Heater Isolon: description, dignity and disadvantages Insulation,Building materials

Regardless of which material is taken as a basis for construction, avoid the process of insulation will not work. But it is possible to significantly reduce it and simplify if you use the right insulation. In this article, you will find all the information about the popular material from the brand of Isolon, and then you can decide how suits you to solve your tasks on the building isolation.

Content

Insulation isolon - composition

For the production of insulation of isolon as a basis, polyethylene is used as the basis. By deep processing of this polymer raw material, a fine-like closed-type structure is achieved, formed in the canvas of various thicknesses.

There is a series of insulation isolon, in which the outer surface is a foil layer, due to which high performance characteristics are achieved not only about thermal insulation, but also resistance to another method of exposure - UV rays, moisture.

Important! All modifications of the material isolon today are produced in the CIS. In the finished form, the products correspond to the international standard of the insulation of the universal purpose - the form ISO 9001: 2000-12. What the insulation is insulation looks like, you can view the photo to compare it external differences with other materials of this group.

Types of Isolon

There are 2 types of this building material, the basic principle of the classification of which is manufacturing technology.

Eliminate such modifications of isolon:

- NPE - notchy;

- PPE - stitched.

Depending on the characteristics of the structure of the canvas distinguish the following stamps:

- Cellon PPE 500 and 500-L - the basis of this material is polyethylene, crosslinked in a vertical furnace. As a result, a bound transverse structure is formed.

- Cellon PPE 500 HP is similar to the characteristics material, but horizontal furnaces are used to process polymer raw materials.

- CIOLON PPE 500-300 - the initial polymer mass in production is frozen by chemical, also when using horizontal furnaces.

- Isolon 100 and 100 L - this type of web is distinguished by an unbalanced molecular structure created on the basis of extruded polyethylene.

There is another line of enhanced in certain parameters of insulation:

- with increased wettability of surface treatment with paints and adhesive solutions;

- increased rigidity;

- colored insulation insulation;

- material with antipirens in composition to reduce flammability.

Important! Options for labeling insulation isolon - PSEV, GSE, NPE, PPE.

Depending on the principle of the intended installation distinguish:

- insulation isolon foil self-adhesive one-sided;

- Isolon self-adhesive bilateral;

- Clear without adhesive base.

Specifications

The characteristics of the isolon correspond to the maximum possible parameters with which the high-quality insulation result is achieved:

- Density - 26-45 kg / m3.

- The reflective effect of emission energy of the foil insulation isolon is 97%.

- Water absorption - ≤0.1%.

- Compressive strength - 0.035-0.33 MPa.

- Elasticity - elongation from 130 to 250%.

- Use point - -60 / + 125 ° C.

- Specific resistance - 1.8-1.95 kJ / kg * p.

- The thermal conductivity coefficient of isolone is 0.031 W / MK.

- Density - 26-45 kg / m3.

- Parry permeability - 0.001 mg / MCPA.

- Class of flammability - G2-G4 according to the GOST 30244 Regulation.

- Reduced shock noise - by 20 dB.

Important! The dimensional grid of the insulation isolon is also wide enough. In the construction market you can find a roll material with such parameters:

- the thickness of the isolone is 1-50 mm;

- sheet width - 0.55-2 m;

- length - 2-200 m.

Plates have dimensions 1 * 1.1 and 2 * 1.4 meters.

The advantages of the insulation of Isolon

The technical parameters of the isolon provide its advantages over other materials for insulation:

- Beautiful heat grumbling properties.

- High degree of protection against condensate and moisture, which often eliminates the need to perform waterproofing.

- Absolute ecological purity - the composition does not destroy the ozone layer of the Earth, it does not cause allergies in a person, during combustion does not release toxic substances, does not become fluid, and it disappears in the form of steam and carbon dioxide.

- Excellent shock protection.

- Elasticity and resistance to mechanical damage.

- Ease of processing and molding for a specific type of construction to achieve maximum sealing.

