Wall insulation Baths do it yourself Baths, saunas and pools

The wellness effect of the bath is ensured correctly selected materials. When steaming steam room, harmful substances are distinguished into the air.

Content

The insulation is needed, capable of maintaining the heat and at the same time not harm to health. Your task is not only to choose the insulation, but also competently produce its installation.

What materials are suitable for bleat insulation

- So that in the drilled bath for a long time heat, it is necessary to insulate the walls of the bath on both sides. Internal thermal insulation insulation must be environmentally friendly and respond to sanitary standards.

- Mineral wool-based insulation have a low thermal conductivity. It has high hygroscopicity, therefore needs reliable waterproofing. For interior decoration, its use is undesirable. Under the influence of high temperatures of the Ministry of Internal Affairs, harmful substances. When using the Minvati indoors, waterproofing is necessary not only to protect the material from moisture, but also as a barrier from getting harmful evaporation to the room.

- Polystyrene also highlights harmful substances when heated. For this reason, it is not used for the internal thermal insulation of the bath.

- Finnish insulation for SPU SAUNA-SATU bath has a high thermal insulation ability. Produced in plates of 600x1200 mm. Thickness 30 mm. The material does not support burning. Does not absorb moisture. Due to the fact that the material during heating does not give harmful evaporation, the SPU SAUNA-SATU insulation is recommended for indoor use. In particular, for the pair and sauna finish. Installation is carried out directly on the wall without the crate device.

- The insulation of the walls of the bath outside the goal is to protect the construction structure from atmospheric influences - cold air and precipitation. The methodology of insulation is chosen depending on the building materials from which the bath is built. For external insulation, almost any kind is suitable insulation.

- For insulation of the walls of the frame bath, you should choose a material with a slight weight so as not to create an excessive load on the walls.

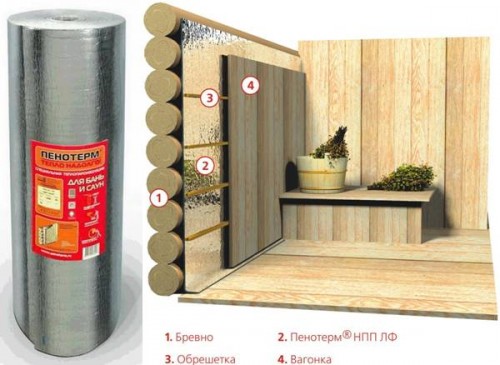

- Especially for finishing a steam room produced foil heat insulation Penoterm NPP LF. This insulation is made of foamed polypropylene NPP, on the one hand is illuminated by aluminum foil. Combines the quality of heat and waterproofing. Material is resistant to high temperatures. It has a thickness of 3 to 10 mm.

- For insulation of brick walls, having a high thermal conductivity, a thickness of 8-100 mm will be required. For wooden baths, a heater is suitable with a thickness of 3 to 5 mm.

- Special materials are used for the pair-and waterproofing device. Hexa company produces films and membranes Izospan. The proper waterproofing device helps to maintain the properties of the insulation and prevents the formation of condensate.

How to perform the insulation of the walls of the bath

Wooden Frozen Heating Order

On the insulation of the walls of a wooden bath must be taken care of its construction. To do this, there is an interventic insulation for a bath. It is placed between log logs. Such insulation have a natural basis from felt, jute, hemp hemp, linen pacle. Natural insulation provide natural air exchange indoors.

Jute fiber does not rot and does not absorb moisture. The durable insulation is flax felt, combining the strength of flax and water repellent properties of the jute.

- When the wall is erected, the insulation laid between the crowns.

- After complete assembly, the logs close the junctions of the logs, sealing the insulation with a special panty.

- Extraked seams are sealant.

How to insulate the walls of a bath of bricks or foam blocks outside

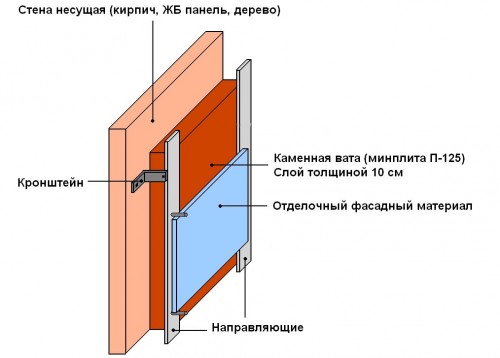

Warm bath outside wall brick by using ventilated facade device. On the wall mounted frame, and then attach the insulation and waterproofing. The paper concludes with a covering frame materials for building facades - siding or plastic lining.

The order of installation of ventilated facade is as follows:

The order of installation of ventilated facade is as follows:

- Treat the surface of the wall antifungal primer.

- Set vertical aluminum profile is at a distance of 0.8-1 m from each other.

- Fill the space between the profiles layer of insulation.

- Close joints between slabs of insulation material tape or fill adhesive composition.

- Secure waterproofing using rails.

- Install the horizontal rails of the profile for securing further cladding material.

- Obsheyte ready to frame a finishing material for facing facades.

insulation technology walls inside insulation bath Penoterm

- Insulation mounted on the vertical walls of the bath. Wooden surface does not require training.

- Unwind roll and cut into strips of the required amount with an allowance of 10 cm to the height of the walls.

- Fix the material using a stapler foil side on the inside of the room. Material attached overlapped.

- Excess material along the length of not cut and wrap onto the floor. Such mounting method ensure condensation output.

- Glue joints metallic tape.

- Install the wooden crate for the subsequent installation of siding.

- Mount the wooden lining.

Wall insulation brick inside baths

The principle of mounting the inner insulation wall bath of brick or foam blocks is the same as the outside.

The difference is that the bath is mounted inside a wooden lath, and not metal.

After laying the insulation and waterproof membrane or film lathing sheathed wooden lining.

Wall insulation baths with their hands, made by all the rules, will help keep the heat in the bath and keep your health.