Foundation Panels: Material Features and Mounting Rules Building materials

During the finish of the facade of the house, you need to take care not only about the walls themselves, but also about the foundation. The building base must be decorated beautiful and reliably, since it will be the highest loads. In this article we will tell about the panels for the foundation, their features, advantages and methods of installation.

Content

Popular Finishing Options

The easiest way to design the outside of the foundation can be considered the usual shocking. But if you want the finish to be durable and durable, and also possessed high decorative characteristics, pay attention to other popular materials for cladding, they include:

- vinyl decorative panels for the foundation;

- base polypropylene siding;

- fake diamond.

Each of these options would like to describe in more detail:

- PVC panels for the foundation, the people called vinyl, are two-layer parts made from polyvinyl chloride. The two-layer material provides its high strength and reliability, since one of the layers is responsible for the preservation of the physical properties of the finish, and the other layer protects the lining from a variety of adverse factors. Such panels are universal, they can be mounted on any surfaces in any parts of the buildings. Vinyl does not rot, does not mold, it moves well any temperatures, it is not damaged by microorganisms and parasites, and also protects the building from the penetration of dampness and moisture. Such a finish does not require careful care and is needed by ordinary water.

- The base siding, made on the basis of polypropylene, is more durable in comparison with the previous option, as well as more resistant to external influences. The reason for this lies in special stabilizers, which are part of the material, as well as in a large thickness of such panels. The base panels are not susceptible to rotting, damage to fungi and microorganisms, do not flock, do not let in the house moisture. Their price is quite accessible, they cost a little more than vinyl siding and significantly inferior in the cost of natural stone. Such cladding is able to serve dozens of years, not losing their performance and high decorativeness. Among other things, the base siding can simulate almost any surfaces, which makes it possible to apply it in the implementation of some designer designs. The base siding is made in such a way that even the person who does not have specific construction skills will be able to establish it. The decoration of the base of vinyl siding is carried out with minimal wages and time.

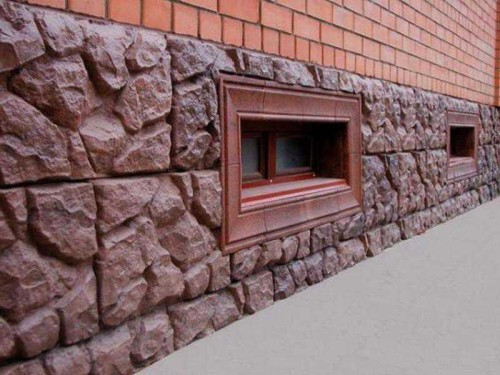

- Panels for facing foundations made of artificial stone, it seems to almost not distinguish from natural material. But work with such panels is much easier and easier than with real stone details. The process of cladding the base can even produce a non-professional, so there is no need to attract specialists for such a job and pay for their work. By the way, not only smooth, but also the angular elements are available on sale, so the trim of the corners of the base can be done with particular accuracy. Artificial stone, unlike natural, has a quite acceptable price.

Foundation Panels: Advantages and Application Scope

The most popular material for finishing the base is plastic panels for the foundation, since at a relatively low cost they have good quality and good specifications. It should be understood that the plastic panels for the foundation in their composition are noticeably different from similar materials used in the interior decoration of the walls and the external facing of the facades. Since the base of the building, and even on the foundation of the house of the panels, there are the greatest loads, the finishing material must be sufficiently strong and reliable.

The standard plastic panel is a three-layer part, in the center of which is the PVC sheet, protected on the sides of the durable plastic. PVC, besides, additionally attached to a metal cage, as a result, the panel for decoration is obtained tough, solid and strong. Such facing material has a number of positive qualities:

- The foundation panels are made of components that do not enter into chemical reactions with aggressive substances, therefore, it will be impossible to spoil such a cladding with acid, alkali or something else.

- The weight of the panels is relatively small if you compare them with other similar finishing materials, so the load on the base of the house will be insignificant. This is especially true for buildings collected from panels, because the foundation under the panel sandwich is most often done lightweight.

- The process of facing can be performed in a short time, without possessing extensive experience and construction skills.

- The foundation panels are not lit, so they are considered fireproof.

- Consistent temperature differences in such a material are also not scary, so regardless of the weather popsicles will serve you for long decades.

- The strength of plastic panels is so high that they serve as a kind of strengthening of the main foundation and take care of the load that the high mass of the house has.

- Even the most imperidal base will look neatly and stylish, if you bind it with plastic panels. Such a finishing material can hide various shortcomings and errors made in the construction of the foundation.

Decorative panels for the foundation of the house have a wide range of applications:

- The main area of \u200b\u200buse of such panels is the trim of the base, as well as the main walls of buildings.

