Recessable with your own hands Climate

Well, when pure frosty air enters the room, it is a pity that the same portion of warm air will volatile through ventilation. It is able to correct the position of the air recovery. The recuperator can be bought, but if there is a desire, it is better to make it with your own hands. This will be discussed below.

Content

What principle the recuperator

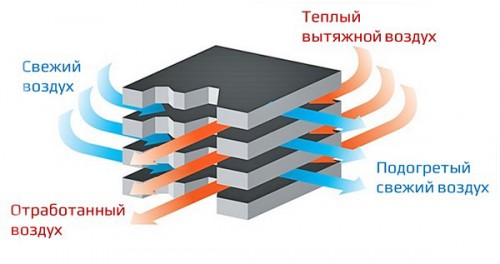

The principle of operation of the recovery of any type is to exchange air flow by heat, i.e. In winter, a higher temperature from exhaust air is transferred to the incoming outside, and in the summer, on the contrary. All this happens inside the aggregate.

Thus, the recuperator:

- Air ventirs, but the room temperature does not decrease and is supported at one level.

- It saves heat in the cold time, and in the roast is a reliable barrier from entering the premises of hot air from the street.

- Save energy resources.

Simplified principle of operation of the recovery can be described as follows:

- air from the room moves along the square pipe;

- air incoming moving in the transverse direction;

- cold and warm streams are not mixed, because They are separated by special plates.

Explains the principle of operation of the recovery video:

Types of recuperators

The following types of these aggregates are popular:

- Lamellar. The design consists of plates combined into a cube. Air flows both deleted and trimmed, pass through the channels towards each other, intersect, exchange temperatures, but do not mix. This device is characterized by simplicity and compactness.

- Rotor. It requires a source of electricity. Inside the cylinder is a rotary element, which is continuously rotating between the channels, by which air flows and removes. At the same time, one side is in contact with air entering outside, and the other with what is entered into the room. Thus, air flows are interchangeed. This unit is large enough, therefore used mainly in industrial premises. KPD he has high - can reach 87%.

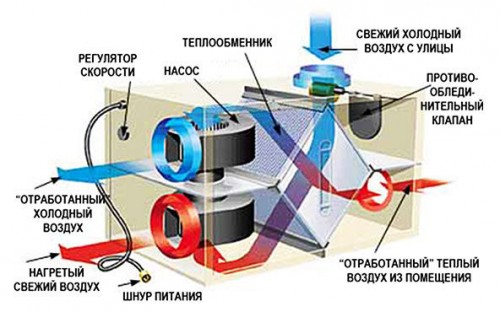

- Water recycling. In efficiency, it is the same as the heat recuperator, but the design of it is more complicated. The main difference is that its individual parts can be located in different places. An element transmitting heat here is either water, or antifreeze. The circulation of the coolant is carried out forcibly and is not possible without a power source.

- Root. This type of recovery is industrial. CPD - from 55 to 68%. Its installation and maintenance do not require extensive costs.

The simplest and inexpensive, among the above, is a plate heat recovery. Therefore, it is easiest to make such a recuperator with your own hands.

Recessable with your own hands

Pros and cons of the lamellar recovery

There is no perfect equipment by 100%. This also applies to the air recuperator with a lamellar. So, positive parties:

- high efficiency - from 40 to 65%;

- easy design - there are no rubbing and moving parts, which excludes frequent outputs with the system;

- low operating costs - electricity does not consume.

From the negative it should be noted:

- No wagon exchange function. Only heat exchange is possible.

- Frost in winter time. To exclude this phenomenon, the recuperator is periodically disconnected or supplied with its special valve - bypass.

- The presence in the design of the recovery of crossed pipes, which is impossible to circumvent, but not so easy to implement.

Materials for the manufacture of homemade heat recuperator

To embody the idea of \u200b\u200blife, the following will be required:

- galvanized roofing iron - 4 square meters. or sheet aluminum, copper, textolite, getinax;

- tECHNICAL CONNECTION 0.2 cm thick for laying between plates or rack wooden polenal;

- neutral silicone sealant;

- box for hull. Take ready-made tin or manufactured from MDF, plywood or metal;

- plastic flanges in size corresponding to the diameter of air duct pipes - 4 pcs.;

- pressure drop sensor;

- mineral wool;

- corner for racks;

- hardware;

- electrolzik.

We make heat recovery

By purchasing the necessary materials, proceed to the manufacture of the recuperator:

- Unlock material and cut square plates. Part size from 20 to 30 cm. It will be blanks for cassettes. They will need 70 pieces. It is best to fold the material into several layers and cut the blanks with electric bubbles, then they will turn out to be smooth. The ideal evenness of the blanks is a prerequisite.

- Cut the rails or a plug in the size of the sides of the square, and glue this plastle on opposite edges of all billets other than the last one. We wait until the glue is dry.

- We smear the top of the rail or plug and collect the squares in the cassette. By placing each subsequent sheet, turn it on 90 degrees in relation to the previous one. It turns out that the channels occupy a perpendicular position relative to each other. The latter will be the plate on which we did not stick anything.

- We are tightened by the future heat exchanger framework using for this corner.

- Fill the gaps prepared earlier with sealant. Acid sealants do not fit, because They will cause corrosion of metal plates.

- We perform fastenings for flange connections on the walls of the cassette. We do the drainage hole at the bottom of the cassette, where we insert the tube to remove the condensate.

- On the walls of the case we make guides from the corner. Cassette can be removed for prevention.

- We insert the cassette into the housing, the height and length of which are equal to the diagonal of the square. In width, it is the same as a set of plates.

- Fix 40 mm layer of mineral wool inside the housing on the walls.

- To resolve the issue of deleting toes, it is necessary to insert into the part where the warm air passes the pressure sensor. As soon as the temperature outside will reach 10 degrees, the frost of the recovery body will begin. Pressures will increase and air from the street will go through Baipas.

- We introduce a ready-made recuperator into the ventilation system.

Usually, such a self-made recuperator has 65% of the efficiency, therefore is capable of maintaining a comfortable microclimate in the room.

Note: One cassette in the case is not the norm, there may be 2 or more to increase the efficiency, but their dimensions are necessarily the same.

Calculation of the recuperator

The magnitude of thermal energy transmitted between the plates is found according to the formula:

20 W ∙ x s ∙ dt. where S is the plate area in square. m.

To calculate the capacity of the recuperator sufficient to heat the air, we use the formula:

p (W) \u003d 0.36 ∙ q (m3 / sec.) ∙ DT.

Here:

- Q denotes energy spent on heating / air cooling and equals: 0.335 x L x (t Kon - T NCH). Other characters:

- air flow cube. m per hour - L. norms provide that 1 person requires air intake from outside 60 m3 / h;

- initial temperature - T NCH;

- the temperature obtained as a result of the heating exchange - T con.

2. DT - temperature.

In conclusion, see the video on the manufacturer's manufacturer:

New comments

Add a comment

To send a comment you need authorize.

What are you carrying? Fresh air from the street is served through the silencer .... The silencers are installed between the ventilation unit and the network of air ducts laid by the premises, regardless of the supply, this branch or exhaust, in order to reduce the noise caused by the fan operation in the rooms where the air is satisfied, and where the air is satisfied, so you go, then you will correct the shoals for such dolborators and dolborators, instructions BL @ Read at least not fate before it is a bullshit on video to record?! People, contact professionals in the field of ventilation, for the alteration of "Creations" here are such a Mount Mount Specialists overpare!