Installation of sewer tubes Plumbing

The main purpose of sewage pipes is the conclusion beyond the limits of the settlement and industrial enterprises of sewing water.

Content

Installation of sewage pipes: What to choose?

Today, cast-iron and plastic pipes are used to arrange the sewage system, however, preference is given first, since in addition to convenient installation, they have good operational qualities.

Properties of sewage cast iron pipes

Advantages:

- corrosion resistance;

- environmental friendliness;

- silent;

- fire safety;

- capable of withstanding heavy loads without disrupting integrity and compounds;

- the optimal diameter allows self-cleaning;

- resistance to the effects of aggressive substances;

- high wear resistance.

Disadvantages:

- the properties of this material may affect: seismically active zone, weak soil and solonchard soils;

- installation of cast-iron sewer pipes involves special accuracy and accuracy in operation;

- the compound of their termination is a long and labor-intensive process;

- with their help, not all projects can be implemented;

- when installing, compliance with accurate centering;

- it should be limited to the number of differencepal pipes;

- sliding such a system must be up to 10 m;

- metal capacity;

- considerable weight;

- the rough inner surface creates waterstock resistance;

- high price.

Properties of plastic sewer pipes

Types of plastic pipes for sewage:

1. PVC pipes (gray or orange color).

Peculiarities:

- resistant to minus temperatures;

- possess good strength;

- have an increased mechanical and chemical wear resistance of the inner surface;

- the short-term operating temperature is 80 ° C, the maximum is 40 ° C.

By class of strength, they are divided into:

- average (equipped under a small carriageway);

- light (not used under the roads and mounted on a small depth);

- heavy (paired under large industrial enterprises and motorways).

2. Polypropylene tubes (gray).

Peculiarities:

- unlike PVC pipes, polypropylene are less rigid;

- have increased heat resistance;

- can function at temperatures up to 80 ° C;

- scope - sewer internal networks;

- burn badly;

- are not suitable for arranging external sewage and laying it in the ground;

- have insufficient rigidity;

- may be damaged by rodents.

3. Corrugated polyethylene pipes.

Peculiarities:

- installation of corrugated sewer tubes is made exclusively in the outer sewage;

- they are placed in the ground to a depth of 15 m;

- the outer corrugated wall gives them increased strength;

- the smooth inner wall provides a normal movement of water;

- sometimes such pipes are produced from polypropylene.

Settlement Pipe Mounting Rules

Plastic sewer pipes, the installation of which is carried out by fittings, provide the highest quality connection. If the butt welding is used, it is recommended to be applied to the device of the hidden pipeline.

The principles of the installation of the sewer system can be divided into:

- installation of sewage pipes in the house (internal);

- external installation of sewage.

Internal System Installation Rules

- creating the installation of sewage, it is desirable to use as a minimum amount of joints and turns;

- it is necessary to use pipes with a diameter of 50-100 mm;

- the angle of tilt pipes may vary from 1-2 cm / m;

- when equipped with pipes made of plastic, it is recommended to use additional lubricant;

- on each turn, audits should be provided;

- when fixing the material with plumbing devices, transitional cuffs made of rubber and sleeves should be activated;

- the risers must be fixed from the bottom up with the help of clamps;

- pP tubes are cut with a special hacksaw or a grinder;

- when installing sewer pipes in the apartment from the residue of the material, the latter are connected with the help of repairing clutches;

- docking pipes from PP using the skin does not imply additional sealing.

Outdoor sewage installation rules

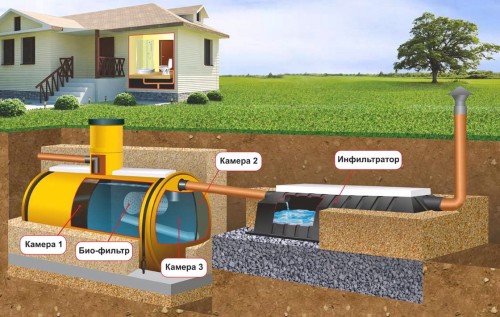

- such sewage is installed in the trenches, equipped below the level of ground freezing;

- if necessary, as well as with the depth of laying the sewage system to 0.5 m, it is recommended to isolate with fiberglass;

- on the bottom of the trench, the sand cushion is lined with a layer of 10-15 cm;

- the laid sewer tube with sides falling asleep with sand and trambed;

- on turns, as well as every 25 m, revision wells are shown;

- the finished system is displayed in a cesspool or connects to the septic.

Installation of sewer pipes with your own hands

Installation technology of sewer pipes

- installation of the sewage system begins with the scheme of the future network. So it is necessary to visually try the project to the place of its future location and make an approximate drawing. The turns and all the necessary shaped parts will be marked here. In addition, you should calculate the overall footage of pipes with a small margin;

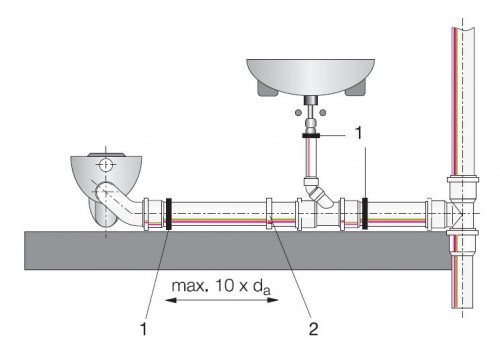

- if the system's branches are located in one horizontal plane, then all compounds are installed using brazy tees and are performed with removal at an angle to 45 °;

- each turn should be equipped with audit access;

- it is strictly forbidden to fasten the pipes in the horizontal plane at an angle of 90 °;

- the riser for the sewage system should be equipped with a ventilation pipe;

- pipe fannaya is derived from 0.5 m level of roof;

- laying sewage can be carried out inside the walls and gender;

- the internal installation of sewage pipes, the price of which depends on the building material used, is created with a slope of 1-2 cm for each meter of the pipeline;

- greater bias are admissible exclusively in areas of not more than 1.5 m from the riser;

- between the concrete and the sewer pipe, it is not recommended to create air gaps;

- the thickness of the plaster layer should be from 2 cm;

- carrying out the gasket of pipes outside, their fixation is carried out by conventional clamps with a 10D fastening step;

- the risers are fixed every 1-1.5 m;

- from the wall to the pipe, the riser should be a distance of less than 5 mm;

- mandatory is the fastening of the pipeline under the socket.

Video installation of sewer pipes: