Dry waterproofing. Features of dry waterproofing mixtures Insulation

The waterproofing gasket is an integral stage of work in the construction of any building. The durability of the construction and comfortable operational conditions will depend on the quality of the waterproofing material. But how among the manifold of building materials in the market to choose a suitable for a particular case? Professionals have always preferred dry waterproofing - the abundance of varieties allows you to choose an option for any needs. In this article we will tell you what waterproofing mixtures to buy for the construction of a reliable and durable house.

Content

General characteristics

The main advantage of all dry mixtures, be it cement waterproofing or rolled material is compatible with almost all surfaces. Most of them are durable, durable and do not pose a danger to human health and the environment.

The price of the waterproofing mixture is determined by its composition and, accordingly, the appointment. A wide variety of combinations of fillers and additives makes it possible to choose the best option for any purpose, whether it is the construction of a country house or pool.

The main advantage of dry waterproofing is that it is extremely easy to use and does not require special equipment or skills (with the exception of rolled materials, which we will tell a little lower). This is usually a dry powder material that is sold in packages. It is diluted with water, stirred and applied to the surface.

Composition

Regardless of the type and components, all dry waterproofing mixtures consist of three ingredients:

- Binder (cement, resin, etc.).

- Fillers (mica, perlite, quartz, pigments).

- Chemical additives (plasticizers, polymers, frosted accelerators, water-repellent substances, etc.).

A relatively low cost of dry waterproofing is explained by a rather simple manufacturer technology - the components are divided into suitable fraction size, dried, dosed and mixed in the proportions, after which they are packaged in packets of various volumes.

Depending on the size of the fractions of the filler, dry mixtures are divided into the following types:

- Concrete - fractions are more than 5 mm. The compositions where the cement-sand mixture acts as a binder. Depending on the additives present, I can possess various qualities - high strength, good adhesion to any surfaces, waterproof, etc.

Concrete dry waterproofing can crack when drying, which is its main disadvantage. For this reason, it is recommended to use only to protect tough structures. Cement formulations are distinguished by vapor permeability, so they can be used under conditions of negative water pressure, for example, for the internal processing of the foundation.

Concrete waterproofing increases hydrophobic design qualities due to their own waterproof. The higher the cement brand used in the mixture, the better its quality. In the domestic market is very popular with waterproofing Cerezite.

- Mass - fractions are less than 5 mm. The mixture, which contains minerals, quartz sand and polymer additives. Due to the active chemical composition, it can deeply penetrate the surface of concrete and bricks, fix it and not only ensure reliable waterproofing, but also to strengthen the material itself. Penetrating the walls and frozen, the mixture forms insoluble water crystals that clog all free emptiness and pores inside. At the same time, waterproofing does not violate vapor permeability, retains ductility and mobility, so it can be used to treat horizontal, vertical and even ceiling structures - it will not be stroke. The mixtures are distinguished by frost resistance and are suitable for the insulation of the foundations to the depth of the ground freezing.

- Dispersed - mixtures with very small fractions up to 0.63 mm. As a rule, supplied in the form of pasty mastic, and not dry powder. Used mainly to process premises with high levels of humidity before facing the cafeter (kitchens, bathrooms, showers, pools). Mastics are able to close even the smallest cracks up to 2 mm and can be used in conjunction with silicone to protect warm floors or walls.

Views

There are two types of waterproofing: primary and secondary. The primary use special fencing reinforced concrete or concrete structures of increased waterproof. They are treated with mortar mixtures, which are hermetically clocked the seams. Secondary waterproofing is materials of various groups whose action is aimed at protecting structural elements.

Types of dry waterproofing:

- penetrating;

- plaster;

- coating;

- bedmark.

Each of the species is characterized by applying and specific use. Consider in more detail each of them.

Penetrating

At the heart of penetrating dry waterproofing lie cement mixtures, aggregates and chemical additives, selected according to the appointment. Since concrete is distinguished by a porous structure, chemical additives dissolved in water, does not interfere with penetrating inside and join the reaction with concrete components. As a result, insoluble crystalline compounds scattered in chaotic order are formed. They become part of the design itself, thereby increasing its strength and hydrophobicity.

In the absence of water, the growth of crystals inside the concrete slab can slow down or stop at all, so after applying it follows some time to protect the surface from excessive evaporation of moisture (covering the film). In order for the penetrating waterproofing to fulfill its purpose to fully and in the most deeply penetrated the concrete, it is required to wait until 24 hours.

Depending on the composition and activity of chemical additives, waterproofing can penetrate to a depth of several tens of centimeters. The deeper the penetration, the better the waterproofing.

Such formulations are not used to treat surfaces with high density, for example, asbestos cement, pressed structures, etc.

There are two varieties of dry penetrating waterproofing:

- Capillary - consists of portland cement, chemical additives and fillers. Used to protect porous materials.

- Injection - point surface treatment to restore the waterproofing layer. Suitable for the repair of facades, foundations, dry waterproofing floor.

