Paint for concrete surfaces: selection and instructions for use paints and varnishes

Concrete is the most popular and universal building material, which has a huge amount of advantages, including durability and the highest strength. At the same time, concrete surfaces themselves look not very presentable. Within the production, educational institutions and warehouses, concrete is used without any restrictions, but in houses, in shopping centers, in clubs, as well as in other institutions, concrete must be stained. With the help of paint, you can not only improve the unattractive type of concrete, but also protect the surface from various negative factors.

Content

Main features of staining concrete surfaces

Many could see that in production workshops, concrete is most often used, which no protective coatings are applied. It is worth noting that the upper layer of concrete is very often covered with dust, as well as by many other flaws, which after construction work is incredibly difficult. Considering that in production, there are very often unfavorable conditions, a dusty surface is far from the most serious problem that rarely attention.

In residential premises, the presence of a dusty surface is unacceptable. The cheapest and effective way to get rid of yourself from such things is the acquisition of paint, when using the surface will become almost invulnerable to most negative factors.

It is also worth noting the fact that in our days there is a huge list of solutions, with which the concrete surface becomes attractive and durable.

The choice of paint in this case depends on the conditions in which the concrete will be. Recently, special binders of paints are increasingly used, with the help of which the concrete surface becomes resistant to mechanical and abrasive influences. This option is best suited for production, where, with the help of various devices and equipment, it is possible to accidentally create a crack in the concrete.

Use acrylic paints

Most likely, it is an acrylic material that is the most popular solution for coating a concrete surface. Acrylic paints are aqueous compositions that include resins and polymers. After dried acrylic, a peculiar protective film is created, which has vibration resistance. This is what lacks a concrete surface.

It is also known that acrylic paint will not allow concrete to begin to crack, as often happens under normal conditions. In addition, this material will perfectly protect the concrete at too high temperatures, as well as with high humidity. Acrylic paint is characterized by environmental friendliness.

To apply paints to the surface of concrete, brush, sprayer or roller are most often used - depending on the amount of work. Acrylic dries very quickly, so it is possible to fully exploit the room the day after work. Often, two layers of this paint are applied.

Epoxy paints for concrete surfaces

The main advantage of epoxy paint is the presence of high resistance to abrasion and mechanical damage. In this case, this type of paint has no full-fledged competitors. Unfortunately, epoxy paints do not provide a colossal range of color solutions, but this material is intended primarily to protect the surface, and not to increase its external appeal.

Epoxy paints consist of two components that are mixed with a construction mixer.

It is worth saying that the concrete surfaces of workshops, automotive workshops are most often covered with this material. Also surely, many will interest the fact that epoxy colors cover concrete surfaces that are under the action of precipitation and sunlight.

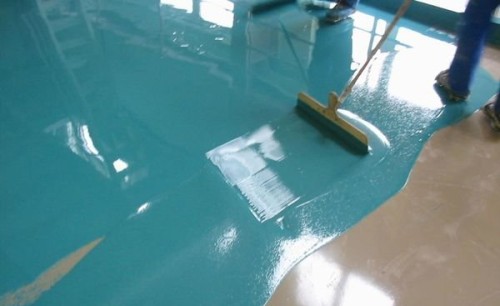

Epoxy material is an excellent waterproofer, which is used in the overwhelming number of cases. Apply this paint is best on fresh concrete, this will increase the efficiency of the protective coating.

Like acrylic, epoxy paint is applied in 2 layers with similar building accessories.

Features of using polyurethane

Polyurethane is one of the most modern materials by which protective surfaces are created with the most diverse properties. In this case, much depends on the composition of the enamel, which is used in a specific situation. Just as in the case of epoxy paints, polyurethane consists of two components that need to be mixed, and the resulting mixture is applied to concrete.

Surely many do not have to do the fact that after applying, the polyurethane will dry for 2 weeks, and sometimes you have to wait even longer. During the first 6-10 days, the material is gaining mechanical strength, and only at the beginning of the second week reaches the necessary values \u200b\u200bof the chemical component of enamel.

Despite this, polyurethane is an economical material on which too many means will not need to spend.

Most people make a choice in favor of polyurethane attracts a glossy surface of concrete, which is formed after applying the polymer material.

Other coating options for concrete

There is still a lot of other options, however, for applying to the concrete surface, they are extremely rare. High-quality analogue of polyurethane are urethane-alkyd paints. The main feature of this coverage can be called the presence of dozens of diverse color options, with which you can turn the usual gray room into bright and colorful. Unfortunately, this paint is distinguished by not the best protective qualities, but two layers of Uretan alkyd enamel will allow concrete surfaces without any problems for long years.

There are also acrylic-silicone enamels that are practically not used as coatings for concrete. Despite this, the material has a small price and flexibility to use at various temperature modes.

The right choice of paint

Very often consultants in building shops face people who want them to advise the best paint for concrete surfaces. It should be noted that all materials presented above are best suited to protect concrete surfaces. The choice of one or another paint should be based on the existing temperature modes, the conditions of use of the surface, as well as on the basis of humidity indoors.

Thus, after analyzing each of the aspects presented, one or two options will remain. If the remaining enamel options are approximately the same, you should make your choice in favor of the products of authoritative manufacturers.