Foam glass: characteristics and application Building materials

The foam glass is the newest thermal insulation material of universal use with unique advantages.

Due to the almost zero thermal conductivity coefficient, as well as a wide range of applications, is one of the best insulation for walls, gender and roofs.

Content

Benefits of material

The characteristic properties of the material are:

- resistance to different temperature modes, oxidation and erosion;

- resistance to aggressive chemical media;

- excellent properties of thermal insulation;

- hygienic and environmental safety;

- durability;

- not susceptible to burning, waterproof, not toxic;

- convenience in machining, well sufficiently bonding;

- the ability to maintain its characteristics stable (not subject to shrinkage and deformation).

In general, foam glass is an excellent thermal insulation material of a wide range of use. Its warranty period of operation as a heater is measured by many decades - over the years there are no significant changes in the structure and characteristics of the foam glass (while maintaining the physical integrity of the material). The use of foam glass will increase the reliability of structures. It should be noted the same way that its use is possible in cases where the use of other materials is difficult and inffective.

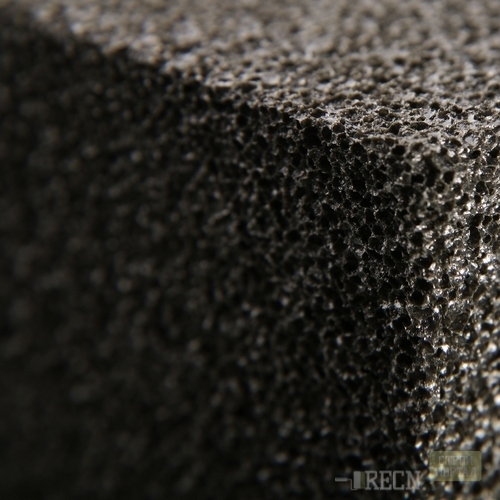

Production technology

Penodoneglo produced in an industrial method according to standards. For the production of this thermal insulator, the waste of glass production is used - either the same materials as in the production of ordinary glass (quartz sand, soda, limestone). Grinding silicate glass is saturated with carbon (with the addition of coke, dolomite, chalk, anthracite, etc.), so that by heating to the furnace to the temperature of the order of 900 ° C to flash, and after slow cooling (annealing), get a solid cellular glassass chamber. Cells of foam glass closed, round or hexagonal shape. Their sizes can vary from the fraction of a millimeter to a centimeter. The porosity of the resulting material ranges from 80 to 90%. Due to gas formation and foaming, the volume of glass increases fifteen times.

Produced Penycle Types

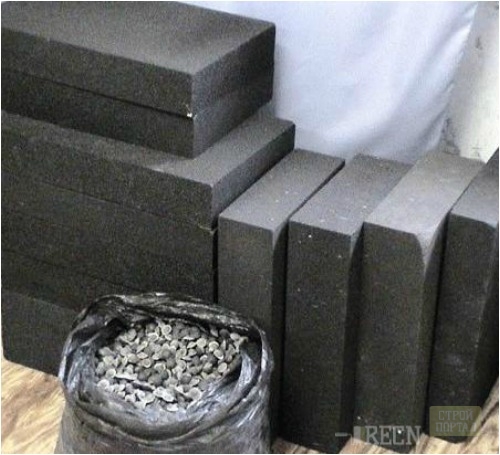

Distinguish the following types of foam glass:

- block (blocks, plates);

- granulated foamworm - crumbly insulation:

- molded insulation (shaped products - couplings, fittings, arched insulation, etc.);

- crumb or foam glass fight.

Blocks (plates) of foam glass are used in any kind of construction, in combination with the most different materials. In the process of mechanical filing blocks, waste in the form of crumbs of foam glass is obtained. Granulated foam cell is produced accordingly in granules of various diameters - from the minimum possible (millimeter shares in diameter) to several centimeters.

Characteristics of foam glass

The following characteristics are inherent in this material:

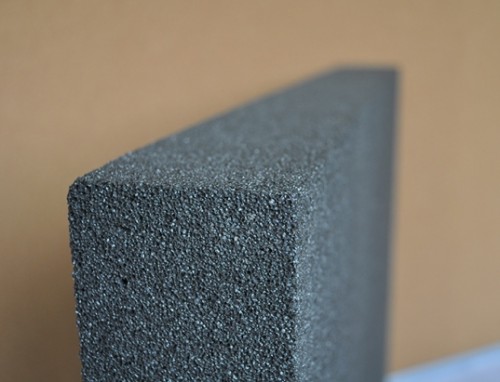

- High strength in combination with very low thermal conductivity of foam glass. This material is almost defable to begib and compression.

- The stability of parameters - foamglass practically does not give a shrinkage and retains stable dimensions, as well as physical parameters (strength, thermal conductivity, water absorption capacity), therefore, over time, building structures using foam glass blocks do not change their geometric sizes under the influence of operational load.

- Withstands various temperature modes (from -200 to +400 ° C).

- Noise absorption, hydro and vaporizolation. Penodially absolutely waterproof.

- Perfectly mechanically processing and gluing. With the help of a joinery tool, you can easily give foamula any dimensions and shape. The foam glass is perfectly glued (by any building mixture, bitumen or glue), and mounted with any fasteners.

- Durable, chemically resistant material, not toxic. Resistant to rodent teeth. Insects, fungi, mold do not become in the penny. Differs in sanitary and environmental safety.

The disadvantages of foam glass include:

- some fragility on a spill during installation work;

- its high cost compared to the rest of the heater.

Scope of foam glass

The service life of the insulation of the foam glass is at least 100 years. Penodoneglo - excellent insulating material in individual construction. With it, you can independently insulate any building, including objects with specific requirements for temperatures, humidity modes (for example, saunas, pools, baths, hozblocks, basements, and chimneys and fireplaces).

The blocks of foam glass and foam glass plates are used to insulate the building structures of any shape, are used in building areas with different climates, as well as during the reconstruction of buildings.

The granular foam glass is characterized by a lower price compared with blocks, as well as somewhat inferior to them in thermal insulation properties. Granules are successfully used as heat-insulating backfills - for insulation of gender, roof, outer walls, as well as aggregate for the preparation of masonry and plaster solutions, as a component of light concrete.

The foam glass crumb is successfully used as a bulk thermal insulation material, which has many properties of foam glass, as a complete replacement of clay and similar materials.

Due to its chemical and thermal stability, foam glass can also be used to isolate equipment and reaction media.

Where to buy foamglo

Penodoneglo is a relatively new insulation in the modern building materials market. Despite the wide selection of thermal insulation materials, it is not easy to find a product that meets all the requirements at once. The foam glass "ETIA" (the product of Russian production, produces the same name "ETIA") - is known for its qualitative characteristics of a unique material for thermal insulation. For more than 70 years in a row is produced by foam glass Foamglass (Pittsburg Corning Corporation - America, Pennsylvania) - meets the highest quality standards.

New comments

Add a comment

To send a comment you need authorize.

For Pinosklo bath - just an excellent option. It is at least excellent thermal insulation and fire safety guaranteed.