The main disadvantage of penetrating waterproofing consists in high cost compared to bituminous rolled materials. But even the highest price is very quickly compensated by further expenditures for operational needs and repair work. Unlike the aforementioned rolled insulation, the penetrating mixtures will protect concrete walls and the foundation from moisture during the entire service life of concrete, without needing to be repaired. In addition, the cost of penetrating waterproofing is caused by the simplicity of its application - it does not require careful preparation and leveling of the surface, as in the case of the ruberoid.

The advantages of penetrating dry waterproofing:

- durability (serves exactly as much as the concrete surface that it protects);

- stable design tightness even with constant strong water pressure;

- self-deficiting in the case of cracking or pores;

- resistance to temperature drop;

- simplicity of application (does not require the preparation of the foundation);

- wear resistance;

- you can handle the designs of any shapes and sizes;

- suitable for outdoor and internal works;

- the possibility of using drinking water reservoirs (non-toxicity, direct contact with moisture).

Plaster

Plaster isolation, in contrast to the previous species, is superficial. The basis is the cement binder, a variety of chemical additives and small quartz sand. The advantage of such mixtures is that they can be used to protect the foundations, underground parking, basements and other structures both from the inside and outside.

Plastering waterproofing is applied into one layer and are often used to level the surface. In order to extend the timing of the waterproofing layer, you can simultaneously use other types of waterproofing, for example, suture or penetrating, as well as strengthen the wall with a reinforcing grid.

You can apply the plaster mixture on a steady base that will not be subjected to progress. This is the main disadvantage of this material. In addition to non-viability, professionals are unhappy and the fact that the surface before applying should be carefully processed - to clean, align, primed. Otherwise, the waterproofing solution will last long. Difficulties also occur when processing surfaces of complex structures.

However, the plaster dry waterproofing is not for these qualities:

- it provides reliable tightness of the processed structure, even with strong hydrostatic pressure;

- it is enough to apply one layer of several millimeters to protect the surface from moisture (efficiency);

- withstand sharp temperature differences;

- resistant to mechanical wear;

- equally well protects the design both with external and internal processing (it is possible to make waterproofing foundations from the inside);

- durability (subject to the technique of application and absence of deformation of structures);

- the mixtures are completely non-toxic - they are suitable for protection against leaks of drinking water tanks;

- plastering mixtures can also be used for waterproofing, and to align the surface before finishing;

- after hardening the composition, it is possible to apply decorative finishing materials (tiles, mosaic, paint, etc.).

Refractory

The coating waterproofing is made on the basis of bitumen, polymer or mixed varnishes, mastic and paints with the addition of dry cement mixtures, fillers and chemical additives. It can be applied in cold or hot (molten) form in 2-3 layers. A dry mixture of waterproofing is used for anti-corrosion protection of structures, for example, during the construction of foundations, underground tunnels or other beaten structures. At the same time, the composition is applied by the exposure of moisture, that is, outside. Cement-based coems \u200b\u200bcan be applied on both sides of the design.

The waterproofing composition after frozen is forms a waterproof plastic coating with a thickness of 1-3 mm. Elasticity is explained by the presence of polymers and plasticizers. At the same time, the cooler waterproofing can be applied to materials with any porosity - it will protect the surface from moisture and practically will not affect the mass of the structure.

There are several types of loose dry waterproofing:

- elastic;

- semi-plastic;

- hard.

The most important disadvantage of bituminous waterproofing is its briefness. Compared to other mixtures, it serves the least, but in some cases it is better to choose it, especially since the product price is very low. For example, if you need to handle a garage or a guest house.

It is also possible to note the fact that before applying the coating waterproofing, it is required to prepare the surface, and then ensure the protection of the frozen composition from mechanical damage.

The advantages of this type of waterproofing are a bit:

- low cost;

- can be applied on the design of any complexity;

- easy to use.

Bedmark

The purpose of laying waterproofing materials (mixtures) is the sealing of underground structures, foundations and walls of structures. There are additives in the composition, which at moisturizes begin to actively swell. When the mixture is placed in a crack or gap between the plates, it expands and forms a dense waterproof barrier. The most simple and, probably, the first basic waterproofing was invented even in the Middle Ages and was widely used until the end of the 19th century. She was called the "clay castle" and was a well-thought-out system for protecting structures using natural materials.

It is resorted to the use of Bedmark mixtures for waterproofing when it is necessary to protect uneven or roughly treated surfaces, for example, a boob masonry or a strongly destroyed brick wall.

Occake

Okleechnaya dry waterproofing is a film materials are supplied in rolls and are bonded or fused to the surface. The most simple, affordable and, unfortunately, short-lived option is the roofing material. There are also more modern and high-quality examples: Izoplast, Ecoflex, izoelast, etc. In contrast to the roofing material they have multiple layers and contain fiberglass and polyester..

Despite the complexity of the installation and the need for special equipment, lining hydraulic seals gives good results.

For example, to make a dry floor or roof waterproofing, you should:

- Carefully prepare a treated surface smoothing unevenness (unevenness maximum permitted to 2 mm).

- Clean the surface from dirt and dust.

- Process the bitumen base primer for better adhesion with the web material.

