Cellular polycarbonate, material features Building materials

A few years ago it was impossible to imagine a greenhouse building without the use of glass. Strawy, practical and reliable glass materials for many years in a row remained the best option for trimming greenhouses. However, modern technologies brought a new trend on the building materials market, and a cellular polycarbonate for greenhouse became an alternative.

Content

This upgraded material is used in a variety of designs and floors, providing high weather resistance.

What is a cellular polycarbonate?

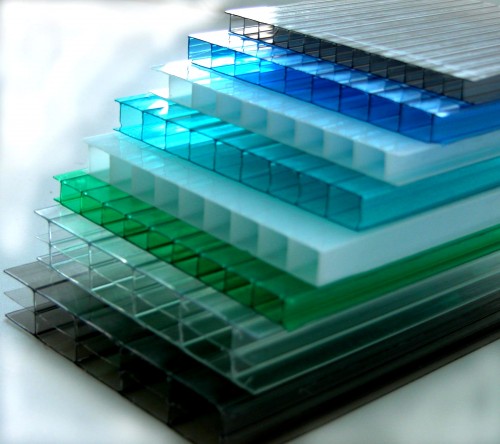

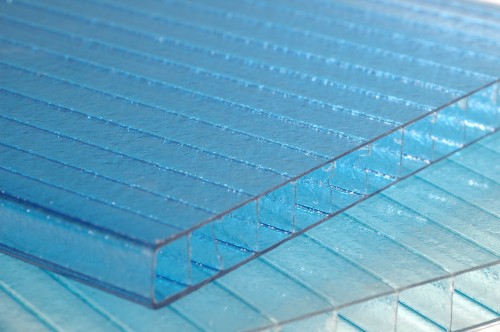

In modern construction technologies, a sheet of polycarbonate cellular is often used quite often. – polymeric material with a unique structure in the form of cellular cavities. It consists of several plates located in parallel to each other, which are attached to each other with special ribs in the form of jumpers. Such a design provides extraordinary strength, and, the greater the number of edges are provided in a polycarbonate segment, the higher its reliability.

This innovation has already firmly occupied positions in the field of arrangement of all sorts of canopies, greenhouse structures, arbors. Cellular polycarbonate, the price for which is quite accessible, has a lot of variations for use, due to which the material is manufactured in various sizes: the length of the sheets can reach 12 m, and the width is up to 32 mm.

Among the most common manufacturers and trademarks on the cellular polycarbonate segment are such:

- Poligal;

- Novatro;

- Polynex;

- VIZOR;

- Polyside;

- EUROLUX;

- Makrolon;

- Plastilux;

- Marlon;

- Makrolux;

- Haigao.

Features of cellular polycarbonate

Considering the properties with which the cellular polycarbonate, characteristics and key features can be distinguished by the following aspects:

- material has extremely high strength and wear resistance - a sheet of cellular polycarbonate is 8 times more reliable than the acrylic panel, as well as 200 times more stronger than glass;

- cellular polycarbonate also has a high operating rate, due to which the two-layer sheet skips up to 80% of light;

- panels are characterized by impact resistance, durability, resistance to temperature effects and reliability;

- sheets of this type of polycarbonate have high traffic permeability, as they can pass up to 90% of sun rays;

- due to the presence in the structure of the air layer, the polycarbonate has good thermal insulation indicators, and this reduces the cost of heating the room;

- the material has a high degree of thermal conductivity, due to which is actively used in the greenhouse;

- cell sheets have good sound insulation, because they can reduce the noise level by 18-24 dB;

- well protect the room from hail, careless circulation, accidentally fallen objects and acts of vandalism;

- cellular polycarbonate is also low weight: in comparison with the glass panel weigh 10-15 times smaller, and with acrylic - 3 times;

- despite high light transformation, such sheets detain ultraviolet radiation;

- fire safety - due to the addition of substances of "anti-epires", the material slowly flashes and highlights very few poisonous gases; The minimum temperature for ignition is 570 ° C, and under open fire, polycarbonate melts, turning into harmless flakes;

- polycarbonate panels are easy to molding, for which preliminary preparation will not need.

Sensitivity of the material.

This material is strong enough and durable. However, before the polycarbonate cellular to buy , it is necessary to know that it can show sensitivity to such chemical compounds as:

- salts solutions;

- organic acids;

- mixes of various fats;

- ammonia in gaseous and liquid state;

- various amino acids;

- mineral acids at any concentration;

- solvents;

- dyes.

The degree of exposure to deformities and structural changes under the action of these substances will depend on the concentration, the duration of contact with polycarbonate, pressure, temperature and stresses in the panel. In any case, it is desirable to avoid chemical processing of the surface of a cellular carbonate.

Aspects of cellular polycarbonate

When choosing a material, a number of requirements and basic characteristics should be taken into account, but they all depend on the purpose of the future buildings. The most common scope of the use of cellular polycarbonate is greenhouse facilities. Consider the most important points that need to be taken into account when choosing raw materials:

- Initially, it is necessary to determine the values \u200b\u200bof the panels, because the cellular polycarbonate in size is sufficiently variable: 2x2.1 m, 6x2.1 m, 12x2.1 m, etc.

- At the same time, pick the sheet thickness, since this indicator affects the strength of the structure. For showcases or shields, a sheet of 4 mm thick, for visors and greenhouses - 6 mm, for roofs, partitions and arbors - 8 mm, for walls and vertical surfaces - 10 mm.

- Cells should be directed along the longitudinal part of the sheet, however, some manufacturers admit the "wave" cells.

- The color of the polycarbonate panel can be in such variations: opal, blue, yellow, bronze, red, green and transparent.

- Choosing a cellular polycarbonate, reviews about which are made up by specialists, consider that high-quality materials should have a special film that protects against the penetration of UV rays.

Features of using material

When working with this material, there are some specific features, which will make it possible to simplify the construction process and avoid unpleasant errors. Consider the most important aspects:

- Regardless of whether you chose a cellular polycarbonate color or transparent, it will have equivalent lighting indicators. Therefore, during the construction of the greenhouse there is no need to record the parties of the light, refractive angles, etc. The material simply covers the design and is ready to use.

- Due to the high thermal insulation coefficient, it is possible to mount not only the roofs from the polycarbonate, but also to be lined with a whole greenhouse, fixing it to the carrying frame of the structure.

- The thickness of the panels affects the performance characteristics: the thinner of the sheet, the easier it is to form it, and the thicker it is more reliable. Try to find an optimal consensus.

- Cellular polycarbonate is not static material that changes its dimensions when cooled and heated. If not to take into account this feature, even small discrepancies can lead to unpleasant consequences. To extend the service life of the polycarbonate, it is necessary to calculate the thermal expansion coefficient. Its indicator suggests that when the temperature changes, only 1 ° C, the material can change the size of 0.065 mm in each routine meter. Therefore, when installing panels, it is necessary to leave the gaps of 2 mm that will not allow the polycarbonate sheet to fall out of the grooves when decreasing.

Features of the choice of material for the greenhouse structure are shown in the video: