Dry mixes for plaster walls Walls,Building materials

How to choose a mixture for plaster walls

A dry mix for plastering walls in bags of packing 25-30 kg, as shown in the photo.

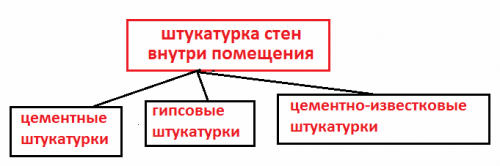

What are dry mixes for plaster walls

Depending on the fillers, plaster mixes are produced

- cement

- cement-lime

- gypsum

Cement plaster

The main components are cement - as an astringent and sand - like a filler.

Dignity

- suitable for both internal and facade works.

- long-term viability of the solution - this allows you to knead several bags of a mixture with a concrete mixer without fear that the solution will grab and you will not have time to work out

- durable surface after drying, resistant to mechanical influences

- low cost

disadvantages

- badly clips with smooth concrete surfaces

- for a long time of hardening cement - no less than in 2 weeks are proceeded

For further finish requires a shplan - the impossibility of performing a large amount of work in one day due to heavy exercise

Increased humidity in the room during drying. For crystallization of cement particles, a sufficient amount of moisture is needed, so the posted surface is recommended to be sprayed with water. Increased room humidity leads to the deformation of wooden structures. - dirty job. When the solution is embroodble on the wall, it will hit the floor to the floor, which in itself is unpleasant - when there are many dirt under your feet. Cement particles have a very small fraction, when they knead the mixture, they rise into the air and fall into the respiratory tract, which is harmful to health.

Cement-limestone plaster

Composition: lime, cement, sand.

Dignity

- it is used for exterior and internal works, as well as for premises with high humidity.

- has antibacterial properties that protects the fungus from the appearance

- elastic consistency, making it easy to apply

- has a good clutch with a surface

disadvantages

- Long term of final grazing - 3-4 months

- very demanding on the observance of technologies - with the slightest disadvantages of surface preparation or non-compliance with the rules of drying on the plaster there are cracks or a wall becomes loose

- dust from the lime plastering mixture is very harmful to health, a solution that fell on the skin causes irritation, ulcers may appear

Plaster plaster

Gypsum mixture for plastering walls includes plaster and fillers in the form of mineral additives. Color plaster plaster - gray, cream, or white.

Dignity

- fast drying of plaster allows finishing work in a short time

- does not require putty for the preparation of walls to shook wallpaper

- very plastic, not slipping from the wall in the process

- enough applying in one or two layers, which allows you to twist for the day 30-40 squares of the prepared surface

- less dirt and dust than when working with cement mixtures

- non-shrinkable, not cracking after drying

disadvantages

- small viability of the solution - the prepared mixture must be developed within 40 minutes

- ready backlighting surface unstable to mechanical effects

- unstable to moisture, for this reason it does not apply for external work

Adhesive plaster

Composition: cement, polymer additives, special fibers, sand.

Mainly applied to mount the insulation. You can use for the plaster all the wall using the grid. The high cost of this plaster limits its widespread use for wall alignment.

What you need to consider when buying dry plaster mixes

• Do not take mixtures from little-known manufacturers.

The German company "Knauf" produces very high-quality mixtures for plastering walls. The price of products of this company is somewhat higher than on a mixture of domestic producers, but fakes are more common than on Russian mixtures.

Among domestic producers, the firms "prospectors", "Yunis", "found", "Solve", "VOLMA".

For quality, diligent mixtures are not inferior to the mixtures of Knauff. When purchasing large parties, the difference of 100 rubles per package in 30 kg becomes tangible.

• Foam concrete walls have a porous surface, it is better to align their gypsum mixtures. Cement mortar can be used. But due to the fact that the foam concrete absorbs the moisture, the positive surface will have to spray with water several times.

• Wooden walls are placed in a cement-limestone mixture along the duischette of durank.

• at the cost of gypsum plaster mixes are more expensive than cement. But, if we consider that the consumption of plaster plaster 10 kg per sq.m with a layer thickness of 1 cm, and cement 13-16 kg, then it turns out that not much more expensive.

• Do not purchase a mixture for plastering walls by large parties. Unfortunately, there are a lot of fakes on the market. Take to start a couple of packages, try them in your work. If the collapse time matches the standards - you can buy the required amount of the mixture. Gypsum plaster, which were incorrectly stored very often collapse within 10 minutes after the kneading. Cement plaster, in which "forgotten" to report the desired number of cement will slide along the wall.

High-quality mixtures are packaged in three-layer packaging. Between the outer and inner paper layers, there must be a layer of film. The release time of the mixture specified on the package should be different at least one second.

A good video about the choice of plastering mixtures and their shortcomings, but the Council on mixing cement and gypsum plaster is incomprehensible. You do not need to listen to this advice.

The use of gypsum plaster Knauff.