Varieties of concrete rings

In the production of concrete rings, high quality cement and additives, which improve strength indicators are used. It is clear that the manufacture of these products in industrial workshops is carried out using special equipment. Although it is possible to make rings from concrete at home.

There are the following types of rings used to arrange a well:

- wall;

- reference;

- dobly;

- with bottom;

- castle.

Wall structures are universal and used in the device of all types of wells. In most cases, they are reinforced concrete products. Mounted wall rings on each other. For their reliable fixation, joints are sealed with cement mortar.

Wall rings made of concrete is undesirable to apply in areas with rolling soil. These products do not differ in high strength. Each soil displacement can lead to design deformation.

The use of support concrete rings is appropriate if the well is located on the movement of the vehicle. This technology provides for a hatch device over the well. The main purpose of the support structure is the arrangement of the hatch with the lid at a given level.

Non-standard dimensions of good concrete rings for wells allow you to create a design with an optimal depth. Production of good products is almost always carried out under the order. Their installation is made in the bottom of the well, and the installation of wall structures is set on top of the fair rings. The joints are also treated with cement mortar.

Also similar to the wall structures of the ring with the bottom. The only distinctive feature is the presence of a concrete bottom. To install such a ring qualitatively, you will need to create a perfectly smooth surface of the well. The weight of such a concrete ring for the well is significantly higher than the mass of ordinary products. What can cause some difficulties in the implementation of installation work.

Rings for wells with a lock still called puzzle. At the bottom of the concrete ring consists of ridges that are connected to the castle elements of the upper part of the product. As a locking mechanism, folders are in the joints of the rings. Thanks to the mechanical bundle, a high-quality tight construction of the structure is ensured.

Naturally, the price of a concrete ring for a well equipped with a lock exceeds the cost of ordinary wall products. But such a design will serve much longer. In addition, the castle rings are characterized by increased moisture resistance and the low probability of the horizontal shift of the well. Therefore, they are not terrible "floating" soils.

The importance of reinforcement and labeling of structures

This process is not a mandatory requirement. But the reinforcement of the rings to implement, yet, it is recommended. Thanks to this procedure, products become more durable.

During the reinforcement of the concrete ring under production conditions, the method of vibratingressing is used. Thanks to this, the ring is homogeneous and dense. What makes it moisture-resistant and preserving its shape.

Reinforced concrete rings have a number of undeniable advantages. They are resistant to compression loads. The presence of a steel frame gives products maximum strength and increases their operational period.

In addition, the installation of structures does not involve the presence of special knowledge. Concrete rings are easy to repair and clean from various contaminants. If necessary, they can be replaced.

The manufacture of concrete rings occurs, taking into account the established norms (GOST). Marking products is carried out depending on their size. The inner diameter of the concrete ring for the well can be 70, 80, 90, 100 and 200 cm. Naturally, when the arrangement of the pit should be taken into account the external diameter of the mounted rings. The minimum height of the rings is 10 cm, the maximum is 100 cm.

Marking rings Consider on the example. The product with marking KS-7-10 suggests that the concrete ring has an inner diameter of 70 cm and a height of 100 cm. If we need to purchase concrete rings with a height of 60 cm and a diameter of 100 cm, then their marking should be KS-10-6.

The main stages of creating a well

The manufacture of wells from concrete rings is divided into such steps:

- digging care;

- aligning its foundation;

- sand cushion device;

- montage of rings;

- waterproofing work.

If the rings are installed for the sewer system, the place for the pit is necessarily coordinated in the sanitary service. Drain is done in such a way that concrete rings are placed without problems in it. The presence of spare space will greatly facilitate the conduct of the entire set of installation work.

At the next stage of the device, the well made of concrete rings is made to align the bottom of the bottom and the creation of a sandy pillow with a thickness of more than 30 cm. The gravel pour over the sand. Both layers thoroughly tram.

With the help of a lifting crane on the bottom, the first concrete ring is stacked. It can be both with the bottom and without it. Installation of the remaining rings is accompanied by a ventilation system. In order for the air to be in sufficient quantity, the pipe should perform above the surface of the earth by 0.7-0.8 m.

Immediately concrete all the joints between the rings. The outer part of the rings is covered with rolled waterproofing materials, inner - penetrating waterproofing compositions.

Nuances device sewer well

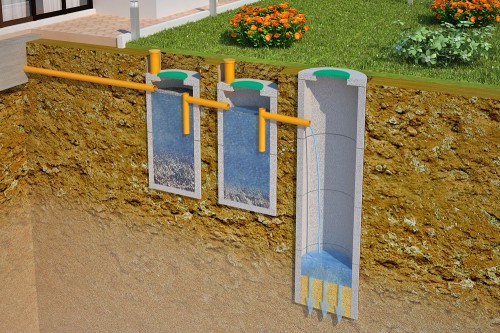

In most cases, concrete rings are used when the sewer septication is consisting of three cameras. The first chamber produces primary wastewater treatment. There is a sedimentation of solid particles to the bottom. This chamber is purified once every 3-4 years. This uses an asserenitator or mud pump.

The second chamber is connected to the first with a pipe laid under the tilt. In this part of the septic, an additional cleaning of wastewater from impurities occurs, after which the liquid enters the drainage well made of concrete rings.

The third chamber is the final element of the local sewer system. It is selected in peeled wastewater through gravel into the soil. A close occurrence of groundwater leads to a slowdown in the wastewater treatment process. Therefore, the pump is additionally used.

When the sewer well, the following should be taken into account:

- It is not recommended to use concrete rings in permafrost conditions.

- When creating a hermetic design, the depth of the well should not be more than 3 m. It makes it difficult to show off the stocks by the assessing agent.

Video about the device Well made of concrete rings: