Mortar for plaster: composition, proportions, fabrication Building materials

Mortar - it is one of the most versatile solutions used in the whole complex of construction works - pouring the foundation, the construction and strengthening of walls and their cladding. We offer you information that will help in the selection and use of compounds at all stages of construction, as well as in the preparation of their own hands.

Content

A bit about the kinds of

What is a plaster? In fact, it is the easiest and a protective leveling layer, which is applied to the desired surface in a specific amount that provides a strong protection against the impact of external factors and the ability to use the basic lining material more effectively.

Standard mortar composition is very simple:

- lime as a binder;

- river sand;

- water.

The main advantage of such a composition - environmental friendliness, safety in use and the absence of unpleasant odor, it can be used in residential areas without any problems. Despite the fact that the components are very simple and lime mixture used in modern decoration works constantly.

Lime itself can differ significantly - white, gray, carbide, hawed, overexheared or hammer. But any of the species provides high strength and ease of use. However, there are a number of weaknesses: the ability to use most of the compositions based on it only in dry rooms, weak atmospheric stability and sensitivity to the effects of external stimuli.

Cooking lime plaster with their own hands

Initially, you have to choose which limestone plaster will be the best option for your purposes. For residential premises with standard moisture indicators, cement-lime and lime-gypsum plaster are most often used. For external work, they are not suitable for their susceptibility even to the minimum impact of moisture.

In order to independently make a lime solution for plaster, it is necessary to carry out two simple steps:

- Prepare a dry mix of selected components.

- Carefully dilute it with warm water.

Capacity for mixing can be any. It all depends only on the area to be treated, your tools and surface features, where the solution will be applied. The only requirement for capacity is even bottom. The lime itself is poorly mixed with water, so in the corners and deepends it can remain. And this is the main reason for improperly consistency of the solution and larger interpretation of the mixture.

To fully prepare a solution ready for use, it is necessary:

- fully clean the bottom used tank from dirt and any foreign objects. If possible, it is also necessary to align it if necessary;

- on the purified bottom of the tank, fall asleep with a flat layer sacred pre-sand;

- on top of its area evenly distribute lime;

- stir the components to a homogeneous mass and to dissolve;

- fall asleep some more layers of sand and lime, just repeating the two steps.

Even if at this stage you will not work evenly mix the components, when the water is added, it can still be mixed more carefully.

If you want to save your time and strength, you can use a mixer nozzle that is installed on a conventional electric drill.

Note! Water in the mixture must be added gradually in small portions. After each portion, the whole composition needs to be mixed to a state of homogeneous mass. Otherwise, lumps are formed, which are quite problematic.

Depending on the application method used and the surface characteristics of the instruments, where it will be applied, the mortar itself and proportions may differ significantly. Typical ratios are as follows:

- izveskovo-sand - 1: 4;

- of lime-cement - 2: 1;

- lime-plaster - 3: 1.

The ratio may be different components. It is equally important to determine the viscosity of the solution. This is not difficult. Take the blade, which has just been stirred solution or flat metal object, dip it in the solution and immediately lift. If the liquid drains quickly and leaves virtually no residue on the surface, then water too much and need to add other components. It should be done gradually, regularly checking the consistency. If the situation is reversed, you just need to add warm water. Too thick solution - not the most convenient to use the material. Best of all, when the solution is uniformly fall on the blade with a thin, but continuous and dense layer. It is a sign that, as on any other surface it is reliably strengthened.

Plastering mortar should be dry before you will further tiling. complete drying rate is directly dependent on the constituents, the temperature and humidity in the room where it is applied. The most quick-drying solution - lime-plaster. He dries in just 10 minutes. Sometimes a little longer. Most slow-drying - lime-cement. Him to complete drying requires at least two to three days. On this basis, you can decide which solution is best suited for you and that will not slow down the repair work.

