Mirror panels PVC. Characteristics and features of the material Building materials

Repair required in the house Many are postponed in a long box only because of fear spend a round sum. Such savings is not entirely justified: the modern construction market proves that it does not always mean efficiently. In the article you will find all the information you are interested in on the mirror plastic panels - an attractive price and quality material.

Content

Advantages and disadvantages of plastic panels

Plastic, which is used for the manufacture of panels, is considered one of the most practical, long-life and inexpensive materials. He has a lot of advantages and almost no flaws:

- Enhances sound insulation.

- Well tolerate high humidity.

- Mounted on the surface of different types.

- Creates a modern image of the room.

- Quickly, without unnecessary dirt and dust is installed.

- It has an acceptable price for any wallet.

- It has a large selection of textures and colors.

The main disadvantages of plastic panels:

- No eco-friendly material.

- Deformed with a sharp change of temperature.

- Sensitive to mechanical loads.

Mirror panels PVC

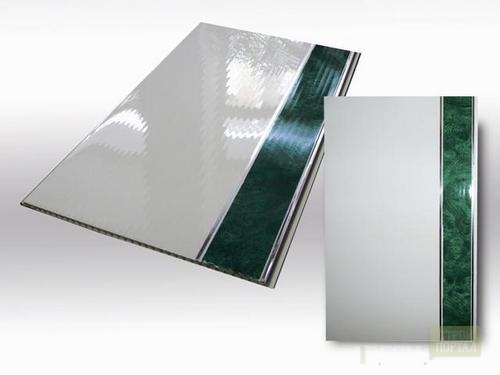

One of the most attractive types of plastic panels is mirrored - durable brilliant or matte glass from polystyrene on the frame. Its surface can decorate the pattern, holographic effect or perforated image, and various shades and shapes provide unlimited possibilities for creating a unique design. The mirror panel covers the protective film, it can be deleted only after the installation is completed. For ease of installation, there are self-adhesive mirrored panels, the price of which is somewhat higher than on the usual.

Application area

PVC mirrored panels are firmly settled both in residential premises and commercial.

In the apartments, this type of decorative facing material has been increasingly moving out of the hallways and bathrooms on the walls and ceilings of bedrooms and living rooms. Very unusually mirror panels transform the kitchen interior. The mirror panels for kitchen walls require more thorough care than surfaces with another coating. This is especially true in the absence of an exhaust: soot, smoke and steam - permanent satellites of cooking food - settle on the glass, making it muddy. The problem is solved by regular "guidance of beauty" with a cleaning agent for glass surfaces.

It is difficult to imagine sports and nightclubs, restaurants and bars without mirror panels, because only this material looks so effectively and unsurpasses "expands" and additionally illuminates the boundaries of even the smallest room. In dance studios and fitness clubs, in addition to decorative properties, the mirrored wall cladding performs an important functional role. And even more, it is advisable to use tile "mirrors" from plastic in small stores of clothing and shoes - for visual increase in space and product range.

Features of mirror panels: pros and cons

Among indisputable advantages are the following:

- Visually increase the small room.

- Due to the variety of shades and sizes, it is perfect in Tandem with other decorative materials.

- Perfectly mounted on a variety of surfaces: concrete, metal, wooden, cardboard, stone.

- Air conditioning and ventilation system, wiring, water supply pipes and heating, is "disgrace" will not be much difficult to hide under the mirror panel.

- Provide a good level of sound insulation.

- Caring for the mirror plastic surface does not take a lot of time and effort.

- Charms in the installation due to its flexible structure and weightlessness. Well lay on convex and concave surfaces - columns and arched openings.

Disadvantages:

- The main "minus" of the mirror plastic material is its "dislike" to water, therefore, before you buy PVC mirror panels, appreciate the level of humidity of the room for which they are intended.

- Together with powerful lamps, the installation of mirror plastic panels on the ceiling is unacceptable - high temperatures are melted. The exception is those mirror panels, the surface of which is equipped with a special coating. They are also suitable for the bathroom. The temperature threshold should not be above 60 ° C.

- It is impossible to install in close proximity to the fire - the material of the fuel.

- If there are even minor roughness on the surface, the panel will distort.

