How to learn to plaster wall Walls

Each repair begins with the preparation of walls to the finishing finish. In order for them to bring in perfectly even state, two types of plaster - "dry" and "wet" are used. The first option involves the walls of the walls with plasterboard and other similar materials. Technology facing the surface "dry" method is described in the article " Wall Facing Technology Plasterboard».

Content

The "wet" way of finishing the walls implies the use of plastering mixtures. Despite the fact that it is quite time-consuming, the classic method of wall decoration is used very often.

Do you need to plaster the walls?

The main purpose of the plaster is the alignment of the walls. But besides this, it protects them from moisture penetration and, accordingly, extends the service life of building materials. The availability of all components of plaster and tools for carrying out work allows it to be made independently. For this, it is enough to know the basic principles of plastering walls and the procedure for this.

The better plastering the walls - the choice of material

Our market offers a large selection of mixes ready for use. They are quite expensive, but have certain advantages.

- Silicone plaster - universal material, the most expensive of similar blends. It is easily cleaned, elastic and durable.

- Acrylic plaster - finished mixture based on synthetic resins. Also has high elasticity and low absorption. Disadvantages - worst vapor permeability in comparison with mineral mixtures and sensitivity to ultraviolet.

- Mineral plaster - used for work both inside and outside the building. It is resistant to sunshine, has durability and high vapor permeability. It consists of mineral fillers, cement and additives. Such a mixture is perfect for premises with high humidity and walls made of high vapor-permeability materials - such as cellular concrete. The silicate plaster, the binding material of which protrudes the liquid glass is also related to the mineral.

Despite the advantages of thin-layer plasters, cement-sand, lime and gypsum mixtures remain the most popular. This is explained by the availability of material and its qualities. Such mixtures are sold at a finished form or are made independently.

- The cement-sand mix is \u200b\u200bconsidered the most durable and at the same time cheap. Such plaster is not afraid of moisture and is suitable for leveling any walls, including significant defects or poor-quality masonry. The disadvantage is low plasticity, so plasticizer is added to the finished mixture. Solutions proportions: 1: 3 (cement and sand, respectively).

Cement mortar is used for an hour after cooking.

- Lime plaster has good plasticity, but in strength is inferior to the previous version. There are several types of such a mixture:

- cement-known: 1: 1: 4 (cement, lime, sand);

- Lime: 1: 3 (lime, sand);

- Gypsum-lime: 1: 3 (dry gypsum, limestone dough).

The gypsum mixture is easy to use and when it is assisted, a very smooth surface is created. It is resistant to cracking and has good vapor permeability. Material based on plaster plastic is conveniently applied to the surface and quickly freezes. That is why it is prepared in small portions and immediately use it.

Plastelling the walls ourselves - work tools

- Capacity for solution.

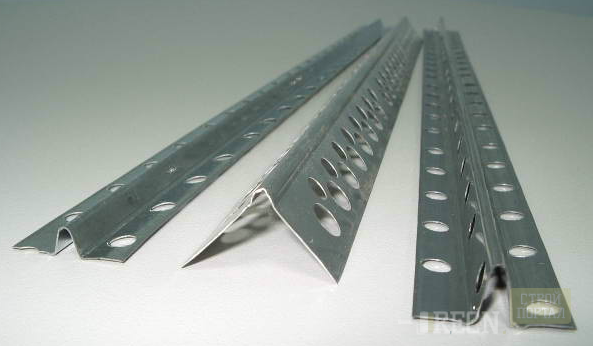

- Metal profile for the device of lighthouses.

- Scraper - trapezoidal metallic blade.

- Falcon - wooden or metal shield.

- Kelma is a heart-shaped blade.

- Halfury and grater.

- Metal brush - for surface cleaning.

- Master OK.

- Rules.

- Plumb.

- Level.

Plastelling the walls with your own hands

Preparation of the room

The preview preparation includes actions aimed at protecting the surrounding environment from damage. All things are taken out of it, and the furniture is shifted in the middle and covered with a film.

Outdoor coating should also be covered with solution. It is closed with a film or fall asleep sawdust. Chandeliers and lamps are removed, and the wires are isolated.

Cleaning and preparation of walls

The next step will be the preparation of direct walls:

- If they are plated by wallpaper, they are chosen by water and then removed or believed with a scraper.

- Any old coating, whether it is paint, whitewashed or squeezing plaster must be completely removed. Otherwise, the new layer can move away from the wall.

- To verify the strength of the old plaster, the surface is closed with a hammer. If at the same time there is a deaf sound - the coating is adjacent tightly, if it is ringing, then this place is cleared.

- Small cracks are expanded with a knife, for large chips, the grinder is used.