Mortar: characteristics and complexity in manufacturing

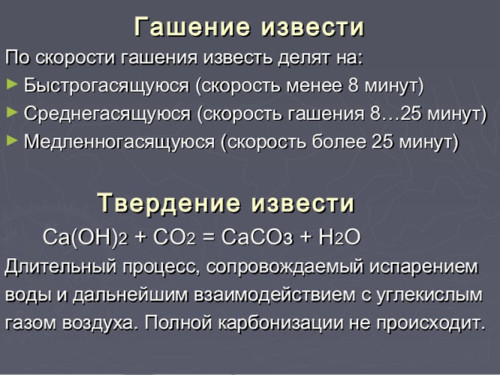

Addressing this issue, you must first focus on the kinds of the most lime. It is slaked and quicklime (main types). Only the slaked lime can be used for mortar. But the process of extinction may take several weeks, which significantly slows down the finishing work. Therefore, many prefer to buy mortar and insulate themselves from the extra hassle. Especially because even after the desired period of lime can not meet the required quality. It may remain outstanding lumps. After applying the resulting solution onto the surface of the walls, cracks occur and small mounds, adversely affecting the appearance and further complicating operation.

Alternative - Fasting Lime. The final price for a lime solution when calculating will be higher, but you do not have to wait for a week, without having no guarantees that the solution will eventually be as needed.

Read more about the manufacture of different types of plaster

Lime-gypsum plaster

Rapidly solidified, it has high durability and lack of problems in manufacture. For external work, it is not intended due to the susceptibility of the gypsum to high humidity.

However, the presence in the composition of gypsum greatly simplifies work with a solution. It dries quickly and grabbed at room temperature in just a couple of minutes, and its complete drying and hardening occurs already after half an hour.

In the process of manufacturing such a mixture, do not knead its large amount. You can simply do not have time to use everything. Maximum volume by one occasion is 4-5 liters.

To independently make such a solution, it is necessary:

- Mix the simple solution of lime according to the instructions indicated above.

- Subject to the mixing of five liters, we remove three of them in a separate container.

- The released space partially fill in plaster and water.

- Remove mixture before return into the container and carefully mix well. Please note that you have only 2-3 minutes.

- Use a solution for 5-6 minutes, otherwise it will begin to harden.

Lime-clay plaster

In its composition, clay and limestone dough. The ratio of quantity: 1: 0.5, respectively. You can also do one to one. You also need to add to 1/6 of pure sand.

The clay dough itself is obtained from career clay or clay powder, which divorces warm water. Such a mixture must be broken for several days, after which it is typing through a small grid to get homogeneous material.

To independently prepare such a solution, it is necessary:

- Mix clay and lime in the above proportions.

- Gradually add water with sand into the solution, thoroughly stirring.

- In the case of high viscosity of clay, add sand.

The convenience and practicality of the use of such a solution is easily questionable, but it is simple, economical and completely environmentally safe. However, in itself does not differ in high strength. Therefore, most often used in composition with other solutions. To increase strength, you can add a straw, chips or wooden sawdust. But it is more reliable to add cement or gypsum.

Lime-cement plaster

Excellent option for use in high humidity. Most often used prior to laying the tiles in the bathroom or indoor swimming pool. At the same time, it remains one of the simplest in the preparation of solutions.

Relation: 1 part of cement, 3-5 parts of sand, 1 piece of limestone test.

Preparation of such a solution takes the minimum amount of time and effort:

- Mix in the tank cement and sand in a dry form.

- Add diluted with water in a ratio of one to one hated lime.

- Mix and, if necessary, add water to adjust the consistency.

Some simple tips finally

As you can see, the preparation of a lime solution is a simple process. However, many in the desire to save their own time are buying ready-made solutions in construction stores. Naturally, they differ in their quality and cost. If you do decide to buy ready-made solution, instead of doing it yourself, here are a few tips:

- Do not save. Price and quality are directly interrelated.

- The well-known brand of a lime solution is a guarantee of good quality.

- Make purchases from proven sellers in large stores of building materials or directly from the manufacturer.

- Before buying, check the integrity of the packaging. Moisture or debris is unacceptable.

We hope our advice will help you in choosing and make any repair work in your home easier, easier and cheaper. Make a choice with the mind, and you will always find yourself in winning.

New comments

Add a comment

To send a comment you need authorize.

why can't copy information about making a lime solution ????

auuuuuuuuuuuuuuuuuu