What to pay attention to when buying

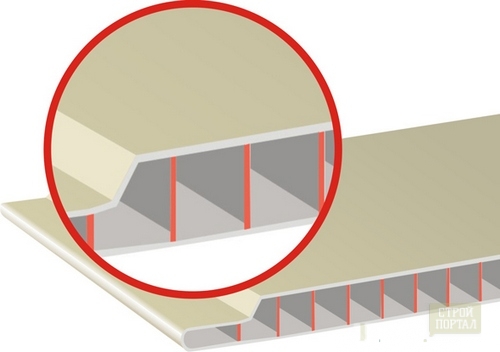

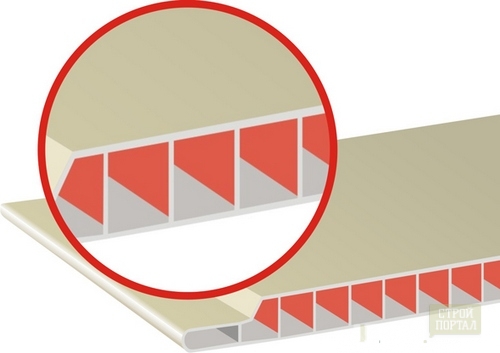

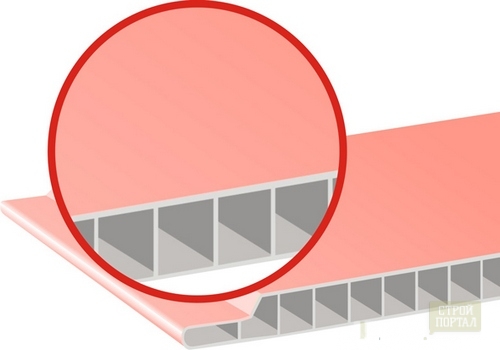

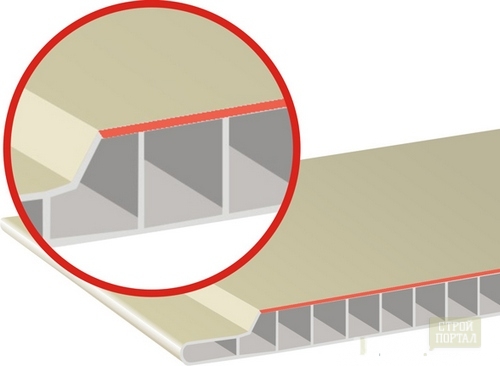

The strength of all plastic panels is determined by the condition and number of rigidity in their design: they need to be viewed first. From the product, on the surface of which their traces were fired, refused immediately - the material is poor quality. Based on which criteria it is worth buying mirror panels, a photo will be prompted:

- The number of rigidity ribs: than them are less, the product is unstable.

- The ribs of plastic tiles must be integer and straight.

- The surface of the PVC panel should be evenly painted, smooth and without irregularities.

- The thicker the facial surface of the plastic panel, the stronger and the well-resistant product.

- Two panels should be highly connected in the location of the docking groove.

And finally, it should be supervised to the package - it should be a whole. The mirror plastic panels are quite delicate material, therefore, even a minor packaging deformation can be negatively affected by their appearance.

Specificity setting of mirror plastic panels

- The mirror panel on a self-adhesive basis is easily mounted and at the same time requires greater attention and accuracy during operation. The surface should be perfectly smooth without residual coating, oil spots, dust. During the installation of self-adhesive mirrored panels, you need to make sure that the entire tile fits tightly to the surface, otherwise bubbles appear on the "mirror". To install mirror panels without self-adhesive foundation, use the crate.

- "Mirror" plastic exists in two versions: panel and roller. And if no questions arise to the installation of plastic panels, then with a material wrapped in a roll, you will have to tinker. During the day before installation, it is sure to roll on the floor for a full straightening, otherwise the panel simply does not fall on the surface as it is necessary. Despite the fact that the surface of the material protects the special film, it is necessary to relate to it carefully and not add to the floor with heavy items that can scratch or ingress the panel. Plastic straightened himself if the roll will expand in advance.

- The temperature difference is displayed on the plastic in the most unpredictable way: the material can nourish or expand. It is always taken into account when installing, leaving a minimum gap between the panels in 0.5 mm, and where the thermometer bar can reach the mark + 35 ° C from 0.8 to 1 mm. The unarmed eye will not be noticed this slit, but you can not worry if the material suddenly increases in volume.

- The mirror plastic panel is cut from the front side.

- If the panels are fixed with the help of a special frame, the surface in the preparation for installation does not need. In the event that the tile is glued to the surface, the base (especially porous or easily absorbing) is treated using dispersion glue.