Chimneys for solid fuel boilers Useful advice

To maintain a comfortable microclimate in the premises, heating with solid fuel boilers is widely used. The choice of the type of boiler falls on the owner - he needs to decide how the heating system will be organized, as well as to determine the choice of solid fuel (coal, firewood, coke, peat briquettes). In any case, to remove the combustion products, as well as the exclusion of their indoors - it is necessary to establish chimney. Without it, it is impossible to normal and the full functioning of the boiler, depending on it both the efficiency of the heating system and the safety of people in the heated room. Thus, the choice of chimney for solid fuel boilers should be approached with special attention, carefully studied and weighing all the nuances of choice from existing options.

Content

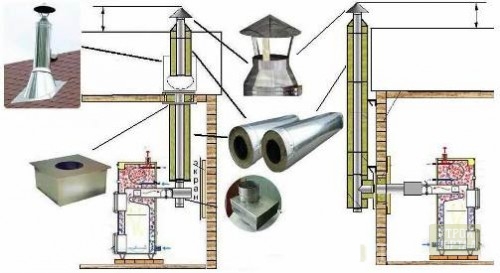

Device of chimney solid fuel boiler

The chimney is a design in the form of a vertical channel, with which the outward from the boiler of the combustion products (flue gases) is made. The main criterion of high-quality installation and chimney is a good thrust. It arises due to the temperature difference and the difference in pressure indoors and outside. The warm air indoors has different from cold air on the street density, as a result of which the air masses move through the chimney. It is necessary that this design ensures high-quality cravings and possessed the necessary heat-insulating properties.

The measurement of thrust is made with the help of special metrological devices - anemometers. The presence of a very weak thrust or its complete absence can define a specialist. It is important to note that the operation of the heating solid fuel boiler in the absence of traction is prohibited.

Parameters of chimney boilers on solid fuel

The main parameters of the chimney affecting the work of the boiler include:

- the chimney cross-section for a solid fuel boiler - to maintain high-quality thrust it is best suited for a smooth-alone chimney of a round or oval cross-section. As an alternative to a rounded, the chimney of a rectangular section can be built - but it must be borne in mind that the angles of the chimney create a jury in which the soot will be accumulated and accumulated, as a result of which the thrust will deteriorate;

- the height of the chimney for a solid fuel boiler - it should exceed 5 meters. In the case of a smaller height, the necessary traction will not be provided. On the contrary, if the value exceeds ten meters, the fuel will be burned too quickly, which is unprofitable economically. The necessary height (or the minimum height) of the chimney is usually indicated in the passport on the equipment of a solid fuel boiler, and must comply with the manufacturer's recommendations;

- the diameter of the chimney for a solid fuel boiler - the selection of its magnitude must be made in accordance with the value specified in the passport. Some changes in the diameter value in one direction or another - no more than 5 mm are allowed;

- the length of the chimney for a solid fuel boiler - to the boiler can be made both vertical and horizontal connection of the chimney. In the presence of horizontal discharges of the chimney, their length should not exceed 1 m;

- its heat resistance - the temperature of combustion products may be different, and reach 600 ° C. Consequently, the thermal resistance of the chimney is a very important factor when choosing a material - usually use heat-resistant brick, steel, ceramics, sometimes glass;

- the design of the chimney is the smaller it includes horizontal, as well as narrowed areas, the knees, the better the thrust will be. This is due to the fact that the flue gas flow is moving in chimney along the spiral trajectory. Meeting on its way of obstacles (in the form of bends, convexities, as well as surface roughness), the flow changes the direction, as a result of which gases are stirred.

Varieties of chimneys

There are the following types of chimneys for solid fuel boilers - depending on the type of material:

- Brick chimney for solid fuel boiler - refractory brick has a wide range of useful characteristics, as well as many years is a traditional choice for chimneys of furnaces. For the equipment of modern solid fuel boilers, equipped with automatic, this selection is undesirable. This is due to the fact that the inclusion of the boiler occurs automatically only when the temperature is lowered in the room below a certain level, besides, the modern efficiency boilers are significantly higher, and they are warm inward. Therefore, the chimney remains cold most of the time, and there is an accumulation of condensate from chilled water vapor, soot, flue gases. This condensate is a rather aggressive liquid consisting of acids - an actively destroying brick chimney itself, as well as adjacent finish.

- Steel chimney for a solid fuel boiler - produce stainless and black steel. Black steel is destroyed under the influence of condensate and soot, so chimneys from this material in solid fuel boilers are not recommended. Stainless steel with special additives (nickel, molybdenum, titanium) as a chimney pipe is capable of withstanding significant temperature loads, has resistant to the effects of condensate media. There are one-way and double-wall (sandwic) varieties of steel chimneys, the first ineffective in the presence of severe frosts.

Sandwich chimneys for solid fuel boilers have a number of benefits:

- good thermal insulation;

- do not accumulate condensate;

- convenience of mounting and maintenance.

Among the shortcomings, it is possible to mention a fairly high cost and a limited term of operation (ranges from 10 to 15 years) - after which the replacement will be required.

- Ceramic chimney for solid fuel boiler - characterized by excellent refractory indices (up to 1200 ° C), resistant to condensate and atmospheric phenomena. Its advantages also include low weight, ease of installation and high fire safety. Ceramic chimney can be installed not only indoors, as well as on the facade of the building.

- Coaxial chimney for solid fuel boiler - is a hermetic system consisting of two pipes. One of them enters cold fresh air outside, and the smoke is given on the other. Coaxial pipes provide combustion of fuel in the boiler is absolutely isolated from heated space. This type of chimney is suitable if indoors are not possible to organize a constant influx of fresh air. Coaxial pipes significantly increase the efficiency of the boiler, its environmental and fire prevention characteristics.

- Glass chimney for a solid fuel boiler is a reliable option with excellent performance. It is distinguished by resistance to corrosion, as well as the original design. Glass chimneys are widely used in many countries, in our parts are not too common due to high cost, as well as the complexity of installation.

Requirements for chimnets

Regardless of the choice of the chimney material, its design must strictly comply with the solid fuel boiler chimney requirements:

- provide reliable cravings, that is, high quality, out of the boiler outward combustion products;

- have sufficient thermo- and fire resistance;

- the installation of chimney should be made according to the requirements of fire safety.

Video examples of chimneys for solid fuel boilers: