Filters for a well on the water with their own hands Useful advice,Plumbing

It has long passed the time when coming to the country area, many had to wear water from the well. Now every summer resident wants to maximize its farm and trying to drill the autonomous well to always be with water.

Content

As a rule, such autonomous water supply takes place close to the central water intake and due to the fact that the aquifers are placed near the bulk rocks, then unnecessary impurities fall into the well. It is possible to use such water to conduct gardening and garden work, but after some time the pipes will begin to stir, and the submersible pump will fail. To avoid this, you need to install water filters from the well.

What do you need a filter

Water purification filters from wells are designed to purify the wellbore and water barrels from garbage and sludge.

Task filter:

- Get good quality water. Despite the expensive equipment of wells on the water, it must necessarily undergo a certain degree of purification. It is also necessary to reduce the level of rigidity, mineralization and decrease in the concentration of manganese, iron and fluorine. Depending on the chemical composition of water, different filtering systems are used.

- Take care of the durability of the equipment and the well itself. The impurities can so much to fill its trunk that it will be impossible to use it. Therefore, there is a frequent hill of the well.

- Caring for hydraulic equipment. Pumps are not intended for work under an increased load (water lift together with solid particles).

What are the filters

Most often, mechanical filters are installed for water wells. Such adaptations purify water mechanically.

Filters can be divided into such subgroups:

- Mesh.

- Perforated.

- Wire.

Consider the main differences of devices of filters for wells.

Mesh filter

If the well drilling was performed in unstable soft rocks, in which sand-clay deposits prevail, it is necessary to install a strainer. The size of its cell ranges from 0.12 to 3 millimeters.

The main advantages of the mesh filter:

- long service life;

- easy to mount directly in place during the drilling of the well;

- just remove for preventive replacement or replacement to a new filter;

- small in size;

- it has a simple design.

From the disadvantages note:

- it is impossible to completely clean the water from small impurities;

- has a high cost;

- has a negative impact on the productivity of the well;

- if the water contains a large percentage of iron and carbonate compounds, the filter cells are quickly clogged.

Perforated filter

The device of such a filter is simple: it consists of a pipe in which there are round or sloping holes. Slit filters for wells have a solid perforated part, as well as additional belts that enhance rigidity. They help the device to withstand a significant mechanical load.

If there is a question of which filter is to put on the well, then experts recommend installing perforated filters in wells that have a small pressure. Due to the fact that over time the holes are gradually stolen, the performance of such a filter decreases.

Cleaning devices are used if water lies in pebble or limestone sediments. A, here is a very small fraction, for example, sand - perforated filters will not be able to delay.

Have such filters and different costs. It fluctuates depending on the material from which they are made. For example, if the filter is made of plastic, it will be much cheaper than a similar instance made of stainless steel. For homemade filters for wells, it is necessary to take into account the well material. If it is plastic, then the filter must be made from the same material.

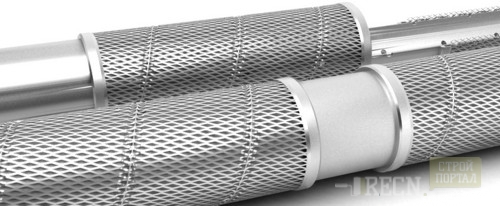

Wire filter

This is the most durable and durable filters. They are made exclusively in the factory conditions. The service life of the wire filter for the well is more than ten years.

Consist of pipes having a sliding or round perforation on which parallel wire rods are additionally welded.

Gravel filters

Gravel filters are such types:

- devices that are collected on the surface of the gravel circuit to then pull it into the well. The thickness of the layer should not exceed 30 millimeters. Filters can be block and casing. The first is produced in two versions: hollow and monolithic;

- the flowing filter is arranged as follows: gravel falls through the holes of the intercoupled space. Used for wells with a diameter of more than 100 millimeters (in place for the filter part).

