Finishing the foundation panels do it yourself Construction

The foundation of the house is subjected to constant influence of atmospheric phenomena. As a result, his gradual destruction occurs. To prevent this negative process, it is necessary to finish the foundation of the panels (in the photo). Through the use of this technology, the base part of the building will not only be protected, but also more attractive.

Content

Facing materials

The material to be finished the base must be resistant to:

- large temperature differences;

- excessive drying (on hot days) and moisturizing (in rainy weather);

- mechanical load both horizontally and vertically;

- the effects of ultraviolet radiation.

The most suitable materials for the facing of the foundation are:

- plaster;

- stone;

- plastic panels.

Plaster - the cheapest and simple option. After cleaning the surface to it, the grid for reinforcement is attached, plastering is made. Due to the variety of plaster mixes in color and texture, it will not be difficult to acquire the necessary material. Disadvantages of plastering - the probability of cracking after several years and low aesthetic properties.

Natural stone refers to the most beautiful decoration of the base. Granite, marble or sandstone will make the foundation of the house very stylish and modern. But the facing of natural stone is quite expensive pleasure.

In many respects, artificial material compares with natural stone. It is also resistant to sunlight and shocks. Artificial stone of frostons and durable. The only "minus" lies in the fact that when the moisture is inserted under the material, the facing is being destructed. Therefore, special attention is paid to the qualitative conduct of waterproofing work.

Plastic panels are used with the greatest demand in our days for cladding base. An acceptable price for finishing the foundation of panels, the imitation of any material, simplicity of installation, low weight, the insensitiveness of the reinforcement, resistance to the negative impact of the natural environment, solid operational period - all these characteristics are inherent in plastic products.

Installation technology plastic panels suggests:

- conducting a preparatory stage;

- frame device;

- laying thermal insulation material;

- fixing panels.

Preparatory stage

At this stage it is necessary:

- carry out the correct measurements of the trimmed base;

- determine the exact amount of facing material and framework elements (rails, slats, galvanized profile, suspensions, screws);

- purchase plastic panels for finishing the foundation, fasteners, waterproofing and thermal insulation;

- prepare a building tool: screwdriver, perforator with nozzles, hacksaw, roulette, level, marker, square.

The purchased panels must be designed to cover the base. Polymer products that are separated by the inner walls are uniquely not suitable. This is due to the fact that they have a smaller thickness and are not resistant to frequent mechanical loads.

As for the surface of the base, it should simply be cleaned of dust and dirt. If necessary, remove the old trim. In order to prevent the occurrence of fungus or mold, the base is coated with an antibacterial primer mixture.

Creating a carcass

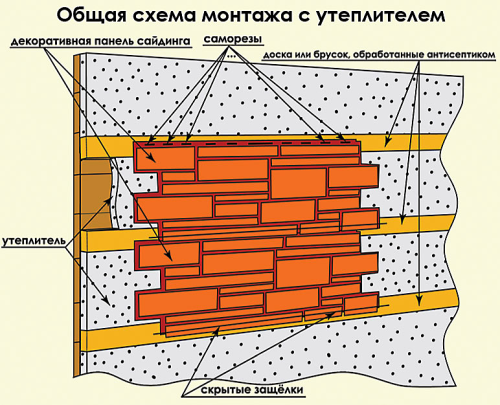

For the manufacture of the crate, you can use both wooden slats and galvanized profiles. Wood must be impregnated with antiseptic. Due to the fact that it is often racks of wood have different sizes, it is better to use metal profiles. The process of the framework of the frame for plastic panels is largely similar to the creation creates for plasterboard.

The fixation of the starting plank, which is actually the bottom of the crate, is carried out at a distance of 40-50 mm from the ground surface. To finish the foundation by plastic panels, it is better to make a frame in a horizontal plane. In the corners, there are angular planks and j-profiles near the openings, communications and protrusions at home.

The fastening of profiles occurs directly to the base of the building with the help of a dowel. In the implementation of this process, it is necessary to constantly check the correct location of the elements of the crate of vertical and horizontal. There should be no distortion.

If the base is additionally insulated, then there should be a space between the wall and framework, which will be enough for laying the heat-insulating material. When using mineral wool, it is still necessary to make a gap, due to which effective ventilation will be carried out.

Insulating work

As a heater, you can use any heat insulating material. But experts recommend using mineral wool or polystyrene foam. Due to the thermal insulation, the foundation of the house will be additionally protected from the exposure to the external environment.

Installation of the insulation is made without junctions. Related plates fit to each other. Reliable fastening of thermal insulation material to the basement is carried out with the help of plastic dowel-umbrellas.

On top of the frame with insulation, the waterproofing material can be fixed. It is quite suitable for the usual polyethylene film. At this preliminary stage of finishing the foundation, the panels ends.

Fastening plastic panels

The first panel is attached to the starting bar. The fixation of each panel is carried out at four points: in two - in the middle part, in two - along the edges of the material.

Screwing the screws occurs in the center of the slot panels. Fasters should not be screwed up to the stop (the gap should be within 1 mm), since plastic panels are capable of expanding at temperature fluctuations.

Another one of the inalienable requirements of the finishing of the foundation panels is the location of the following row of material with a displacement of up to 0.3 m. That is, plastic panels are mounted in a checker order, as happens brickwork.

If small gaps are formed in the process of laying a facing material, they can be seen by silicone sealant of the same color. To cut the panels use hacksaw.

After installing the last row of panels, the upper part of the foundation of the house is closed with a plastic sampling. It will not allow moisture penetration into the inside of the skin with a strong rain.

Video about the finishing of the foundation panels: