Binding of a column and screw foundation with their own hands Construction,Building materials

Any foundation, even if the most small and easy building, I want to make the most durable and durable. In the case of a columnar foundation, this may contribute to the creation of a strong strapping. In this article, you will learn how to make a strapping of the foundation with a bar with your own hands.

Content

General

First of all, it is necessary to figure out that there is a blockage and what materials for this are used for different types of bases. Screw foundations consist of special screw piles. This is a relatively new construction method, which has deserved widespread popularity in Western countries and in the post-Soviet space. It allows you to build a strong and reliable base for any construction, regardless of the type of soil and landscape features. Screw piles are very comfortable there, where there are significant differences in height, for example, if you need to build a house on the hillside.

The spiral pile is a metal pole with threaded blades at the bottom, which is screwed into the ground. Thanks to the welded blades, it is not only firmly "sits" in the ground, but evenly distributes the mass of buildings throughout the area.

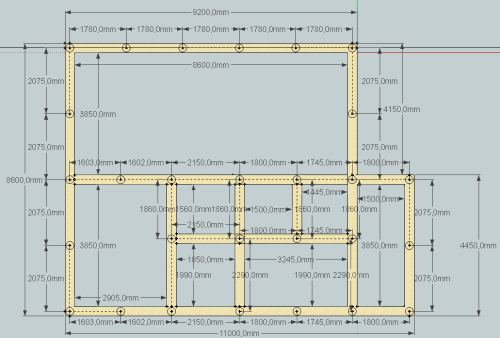

Classic columnar foundations are constructed from concrete, booton, asbestos-cement pipes, bricks or wood. To do this, they make markup in accordance with the previously developed plan, after which there are strictly vertical pits at the points of intersection of walls and a strong load. The distance between the columns should not exceed 2.4 m. If the distance is larger, there is an additional support between the two elements. The choice of material for the construction of poles depends on the load on the foundation, the characteristics of the soil and financial capabilities. The most short-lived is the wooden base (serves 15-30 years) from pine or oak, but the boot concrete or qualitatively folded brick poles will preserve 70-150 years.

What is a strapping

For a better understanding of the term strapping and its destination, it is not bad to consider the features of the pile foundation. As a rule, it is equipped for small and relatively light buildings: guest houses, sheds, verandas, terraces, arbors, etc. Unlike a tape and monolithic foundation, where contact with the soil occurs throughout the area of \u200b\u200bthe house, the columnar only points to the soil, thereby reducing the effect of powered forces and protecting the lower part of the floor from destruction. The only drawback - with this basis it will not be possible to make a cellar or basement. Despite this, many are preferred to such a type of foundation, since it allows you to save a lot of money, time and strength.

Poles or piles deepen into the ground to a certain level, depending on the degree of drainage of the soil and the location of groundwater. The lower part of the post must be below the waterproof point, otherwise in the spring, it simply pours out or overflowing support. But even if the poles of the discharge in all the rules, it does not guarantee the maximum stability and strength of the building, especially if we are talking about a residential building. Especially for such cases was invented a binding. It is a wooden or metal frame - beams or randbalki, binding all the poles with each other. At the same time, the strapping is a good help for attaching walls, overlap and floor.

Bar for strapping

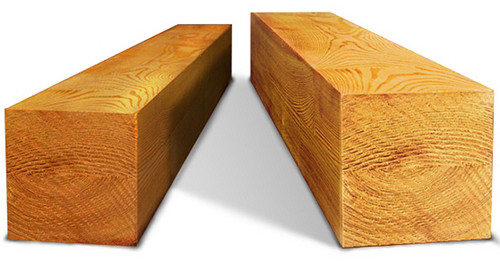

The strapping made with the help of a bar is called Scarlet. This is the most common type, since it does not require complex professional skills and participation of severe construction equipment. The timber is a tree trunk, cropped from 4 sides in such a way that a square or rectangular cross section is equal along the entire length. Most often it is used to straighten the foundations under the baths, logs and wooden verandas.

Basically, coniferous rocks are chosen for the construction of painters, since they have natural antiseptic properties and are not so strongly susceptible to deciduous. Another weighty argument - the cost of a pine timber is much lower than deciduous or oak. To get a solid and high-quality strapping, the cross section of the bar must be at least 150x150 mm. It is very important to choose the right material - it should be sufficient dry (the level of moisture is no more than 18%), otherwise, after drying, the woodlock can turn it, it should not be cracks and should be as few bitch.

Useful advice: Buying material, add to the total number of 10-15% about the reserve. This rule concerns the purchase of consumables for all large-scale work, whether it is the creation of a woodwork or laying the roof tiles.

After purchasing a bar, it is necessary to process it - to impregnate with an antiseptic for the tree so that insect pests inside the insects inside, and the mold did not appear, cover the flame to protect against fire. In the case of coniferous rocks, this is a very important step, as they contain a large percentage of combustible resins.

The glued bar is deserved separately - the material obtained as a result of the gluing of several small-seen bars. First, all components are subjected to drying, select marriage, after which they glue with a special composition under the press. At the exit, it turns out a high-strength lap of excellent quality, which has all the advantages of natural material and practically deprived of the main flaws of wood. Another important point - the glued bar always has accurate sizes, since it is manufactured by the factory method. Some types of material have pre-made grooves and protrusions for a quick and simple connection. But the main plus of any glued timber lies in its high hydrophobicity and thermal protection. Since wood passes through a powerful press, it becomes much more densely, which means almost no moisture and does not support burning. And if you additionally handle the material with antipirens, you can be completely confident in the safety of future housing. Naturally, the price of the foundation of the foundation of the timber is much higher than the usual "monolithic" wooden beams, but also the benefits are obvious.

