What is better - wooden lining or plastic Building materials

What is the lining better - wooden or plastic? This question cannot be given a definite answer - it all depends on the purpose of the room, for the finishing of which the lining is used. Cheaper - not always better, and durability depends on the operating conditions.

Content

Each type of lining has its drawbacks and its advantages. To determine which lining is more profitable for finishing a certain room, you should compare the qualities of the lining according to certain parameters.

Comparative characteristics of plastic and wooden lining

Price

Artificial materials are cheaper than natural. The price of plastic lining is several times lower than the wooden. Price Wooden lining depends on the two positions:

The cheapest wooden lining of the Pine Class "B" will cost you at least 180 rubles per m². For plastic lining, you pay 120-150 rubles per square. It is beneficial obvious. The question is whether the plastic lining is suitable for finishing a particular room, and how much it will last.

Durability and moisture resistance

The service life of any material depends on the conditions of its operation. Atmospheric conditions, air humidity and temperature differences are affected on the durability of the lining. Air humidity in turn depends on the operation of the ventilation systems.

Plastic moisture lining is not afraid. It suffers more from high and low temperatures and from their sharp drop.

Wooden lining hygroscopic. The ability to absorb moisture depends on wood - dense wood rocks have low water absorption, soft wood absorbs moisture well. With insufficient ventilation, wood will not dry and starts rot. At low temperatures, wet wood is destroyed.

Despite the durability during operation in wet conditions, plastic trigs will not suit for bani finishes.

For external work there is a special lining capable of withstanding high and low temperatures. This is rather a variety of plastic panels, or siding, which manufacturers are often issued for the lining. In fact, the lining is called a panel of about 10 cm wide.

Thermal conductivity

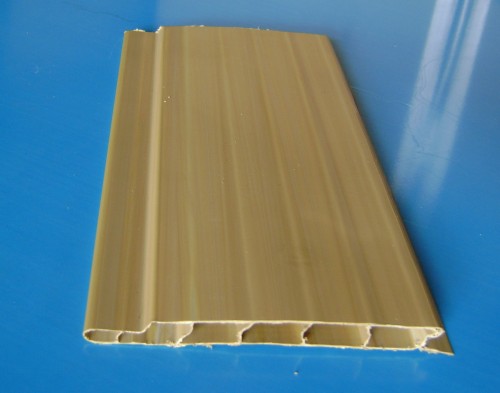

Plastic lining has lower thermal conductivity compared to wood due to the inner cellular structure.

From wooden lining the lowest thermal conductivity of Abashi. Wood coniferous rocks has the highest thermal conductivity. At high temperatures, it is strongly heated and highlights the resin.

Soundproofing

Compared to wooden, plastic lining is better than the sounds. But both types of lining do not provide sufficient sound insulation.

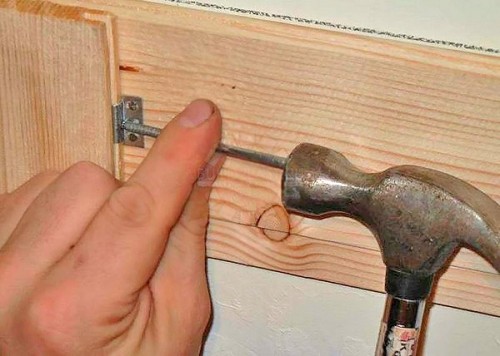

Any lining attached to a wooden crate, and there is always the ability to pave a sound insulation materials between the main surface and the lining. For this reason, the soundproofing properties of the lining are not important.

Easy installation and weight

Installation of lining does not represent complexity and does not require preliminary surface preparation. The principle of installation of plastic and wooden lining does not have large differences.

By weight, plastic lining is much easier wooden. When installing plastic, an additional load on the wall is not created.

Colors

Plastic lining allows you to choose any color. It can imitate the various breeds of wood, or have rich colors.

The tree is beautiful with its structure and always pleasant to the eye than a piece of plastic.

Resistance to mechanical damage

The tree is stronger compared to plastic. Plastic lining has a thin coating and does not withstand strong blows. The tree is able to withstand large mechanical loads.

Fire resistance

The tree well supports burning. To increase fire resistance wooden lining, special impregnations are used.

Plastic lining does not support combustion, but at high temperatures begins to melt and distinguishes substances dangerous to health.

Care and preparation for work

Wood requires processing to protect against rotting, pests and high humidity. Over time, it loses its original color and contaminated.

Plastic is afraid of sun rays, over time it can change color. Pollution is not absorbed into the surface of the material and are easily removed from the plastic surface with the help of detergents.

Plastic Walking Scope

Plastic lining is used to finish the corridor, ceilings, loggias, veranda, toilets and bathrooms. In wet rooms, the walls should be pre-treated with antifungal primer to prevent the appearance of mold.

To finish the bath plastic lining, it is allowed to use in the rest room and in the washing room in order to save money. It is preferable to finish a bath to use natural materials.

You can buy plastic lining in any building materials store. Planks have a length of 2.7 or 3 m. Before buying, calculate the lining of what kind of size it is more profitable to buy, so that there are less waste.

Where wooden lining is used

Wooden lining for the trim bath is the most suitable material. For the finishing of pair other options does not exist. Here the question is resting only in the species of wood, from which the lining is made.

Wooden lining is popular for finishing private houses - mansard, veranda, kitchen and corridor. The warm tree view always gives the comfort of a country house.