- Stick blade.

The use of self-adhesive roll is a more economical option - you only need to cut and paste material. In the case of fusing waterproofing have to learn how to use a gas burner and attract mates.

But the roll materials can be used to protect not every design. So, they need to be protected from mechanical damage, can be laid on a level and, importantly, level surface.

Nice thing is that the relative cheapness of such waterproofing will last you for about 20 years and can be placed even on the structure with the possibility of deformation.

Disadvantages of dry lining hydraulic seals:

- it requires surface preparation;

- it can not be placed directly on the ground;

- for additional protection against damage;

- stacking in multiple layers;

- it applied only to horizontal surfaces (sticking to the wall very hard);

- can not tolerate high temperatures (requires compliance with fire).

waterproofing Technology

To provide high reliability against moisture based on the dry mixes must adhere to the following principles:

- Duplication - do not let the appearance through defects in coating. For this use several layers of waterproofing mixtures of different types, e.g., combining the injection and plaster, penetrating and obmazochnuyu etc.

- Create such conditions that the waterproofing perform only one function - to protect the structure from moisture. That is, its use as a finish coating or for leveling the surface is undesirable.

- The waterproofing composition and the base should be compatible in terms of physical characteristics at temperature effects or deformation to ensure reliable contact between the surfaces.

Preparation of the basis

Most types of dry blends requires waterproofing the preparation base for enhancing the adhesive characteristics.

Features of surface preparation:

- First, it is necessary to remove the old coating, if any - varnish, paint, wallpaper, tile, etc.

- Clean the surface and remove all irregularities. If required, perform a screed from the cement-sand mortar or gypsum.

- Treat the primer selected in accordance with the waterproofing used.

- When working with porous surfaces requires pre-moisturizing with a sponge or sponge. Thus, you prevent too fast evaporation of moisture when the waterproofing solution is drying.

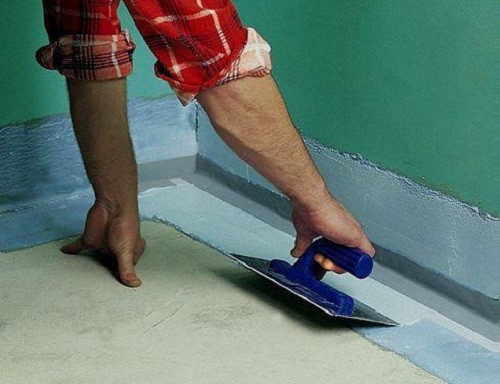

- On conditionally movable joints, i.e. there where joined vertical and horizontal surfaces should be arranged sizing elastic reinforcing tape and apply waterproofing over it.

- When working with waterproofing compositions, the humidity of the base should not exceed 4%.

- To complete shrinkage processes and reduce the risk of cracking, it is necessary to withstand the waterproofing layer after applying for several days. So, for compounds on a cement basis, this period is 25-30 days.

Looking at this list of requirements, it becomes obvious why the penetrating waterproofing is so popular - the base training phase can be completely omitted.

Preparation of mixes

In finished form, we produce only coating waterproofing masts, the remaining types must be kneaded alone. The accuracy of the compliance with the technology of preparation of the mixture depends its quality and durability.

Each part has its own cooking and usage instruction, but there are some general rules that apply to each of the mixtures:

- First, in the plastic container, where the solution will prepare, fall asleep dry mixture and only then the water is added, intensively stirring with hands or a construction mixer.

- The mass should be as homogeneous without lumps.

- After cooking, the solution should be given for some time (usually 3-5 minutes).

- Work with the best solutions at a room temperature between + 15C to + 23C.

- It is desirable to apply the solution as quickly as possible, while mixing periodically so that it does not lose the consistency. On average, his life "life" is 40-60 min, depending on the chemical additives.

- In the preparation of the new portion of the solution should be carefully washed from the previous container residues. If you breed a new mixture, when the pieces remained uncoupled in everywhere, as a result, it will be unsuitable for use and short-lived insulating material.

Application of waterproofing

In this section, we will briefly describe the specifics of the application of various types of dry waterproofing mixtures and materials.

How to lay rolled waterproofing:

- Prepare the basis (align, clean from dust).

- Unroll a roll, warming up his torch and pasting to the surface.

- To adjust the rolls of the brand 15-20 cm each other and the same - on the walls.

In more detail about the technology of laying rolled materials for waterproofing, you can read in articles "Roofing regulatory: characteristics, brands, properties" and "Bikrost: characteristic and technology of laying".

How to apply coating waterproofing:

- Work with lubricative compositions may be at a temperature higher than + 15C and at a humidity of not more than 60%. Such conditions should be supported until the waterproofing is completely drying.

- For applying a solution, spatulas, wide construction brushes or rollers use.

- Drying time directly depends on the thickness of the applied layer, temperature and humidity in the room.

- It is possible to apply the next coating or finishing finish on waterproofing only after drying it.

Read more about how to apply penetrating waterproofing, read in the article "Penetrating waterproofing: characteristics and technology of protection of basements".