- From such a material you can perform internal partitions in homes, apartments, offices and other buildings of the most detailed destination.

- The foundation panels are often used in the construction of garages, fences and arbors, helping to give such structures a beautiful natural look.

- You can be faced with such material external parts of homemade fireplaces.

- The foundation panels are performed and practical functions, insulation of the walls of buildings or protecting the sauna, bath and swimming pools.

Deposit the base plastic panels, you will not need to spend time on periodic painting or plastering this part of the house. The panels will serve you for many years, without losing strength and beauty.

Subtleties of using plastic panels

- The cladding of the base with plastic panels is carried out according to a predetermined cladder. It is desirable that the lamp is made of metal - so it will be the most durable.

- All inputs in the house through which communications are passing, you need to sealed well before the start of work.

- The insulation and waterproofing of the foundation should also take care in advance.

- Such material is not suitable for the ceiling or floor finish.

- The weather at which work will be carried out should be sufficiently dry and warm. It is not recommended to deal with the trim of the base in conditions of high humidity, heat or heavy cold. If the ambient temperature is below 0 ° C, it is categorically impossible to work with plastic siding.

- Plastic siding is not amenable to corrosion and rotting, which cannot be said about metal fasteners. To avoid problems in the future, when installing the material, use stainless items, for example, galvanized.

- On the walls with a large area, you need to finish the panels carefully and taking into account some nuances. When the ambient temperature changes, the decoration details slightly change the size that it may later be reflected in the appearance of the base. So that the panel lay smoothly and did not twist over time, the temperature seams should be made between them. They are narrow strips deposited between individual cladding sites and creating a stock of space in case of expansion and narrowing the material under the action of temperatures.

Foundation Finishing with decorative panels

Preparation of the founding of the house

Preparatory work before finishing is equally important than the process of facing. Before decommissioning the base with decorative panels, you need to do the following:

- Protect the foundation from dampness by performing its waterproofing. The base is coated with any hydrophobic material, starting from a height of 25-30 cm on the soil level. From how qualitatively the foundation will be protected from water and moisture, its reliability and service life directly depends.

- By doing the waterproofing of the base, you can not forget about its insulation. It is possible to insulate the foundation by foam, polypropylene or something like that. Sheets of heat-insulating material are attached to the wall, then covered with the reinforcing grid and are plastered. The insulation of the foundation is a pledge of a comfortable stay in the house.

- When the base is protected from moisture and is properly insulated, you can make a break. The scene is taken to pour under a slight inclination, the angle of which is 1º for every 10 cm of length. The length is calculated in such a way that the scene performed from under the edge of the roof by about 20 cm.

- Preparation of the foundation for facing work also involves removing the old coating and removing all contaminants with a rigid brush or broom.

Stages of finishing foundation with decorative panels

- Plastic panels are attached to a pre-created frame. This framework is made from metal or wood. Wood for the crate must be processed by special antiseptics and antipyren, which will protect it from flobs, mold, parasite lesions, and also reduce flammability. Wooden bars for the frame must be long, the width of the should be about 35 mm. The lamp is mounted on the foundation using a cement screed or screwed by a screwdriver.

- Finishing the corners of the structure can represent some difficulties, but if you purchase special corners in advance and secure them on the frame, the panels are docked in these places perfectly. Such plastic corners are easy to find on sale, they should be shortened to the desired indicators and fix on the crate with the help of a screwdriver.

- After creating a carcass, you need to wait a few days, after which you can start further work.

- Get on the construction market special moisture-resistant OSP plates and install it over the crate. If one stove size is not enough, use several elements by fixing them close to each other. Remember that there should be a gap of several centimeters between the level of the soil and the bottom fixed slab. After conducting a job, you protect the foundation from shrinkage and deformation. OSP plates are preferably mounted using selflessness.

- When the plates are installed, you can proceed directly to the process of cladding the base with plastic panels. Fix the elements of the finishing material is the easiest way with the help of screws.

- Starting work, move from left to right and the first panels are attached to the top of the foundation. The whole process must be performed consistently, otherwise the cladding will turn out to be a curve.

- During the installation of moisture-resistant plates, you can note those places where the frameworks are running. When you fix the plastic panels on the foundation, the screws are desirable to screw in at the level of these marks - so the details will stay the stronger.

- Plastic panels should lay down to each other tightly, without cracks and skips. A small gap should only be near the surface of the soil.

- In the process of facing the foundation, plastic panels can be resorted to the help of materials such as starting and finishing profiles. These items will make the installation process easier and fast, and the panels themselves will be very firmly and securely fastened. Hurt a similar cladding or remove individual details from it it will be impossible.

- On this, the finishing of the foundation is completed with plastic panels.