- The stability of the chemical composition - the parameters do not change even with aggressive exposure, including when combustible petroleum products, oils.

- The possibility of combination with any type of material - wood, plaster, concrete, natural stone, lime, metal, plastic.

- Biological resistance - insulation isolon is not subject to the accumulation of harmful microorganisms, mold fungi.

- A long period of operation without reducing the original characteristics - from 80 years.

- A light weight.

- A wide species series of densities, thicknesses, shades of the canvas.

- Simplicity and speed of installation work, especially if self-adhesive isolon is used.

- Low price and cheapening of all construction due to the lack of need for additional consumables and professional skills - installation is easily performed with their own hands.

Important! The shortcomings of the insulation is insolent has no.

The use of insulation isolon

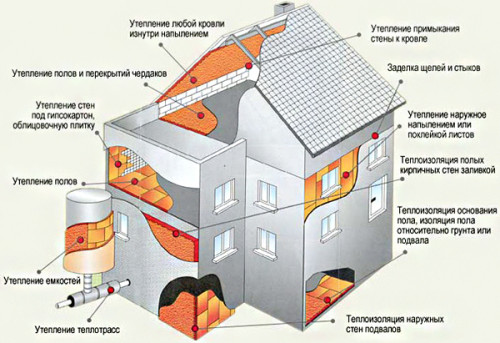

Thanks to the universal characteristics, the insulation isolon has a wide range of applications - as a substrate during parquet, carpet, laminate, warm floor, as well as when insulation:

- engineering systems of pipelines - water supply, ventilation;

- refrigeration and climatic equipment;

- vehicles - cars, cars, engine compartments;

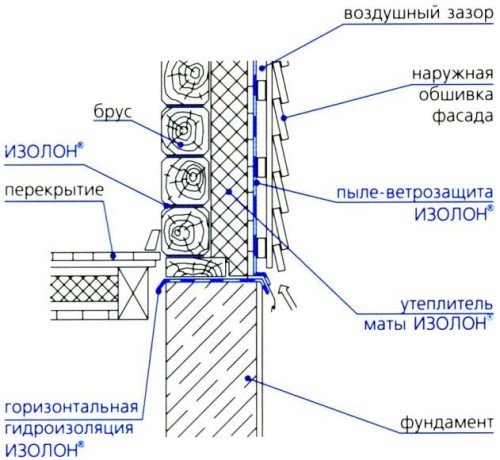

- walls, floors, roofing, basements, floors in residential buildings of various floors;

- utility and household buildings - saunas, baths;

- commercial and warehouse buildings - warehouses, hangars, pavilions.

Important! In addition to the construction sphere, the isolon is widely used in everyday life, in medicine, in leather goods and furniture manufacturing, for packaging various products.

Installation of insulation isolon

According to consumers about the insulation of Isolon, there is no difficulty in the process of laying, even in the absence of professional construction skills.

General installation rules are reduced to the following:

- Choose a suitable thickness insulation, given the characteristics of the configuration and the insulated surface material.

- If necessary, make cutting elements of suitable size and shape. It is convenient to perform a conventional sharp knife.

- When laying a self-adhesive insole, remove the protective film and put the details of the material in the desired order, slightly pressing to the surface.

- When laying a non-self-adhesive insulation, use for fixing glue solutions of type No. 888 or acrylic basis.

- All the joints of the plates are built additionally by mounting tape, brackets from the construction stapler or weld.

Video

To make sure that the process of installing isolone is easily easily viewed the video below.

Conclusion

Based on all the information received on technical parameters, types and rules for using isolon, it can be concluded that this is a new generation insulation. Products of this brand makes decent competition existing on the market, more familiar, materials not only on operational characteristics, but also by simplicity and speed of use, as well as an affordable price.

SUMMARY: Boldly use insulation isolon to solve problems of any complexity and you can save yourself from trouble to improve isolation or restoring it after a short time!