How to independently carry out excavation works using earth drill Construction,Plot.

Earth drill - a tool that can be used with a minimum of effort and time to prepare the hole in the ground. To learn how to make their own hands a manual drill for excavation works and how to use it, it will be discussed later.

Content

Scope of Use and the dignity of manual drill

Earth drill manual is indispensable, if the use of a drilling rig, electric or gasoline tools is not possible or is not rational. Earth auger buy or make recommended if to be done:

- installation grape columns;

- installation of drainage system;

- columns installation for fencing;

- the construction of the gazebo;

- construction of the columnar (bar-rostverkovogo) a foundation;

- drilling operations.

Advantages of the tool are as follows:

- design simplicity and maintainability;

- it does not require considerable effort to use;

- security;

- reliability: sharp screws easily deal with the roots of trees and small stones.

Useful tips on the use of borax

- To install poles and device wells is recommended to buy a drill for excavation diameter of 7 - 11 cm.

- In the case of wells of great depth, it is necessary to use rods that are increased by a threaded connection.

- To facilitate the work in drilling deep holes by using a tripod.

- If a manual auger drill stuck in the ground, turn the tool counterclockwise help a pipe wrench with a pipe, fitted on its handle. For convenience, the horizontal auger handle can be temporarily removed.

Weights for drilling wells of great depth

Tip: buy a drill for excavation works hand-efficiently in the event that will do a lot of work. To drill several holes easier to take tools for rent.

How to make a manual drill

Before you decide to buy earth auger manually, we recommend you to get acquainted with its manufacturing technology in the home. This will save money and get a quality instrument.

To work need the following set of tools and accessories:

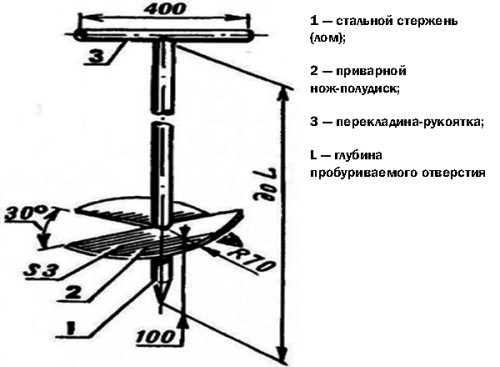

- 25-32 mm diameter steel pipe for a rod, and the beam-arm (selection depends on the diameter and depth of the drill blades of future wells);

- steel sheet of 3-5 mm thickness of 9 (for the manufacture of blades);

- workbench metalwork;

- clutches;

- bulgarian with a cutting and grinding wheel for metal;

- welding machine;

- electric drill with a set of drill bits;

- hardware (bolts, engravers, nuts).

Note: Preparation of drawings is required. Bur for excavations can be made arbitrarily choosing the size of parts.

We produce parts for the drill: a phased description

- Blanks for screw-half-disks (blades) cut from sheet steel by grinders. To give the blank the correct shape, treat edge grinding wheel. The cutting edge sharpened at an angle of 45-60 degrees.

- In the center of the preform drill hole, whose diameter must be 1 mm larger than the diameter of the central rod.

- Bushings for screw attachment blades, extension rods and sticks must be ordered in the turning shop. Another method involves attaching the blades to their welding rod. Plane half-disks (blades) should be placed at an angle of 30 degrees relative to each other.

- The lower end of the rod, manufactured from a tube equipped with a sharp tip, for which the pipe is flattened and sharpened in the form of peaks.

- With sleeve attached handle (also made from a pipe) with a width of 400-500 mm. To do this on its center welded threaded bolt, suitable for internal thread of the sleeve. The handle should be removable to be able to increase the rod using extension rods.

- The product is coated with anticorrosion agent - primer and oil paint.

Tip: The blade may be formed from a disc of a circular saw. It needs to be cut into two parts grinder.

Recommended set of parts for boranet manufacturers

The diameter of the blades are chosen by the planned size of the well. If the fastener uses the sleeve, the blades can be replaceable.

Two-noise drill

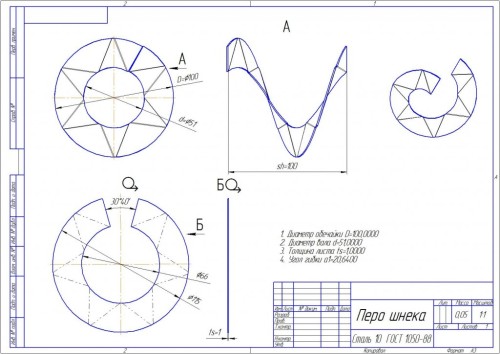

Note: There are storms of a more complex, auger design. Make such a tool more difficult, but its effectiveness is higher. A screw can be purchased at a finished form or make a drawing (see below).

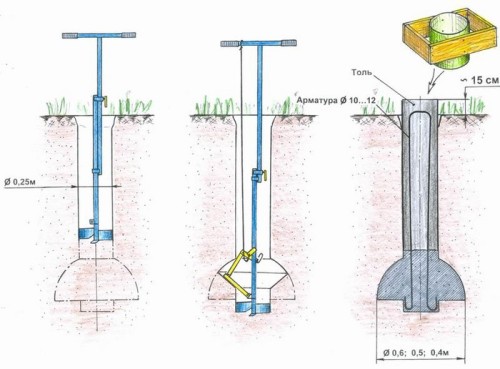

Earth Drive Tiese for foundation piles

For the manufacture of wells under the fill of the pile foundation, it is necessary to buy an earthen burr to buy a type of tees. Its design allows you to prepare deep wells (up to 2.3 m) with a diameter of 250 mm with a lower extension up to 600 mm, thanks to which the columnar base is stable. Extension is obtained using a special folding blade.

Using a burah tees, you can get wells for pouring piles with lower extension

In order to make work with such a tool more efficient, recommendations should be followed.

- At the first stage, the wells are dried, and the extension is performed at the second stage. This reduces the time required to snap the borax by an expansion plow.

- Before proceeding to the drilling of the well, in the ground we take off the pit in a depth of the floor of the shovel.

- The soil with a large sand content will be easier to be easier if you prepare a hole in advance and pour 3-4 water buckets into it.

- During the work of the BUB rotates clockwise.

- It is important that the depth of the base of the future pile is below the level of primer of the soil at least 0.15 m.

- Drilling is carried out in several techniques: the baker must be periodically removed from the well to remove the soil.

In conclusion, we suggest familiarize yourself with the video on how to independently make a handberry manual.