The applied material for sprinkling is a homogeneous gravel, having rolled particles and a mass fraction of quartz (at least 95 percent). If inhomogeneous particles will be present in the gravel mixture, then the insightful ability of the filter can significantly decrease. It will affect the well performance. Therefore, experts are not recommended to perform its backfill with crushed rocks.

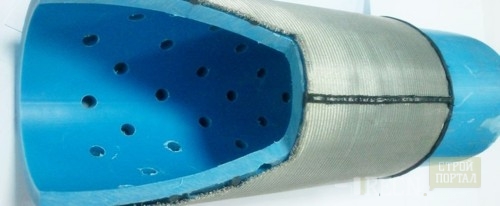

The photo shows a diagram of a filter device for a well, which cleans water from iron:

Filter for Abyssinian Well:

Filter of rough cleaning for wells:

Well filter with their own hands

It will be better if you install a filter for cleaning the water of factory production. But not always such an opportunity. And it is necessary to clean the water, so the device for cleansing water from foreign impurities can be made independently.

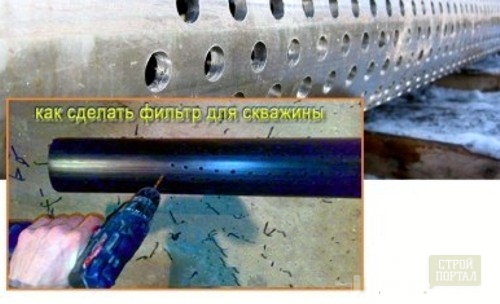

Many believe that it is necessary to just take a cut of the pipe and do holes in it. Yes, you can do this, but it is better to improve the design of the standard perforated filter.

The manufacture of filters for wells will not be much labor if you do it according to the rules.

To make a mesh filter for a well, you need to prepare such materials:

- steel pipe of the corresponding diameter. You can take both plastic, but then it is necessary to choose the material that will be safe for the human body.

- drill;

- drill;

- grid;

- truck made of wood.

Before proceeding with the work, select the diameter of the drill. The size of the opening will depend on the composition of the breed.

Step-by-step instruction:

- Measure the length of the sump.

- The pipe must be put on the ground (or any horizontal surface) and put markup. It is necessary to take into account that the segment with holes in the pipe should be twenty-five percent of the pipe length and have a well-driven well. Therefore, on each side of the pipe, you need to leave fifty centimeters.

- We proceed to drowning holes. Take a drill and back from the edge of the pipe. Drill the first hole.

- Continue drilling holes at a distance of one or two centimeters, and they must be arranged in a checker order.

- Try to drive holes at an angle from thirty to sixty degrees, starting from below and moving up.

- After all the holes are ready, read the edges and lift the pipe. You need to remove the chips, which can be clogged inside and close the holes.

- Take a wooden cork (chopper) and close the bottom of the pipe.

- To improve and protect the design of the homemade filter for the well, you must apply a grid. It will prevent ingestion of the holes in the shallow breed.

By the same principle you can make your own filter for a well on the sand.

How to independently make a slit filter

Drilling metal - the task is not from the lungs, and if you do not work, do not rush to throw out a spoiled pipe. From it you can make another filter - slit.

Materials and tools for a slot filter:

- pipe (metal or plastic);

- metal wire;

- metal mesh or plastic;

- welding machine or special non-toxic plastic glue;

- bulgarian or cutter.

How to make a slit filter:

- To make a water well filter, you must have a grinder or cutter for welding in the arsenal.

- Using the tool, make small slots in the pipe (slots). They should be located at a distance of two or three centimeters from each other. In this case, the pipe will not bend under load (if it is plastic).

- After that, you can take a thick metal wire and winding it onto the pipe. Winding "Step" should be two or three centimeters. This is necessary in order to make a mesh frame.

- Then take the metal mesh (with small cells) or a grid of plastic or metal and over the wire wrap it into one layer.

- Break the ends of the grid, after performing several seams with a welding machine. If you work with a plastic grid, then use special moisture resistant glue (be sure to choose non-toxic!).

Important! It is impossible to flood the well cement, because it is possible that the filter will need to be replaced or repair.