How to mount pipes made of stitched polyethylene Plumbing

Pipes made of stitched polyethylene, as well as pipes from metal, are used to improve various pipeline systems, both domestic and street. And as practice shows, they are no worse. Moreover, the pipes from this material have recently received very widespread due to simplicity in use and relatively small cost.

Content

Properties that are inherent in pipes made of stitched polyethylene

Pipe material - stitched polyethylene, for heating and water supply in construction is most often applied.

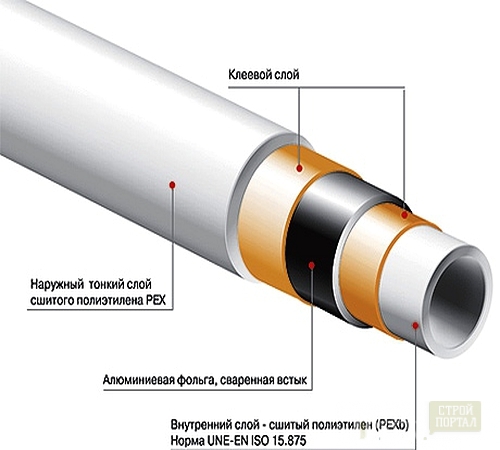

Polyethylene is called a well-known polymer used in many areas, which is obtained by polymerization of ethylene. The process of "stitching" of polyethylene is to transform its inner molecular device without changing the chemical composition.

Upon completion of this process, the material acquires useful qualities that did not possess before, which makes it possible to apply it much wider than before. The advantages of polyethylene pipes are considered as follows as:

- strength and inconsistency of the action of large temperatures;

- exposed to high temperature (up to 200 degrees) does not change the configuration, subject to the absence of pressure;

- resistance to cracking;

- even at a very low temperature (up to -50 degrees), great stroke resistance remains;

- balance is based on the indicators of hardness and elasticity;

- is a difficult material;

- it has the properties of shrinkage, i.e. Some time after stretching, he takes an initial form;

- resistance to the action of various chemistry;

- anti-corrosion properties;

- the absence of heavy metals;

- can be bend freely and do not break;

- low weight and size;

- ideal smoothness;

- elasticity. Due to this property, there is no need to use additional connectors;

- the ability to clean sound and mechanical vibrations;

- large service life.

But, like any material, stitched polyethylene pipes have some drawbacks. These include the following properties:

- brass fittings that serve to connect pipes should not come into contact with the screed and plaster. It can provoke corrosion and, as a result, a violation of normal operation;

- the direct sunlight should not penetrate the water supply system, because because of it, a large number of bacteria can spread in water.

Required tool for stitched polyethylene pipes

- trubores or scissors to ensure a smooth cutting of the pipe before compound;

- a collet expander who serves to expand the end of the pipe to facilitate the introduction of the fitting into it;

- spanners;

- vice for pressing;

- fitting, crimp nut, split ring.

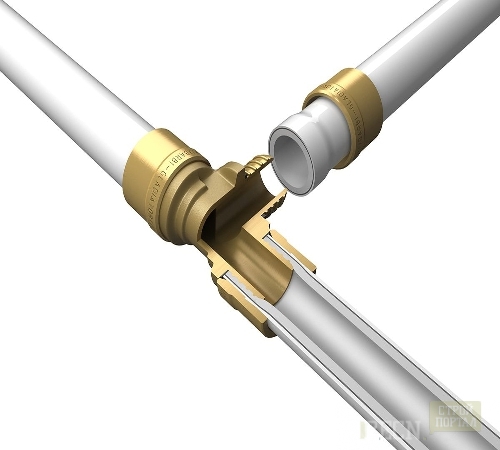

Fittings are nodes with which pipes are connected. Fittings are called a variety of connectors: clutches, squares, tees, etc. They also differ in the compound method. There are threaded, capillary, compression, pressing fittings.

Installation of cross-linked polyethylene pipes is usually carried out in one of two ways:

- using compression fittings;

- using a pressing fitting designed for polyethylene pipes.

Mounting the pipeline using compression type fitting

This type of fitting is distinguished by uncomplicated installation and can be used both when laying pipes with cold and hot water. To connect pipes, you will need a minimum of tools: pipe cutting and a key for tightening nuts.

Connect pipes using a compression fitting as follows:

- first, the crimp nut is put on the pipe;

- following a split ring, which should be located in one millimeter from the end of the pipe;

- next, the pipe is put on the fitting of the fitting, until it widespread into it;

- then the crimping nut is twisted by a wrench. In the process of twisting, it is important not to overdo and not damage the pipe.

Mounting of the pipeline using a fitting of a pressing type

Attaching pipes using a pressing type fitting is very durable and reliable, but it is indeplicable. In addition, to implement this, applying this method, it is necessary to use pressing vice.

Mounting pipes with the use of a pressing fitting is happening like this:

- the pipe is clamped by a solid nut;

- the expander is introduced into it and promote until it is felt;

- at the same time stretch the pipe with its help and delay for about a minute;

- the fitting is injected into the pipe. The material from which the pipe consists, due to its properties of the reverse shrinkage, then will then take the original shape and size, after some time the removal of the pipe from the fitting will cause difficulties;

- the sleeve is pressed on the fitting through the tool for pressing.

Despite the fact that combining fragments of pipes from stitched polyethylene is quite simple, when performing this work, you need to be extremely attentive and neat.

For the construction of the pipeline system as a whole, it will take the scheme of its location, on which the exact dimensions and gaps between the nodes will be fixed. Next, it is necessary to make a estimate in which it is necessary to take into account the number and cost of the necessary materials: connectors, cranes, pipes, etc. The diameter of the cross-linked polyethylene pipes ranges from 1 to 16 cm. Before you start work, you need to choose suitable for specific purposes.

To compile a scheme, you can use special programs or expert advice. Upon completion of the work on the scheme and thorough check, it is possible to start the markup of the walls of the room in which the pipeline will be laid.

During operation, you should not forget about the necessary maintenance. If the installation of the pipeline is performed correctly, even when it fails, the repair will be carried out much easier.