- Then they are filled with a solution and are sampled by a plaster grid.

- Preparation of various surfaces to plastering has its own characteristics. On the walls of concrete, a stone or brick chisel or an ax, a blank is made, the depth of which is about 10 mm. Due to this, the plaster is more reliable on the surface.

- How to stucify the walls from wood? This surface requires special preparation. In order for the plaster tightly held, a grid of duncas is stuffed to the surface. At the same time, nails are clogged to half, and the rest of them are bent. Instead of duncas, it is possible to use a metal mesh.

Grinding wall

After the procedures, the wall is cleaned from dust and dirt and ground. Some masters skip this stage, considering it insignificant, and use water, especially when working with cement-sand mixtures. But the primer, penetrating into the thickness of the concrete, increases the adhesion of the surface and protects it from dampness. It stabilizes the porosity of the base and allows you to evenly apply plaster.

Depending on the material of the surface, concrete contact, the soil or soil is used super contact. Antiseptic impregnation is used for wood. The primer is applied with a brush or roller in one or two layers - depending on the degree of water absorption.

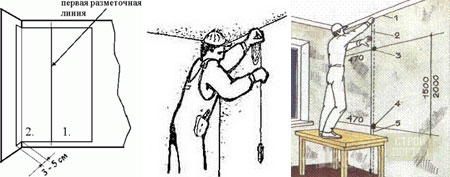

How to sting the walls of the house - I exhibit lighthouses

- Using the level, the vertical of the surface is checked.

- Below and at the top of the wall screws screws or dowels rush.

- A fishing line is tied to screws and exhibited vertically.

- In the same way, the horizontal fishing line is pulled, 4 lines will be enough for a wall height of 3 m.

- Under the line vertical, the slides of the solution are formed.

- The profile is pressed into a mixture to easy contact with a fishing line.

- In the same way, horizontal lighthouses are exhibited.

- The resulting grid is checked by the level - to find in the same plane.

Preparation of solution

With independent preparation of the solution, the layer is taken into account for which it is intended:

- 1 layer - spray. For it, the solution must have a sour cream consistency. Maximum thickness of a layer of 5 mm for a concrete or brick base and 9 mm for wooden walls.

- 2 layer (up to 10 mm) - soil. Prepared test solution.

- 3 layer - covering. A solution with fine-grained sand, creamy consistency.

When using the finished mixture, carefully examine the instructions printed on the package and act in full accordance with it.

How to plaster walls - apply mortar

- Celma is used to apply the first layer of plaster. It is applied a small amount of solution, and it sprinkles on the wall. The brush with the brush should be sharp, but not too smoother and strong, otherwise the prepared mixture will fall not only on the wall, but also on everything surrounding it.

How to plaster walls, video:

- The soil is applied over the spray with a grater or a wide spatula. Depending on its thickness, the work is carried out in one or more "goals". The last layer is equal to the Rule of Lighthouses.

- On top of the wet soil is applied by a layer of the cross.

How to learn to plaster the walls - final work

- Removal of beacons and grout by a mortar.

- Alignment - with the help of a spatula, all the depressions and tubercles on the wet solution are carefully smoothed.

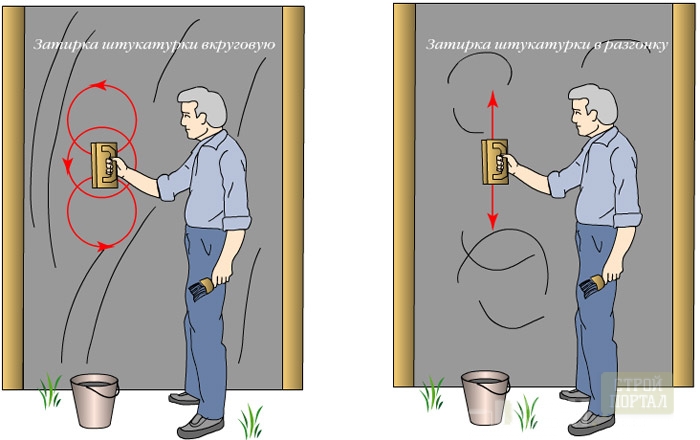

- Grout - Perform circular motions on the helix. The plane of the grater is tightly pressed against the surface.

- Clean grout. Performed by spongy or felt grater.

How to plaster walls correctly, video:

Some Soviets

- The porous base is ground twice.

- Gypsum plaster is finally loaded no later than 4 hours after overlay.

- Metal lighthouses must be removed after the overlay of the last layer.

- If the surface is prepared for trim with ceramic tiles, then one layer of plaster and do not align it.

- Walls in two weeks after the completion of the work when applying a gypsum solution and after 30 days with cement-limestone plaster.