Solid fuel boilers: installation instructions Climate

Installation of a solid-fuel boiler for the heating of a private house or an apartment is a responsible task that does not tolerate even the slightest deviations from instructions. The established rules guarantee safe, efficient and durable equipment. Here you will find all the necessary information that will help you personally mount a solid fuel boiler in your home.

Content

How to choose a boiler

Before you begin to describe the installation, we suggest to talk about the very subject of research - solid fuel boilers and their views. The market presents many types of heating boilers depending on the fuel on which they work: gas, electricity, firewood, coal, etc. The difference in solid fuel boilers is hidden in the title - they work on solid fuel (mainly on the corner and wood), and their main advantage is precisely in this, since other energy sources are uncontrollably expensive every year. Solid fuels also change in price, but still remains the cheapest and affordable as compared to the gas and even more electricity.

Buy a solid fuel boiler for long burning can be used for different applications, ranging from the heating of a small room or a residential building, ending with industrial use. Such a heating system will be the perfect option for owners of private houses that are engaged in woodworking or live next door to such enterprises, where you can get wood waste at any time. It is also almost the only available option for those cases when there is nothing nearby at all, it is impossible to supply gas or electricity, or it is too expensive.

What are the boilers on solid fuel:

- Classic - in such boilers there is a temperature sensor that controls the grate grid, thereby controlling the temperature inside. When the temperature in the water solid fuel boiler drops, the sensor opens the damper and admits oxygen, which displays the fuel. On one boot, such a boiler may burn 2-7 hours. Of the obvious advantages, you can highlight a low cost, a simple and reliable design, proven over the years, as well as the ability to lay different fuel. Unfortunately, this technique has a very low efficiency, it is extremely sensitive to the humidity of fuel and does not allow to adjust the temperature of the coolant.

- Long burning - depending on fuel, such aggregates can be coal, coke, wood, peat, brown, etc. Those that use only wood differ from other long-burning boilers, in which the furnace is equipped with more heat-resistant parts that optimize the combustion of fuel and the original oxygen supply system. The most important advantage of such boilers is how to understand from the name, for a long time of operation on one load - up to 6 days. On wood fuel they work less, but still longer than classic - up to 2 days. However, the efficiency does not even exceed 80% at the same time, you cannot regulate the temperature of the coolant, and the loadable fuel should be dry. You should also know about the specifics of the cyclical work of the boilers: first you load the fuel, it burns, fades, then you must clean the boiler and only after that you can download a new batch again. Therefore, if you are going to buy such equipment, prepare for weekly cleaning. You can not exhaust fuel during combustion.

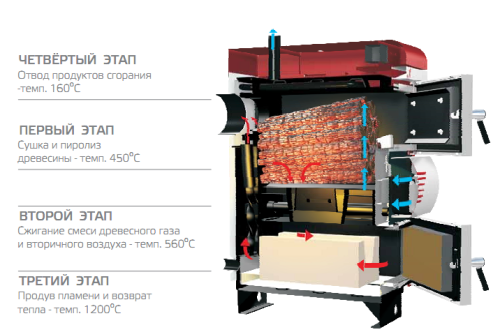

- Pyrolysis - their main distinguishing feature is that it is not fuel itself, but gas that is distinguished by wood materials at high temperature. As a result of such a combustion technology, soot and ashes are practically not formed, and the efficiency reaches 85%. On one load, the pyrolysis solid fuel boiler is capable of working up to 12 hours, but it only needs high-quality dry raw materials, especially if there is no lining of the combustion chamber. If the lining is insufficient, the walls will quickly run, and the technique will fail. One of the disadvantages is the need to use the power grid.

- On pellots - a solid-fuel boiler for the house on pellets is rarely used, but its popularity is just beginning to gain momentum. The reason for this is the so far the emerging business of manufacturing and implementing pellets - woodworking waste, compressed in granules with a length of 5-7 cm and a thickness of up to 10 mm. One boiler loading pellets, and it will dump from 2 to 15 days depending on the volume of its fuel compartment. At the same time, the technique gives high efficiency, you can adjust the burning intensity, the fuel is packaged in convenient packages (there are no problems with transportation and storage). Unfortunately, today pellet boilers and fuel are fairly expensive because of the lowest prevalence, but completely pay off for the first couple of years.

General Installation Requirements

From year to year, climatic conditions in the whole world undergo significant changes that do not remain unnoticed. And for the most part, these temperature moves lead to an increase in cold days a year, which means it's time to think about installing a full-fledged, convenient and durable heating system. First of all, it should be understood that solid fuel boilers of heating are a specific technique, working with which requires certain knowledge and skills. However, even if you are not going to install such a boiler, it is recommended that you can study the principle of operation and all kinds of nuances of operation in the future in order to carry out the service on your own, and not spend money on a master call.

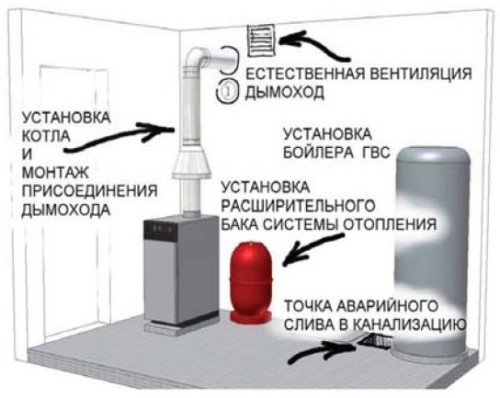

Choosing a place

The choice of the installation site of a solid fuel boiler depends on its constructive and operational features. Traditionally, it is necessary to equip a special room for this - floppy, however, it happens that the places in it lacks due to the already existing gas, electric or other boiler. In this case, the unit can be installed in a frame extension, covered with sandwich panels or gloves with fire-resistant insulation, such as stone cotton. This option is extremely convenient for coal boilers whose service is not without dirt.

Any inexpensive low-power solid fuel boiler for home can be installed directly on the floor or screed. Due to low weight, such a technique cannot give serious vibration loads on the base. For boilers, the power of which goes beyond the mark of 50 kW already required the foundation from concrete or booton. The same applies to boilers of long burning with mechanisms for the supply of heavy loads. It is necessary to dig a hole and make a drain pillow from sand and crushed stone. The foundation should rise above the level of the draft screed by 8-10 cm, but it is impossible to bind it with the foundation at home itself.

Houses of houses in most cases include the smoking arrangement for a solid fuel boiler. This is usually a mine inside the wall that leaves the pipe through the roof. If there are no mines or its previously installed gas heating system, it is necessary to mount a separate chimney from metal double-gray insulated pipes. They differ as low weight, and the entire system can be easily assembled independently from individual sections, just like a constructor. The collected chimney in the end is attached to the outer wall of the house.

Requirements and regulations

As for the requirements and standards for the installation of a solid fuel boiler and the entire heating system, on how strictly you will adhere to them, not only the safety and convenience of operation, but also the durability of the technique itself.

What conditions need to be created that the boiler worked as efficiently as possible and long:

- The area of \u200b\u200bthe room where the boiler will be, should be at least 7m².

- In the room it is necessary to equip the powerful ventilation system of the supply and exhaust type with a channel cross section at the rate of 80 mm / 1 kW. More details about the device of the ventilation system in the boiler room is described in the article " Ventilation boiler house in the house».

- There should be no less than half a meter between the outer walls of the boiler and the walls of the room, while the walls should be made of fire-resistant material (it is desirable to accove the angle in which the boiler will be, metal sheets or panels, and drywall).

- Paul also need to be bled by fire-resistant material, and around the boiler itself for 30-50 cm in all directions it is better to make a metal or stone.

It is worth noting that most of the indicators are not axioms and are calculated in accordance with the technical characteristics of the boiler, which can be viewed in the documentation attached to it.

Connection scheme

There are many schemes of solid fuel boilers, but to understand how to connect one or another model, it is enough to be aware of the principle of operation of the technique. To calculate the ideal heating scheme, it is necessary to combine the operation of a solid fuel boiler with accumulatory energy. The bottom line is that the working temperature of the water-drilling unit all the time varies from 60s to 90 ° C and keep this value at some constant mark is almost impossible, since the heating equipment on firewood or coal is an inert device, unlike diesel, gas or electric.

Connecting a solid fuel boiler system as follows:

- At first, all parts of the system must be prepared for installation, equip a boiler room, foundation, if necessary, or a platform from refractory material. If there is little free space in the boiler room, the boiler assembly is produced on the street.

- Next, the boiler put on the foundation or gender so that the power supply pipe is located at one level with chimney. To do this, it will be necessary to enlist the support, as the weight of the equipment usually exceeds 50 kg, and it must be fixed to fix it without distortion.

- Then there is the most difficult part of the work - the blockage of a solid fuel boiler. Connect communications: a pipe for the supply of cold water into the system and a pipe for leading the heated fluid, an additional equipment (expansion tank) is tied for a double-circuit boiler. Several ways of strapping are described slightly below.

- Next, shut down the chimney.

- Produce test running equipment.

Important: When independently installing heating equipment should not count on warranty service from the seller. Most companies are guaranteed only if their employees were engaged in the installation, and therefore it is confident that no installation requirement was broken.

When using the boiler, consider that the efficiency will depend entirely on the quality of the fuel, the correctness of the calculation of the chimney diameter, as well as the features of its design (round cross-section or rectangular, the number of bends, length, etc.). To put the boiler in a poorly insulated house and hope for its effectiveness is meaningless, so pay special attention to the enhancement of the thermal insulation of the walls, gender and especially the roofs. The productivity and reliability of the boiler also affects the diameter of the heating pipes - than it is greater, the smaller the risk of overheating.

Self-scheme

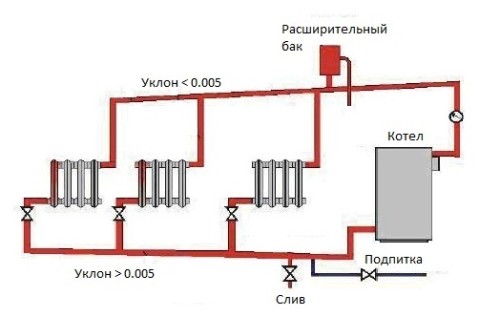

The simplest circuit in the installation of solid fuel boilers is to connect them to the samotane heating system.

In this case, the feed and reverse tubes are directly connected to the outlet nozzles. At the outlet of the boiler attach the air vent, safety valve and pressure gauge. It is important that there is no shut-off reinforcement between them and the outlet. Expansion tank is installed above the heating system. For one-story house, this can be done in the furnace, for a two-story - in the attic.

It should be understood that this is a very conventional equipment installation scheme, and the system will be more effective if the boiler will be located below the level of heating batteries. In some cases, for this in the screed make a recess under the boiler. The main advantage of this system is the autonomy of work and independence from electricity. The scheme is optimal for traditional bottom burning boilers without any superchargers and automation.

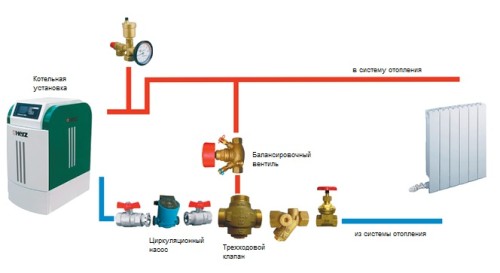

Forced circulation

Heating systems with a circulation pump are inconvenient in that in the case of de-energization, temperature jumps will be observed, which damages harm combustion chambers. For this reason, the strapping scheme is obliged to include the primary contour with a three-way valve.

As can be seen in the image above, the valve controls the water temperature in the return pipe. As a result, the cold water does not rush into the boiler, and slowly mixes with the coolant, which circulates in a small circle. To change the system settings, the balancing valve is used here.

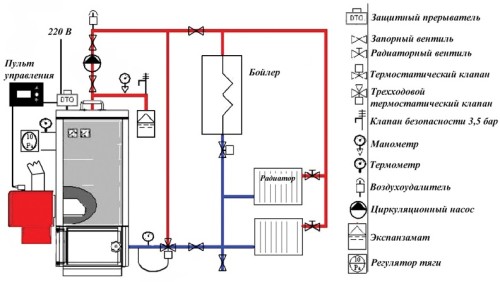

Recently, for supplying DHW, the technique of heating water from the coolant is increasingly used, which circulates in the system. Small private houses with several branches of radiator heating can be advised by the connection scheme with an indirect heating boiler, which is shown below:

The boiler is connected in parallel with heating branches immediately after the first circuit, which ensures the selection of the hot heat carrier to heat the fluid on the DHW. At the output, you can see the passage of thermal valve, which does not give hot water to flow through the heat exchanger. It is opened only when the temperature of the coolant decreases to a certain level, which is possible only when using the DHW.

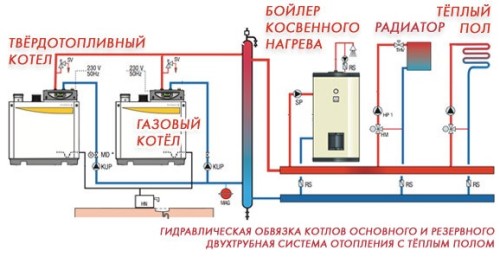

If the house is large, and it has several boilers operating on various types of fuel with radiators, wall panels and warm floors, it is necessary to use a more complex pattern of strapping.

In this case, for the correct installation of the boiler, it is necessary to connect it to the thermal battery along with the electric heater. Each of the heat sources is equipped with its own circulating pump controlled by a boiler controller. At the same time, water in the primary circuit moves solely as needed. On the other consumers, including the boiler, also installed their own pumps. They can function continuously, but it often happens by means of an electronic unit controlling both hot water consumption and the climate in the house.

The heating of the house is a solid fuel boiler is a rational solution and a wise investment in your own future and the future of your home, but the installation of such equipment is often frighteningly expensive. If you want to save, but at the same time not to sacrifice quality and security, carefully examine all available connection schemes and, if possible, consult with specialists.