Styling technologies

The blocking technology of the foundation of the bar may flow across several scenarios. Modern specialists have allocated three types of installation, distinguished by high efficiency and reliability.

Methods of laying strapping:

- Threaded - this method is relevant for wooden piles of high strength and with a large cross section. The calculation of the thread depends on the thickness of the pile and is the determining point on which the result of the work depends.

- Welded - As you can guess, welding is used to create a metal strapping on metal screw piles. By the way, this is the only successful option, because no wooden strapping can boast of such strength and durability, if you attach it to the metal pile.

- Clamps - a universal way to install strapping applicable for any wooden piles, even if they are distinguished by a small thickness. In some cases, the compound of clamps is relevant for some types of steel piles.

The choice of method of installation depends on the material used, the desired quality and the thickness of the foundation base.

Regardless of the selected strategy, you will need the following tools and materials:

- laser or water level;

- metal corners;

- self-tapping screw;

- anchor;

- waterproofing material (rubberoid);

- olife for impregnation of wood;

- hammer;

- welding machine (if you work with metal).

Below we will look at each of the installation methods in more detail.

Threaded way of strapping

Immediately reveal you the secret of the experienced builders - in order to achieve high quality work during the strapping of the screw foundation by the timber, you can use two technologies at the same time - use threads and clamps. As a result, the timber will hold hard to hold the foundation as long as possible.

The easiest way is to plant a ram on the thread when the screw piles stand on the ground in the form of an inverted letter "P". First take the timing of the desired length and have it between two racks. In front of this, the rubberoid segment is attached to each pillar - putting the tree directly on the pillar cannot in any case, otherwise it is from this place and the trouble will begin (cracking, abrasion, refurbishment, rot). For a lot of reliability, rubberoid should be wrapped with a oil. The lateral racks are attached with self-draws, and to the lower base - anchors or studs. After fixing, the bar bother with a hammer.

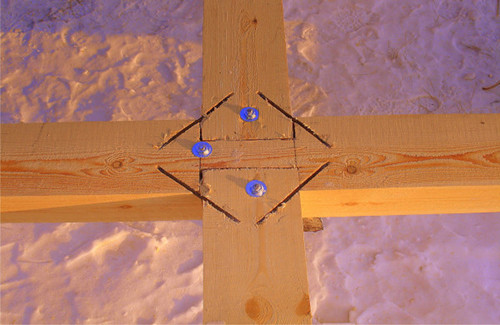

To ensure greater stability of the strapping, all external angular compounds are enhanced by metal corners or spikes. Steel corner should be selected according to the size of the corner of a bar with pile, and to screw it best with self-draws.

Clamps for strapping

It is possible to mount the baboons on the clamps if the foundation pillars cost anyhow, only not in the form of an inverted "P". The essence of the work is quite simple: long rectangular bars are imposed on the top of each pile, attaching them with welding (metal) or self-draws (timber). During the connection, it is necessary to control the horizontal plane, for which the level is useful.

Thus, the bars are superimposed throughout the perimeter of the foundation, after which there are wooden beams between the pile of these bars, so that the letter "P" is fastened. Clamps in this case are called these intermediate bars. They allow you to create a stronger connection. Ends of BRUSIV subsequently fasten with pile with steel corners or threaded fasteners. After fixing, each element is tested on sharpness - ideally no element should be fused.

Alternative way of strapping

To implement an alternative installation technology, the strapping you will need a chainsaw, level, roulette and several identical smooth and well-dried bars. Also, it will not hurt to enlist the support of several people, since in two hands with such work can not cope.

First you need to docile bars. To ensure the appropriate compound, cuts should be made from above and below, and then lay the elements at right angles. If emptiness remained after the connection between the saws, they must be fill in jute.

During the construction of a church, sometimes the first crown on the base of the foundation, as a result of which it performs the function of the lower strapping. But this can be done only if the lags of the floor cut into a couple of crowns above.

Tips from specialists

Finally, we suggest you familiarize yourself with useful tips from professional builders and self-taught masters. The binding of the column foundation of the bar is no less important work than the basis of the foundation itself, therefore, before being taken to practice, it is better to study all the available theory.

Useful tips:

- All piles must certainly be the same height, which you need to make sure before creating the strapping. Otherwise, you will not succeed to dock all its elements, and if it turns out, the walls of the house built on the foundation curve will be of different heights.

- In the process of fixing the bars to the pile, it is necessary to monitor the location of the attachments of the self-tapping screws - it should be strictly in the center. It depends not only to the uniform distribution of load and strength, but also the integrity of the wooden bar - if you shift fasteners into one of the sides, wood can crack.

- Before buying a bar, consider that the width is twice the width of the pile or the foundation column.

We offer to familiarize yourself with several videos on the strapping of the foundation of the bar, in which you will find not only the visual use of technology, but also resourceful solutions of the Mathers, allowing to reduce costs and labor costs to a minimum:

In fact, it is important to follow only two rules - buy a high-quality bar and strictly adhere to the installation technology. The construction of the foundation, even such simple, as a column, does not tolerate a rush, so first create the most likely project, and then gradually realize it in life. We hope this article will help you build a high-quality and durable foundation with painter.