Ventilation boiler house in the house Climate

Design and calculation of ventilation boiler house is not only the key to the long and productive work of heating equipment, but also guaranteed the safety of tenants. If you neglect such an important aspect, it can lead to carbon monoxide poisoning. There are several ways to ensure air movement in the boiler room, and the choice depends on the characteristics of the equipment. In this article, we consider the main points of the ventilation device boiler room.

Content

Requirements for ventilation

In the process of operation of any boiler equipment, there is incineration of any fuel - gas, firewood, chips, gasoline, etc. As is known, oxygen is intensively consumed during the burning, and the boiler literally like a vacuum cleaner sucks a large amount of air. If not to ensure the arrival of fresh air masses from the outside, the combustion will not be so intense, and the carbon monoxide will fill all the free space in time. That is why it is so important to equip the boiler ventilation system.

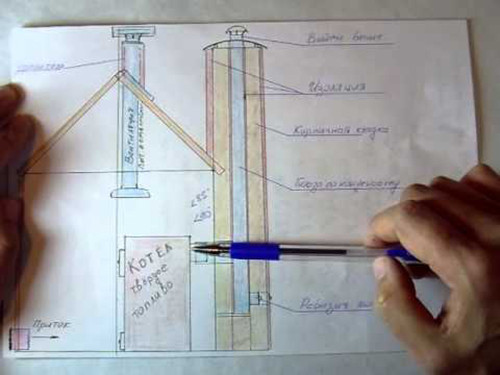

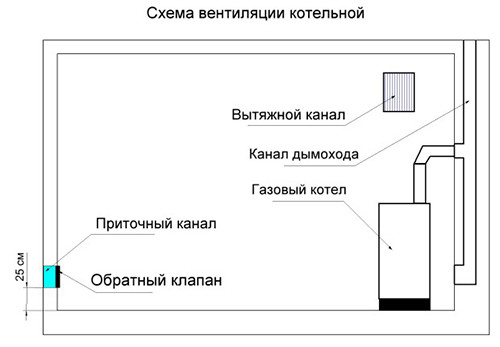

Any work should be started with planning, and for this you should know the basic requirements and rules for the installation and use of equipment. The ventilation scheme should display all the smallest details so that in the process of installation does not occur unexpected problems. The main task of the ventilation system is to prevent feedback and do not allow carbon monoxide to break through the residential premises.

As we said, choosing a ventilation method depends on the equipment used, but there are general requirements for any boiler:

- The ventilation of the boiler should be adjacent to the main air-powered system of the house.

- The ceiling must be equipped with an air channel.

- In the wall there must be two chimney channels: the first - for the chimney, the second, located under it and a diameter of at least 25 cm - for the solid service of the chimney.

- Clean air can come directly from the street or through the grille in the inlet door to the boiler room.

- The openings for the flow of oxygen should be calculated on the basis of 8 cm² per 1 kW of the heating unit if the air comes from the street. If the inflow from the inside, the holes should be at least 30 cm² per 1 kW.

- When calculating, use the documentation for boiler equipment.

If a sufficiently low-power gas boiler is up to 30 kW for heating your home, then according to SNiP for it, it is absolutely necessary to equip a separate room. It can be installed even in the kitchen if its area is not less than 15 m², and the height from the floor to the ceiling is at least 2.2 m. In this case, the supply and exhaust ventilation system is suitable. In the kitchen or indoors, where you are going to install a gas boiler, the glazing area should be at least 0.3 m² per 1 m³ of room volume, and windows must be present in the windows. Also for a gas boiler will be needed to make air intake openings with a total area of \u200b\u200bno less than 25 cm² to provide a regular influx of fresh air. It is best to have a boiler near the walls covered with non-combustible material, but in any case, the distance between the wall and the equipment should be 10 cm. If there was no wall covered with a non-combustible finish throughout the room, the boiler can be installed near the plastered wooden wall, covered with a heat transfer shield from Sheet metal.

If you need a gas boiler, the power of which exceeds 30 kW, then for it will have to take a separate room. Requirements for the premises depend on its location. We suggest to consider a couple of the most common options.

So, make a boiler room, working on natural gas anywhere, including an attic room, but:

- Boiler room must have a separate way out.

- It should have natural lighting. If it is a attic, then there should be attic or ordinary windows.

- The volume of the room (not to be confused with the area) should be at least 15 m³.

- In the boiler room there must be a supply and exhaust ventilation, providing a three-fold air update per hour.

- Related from the boiler room should have walls from fire-resistant materials.

If the boiler room is located outside the house, its use is more convenient, safe and profitable. In addition, you will not hear the noise of the equipment and you can save a useful living area. Separately standing boiler should be located on its own foundation, that is, its base should not be connected to the foundation of the house or other buildings on the site. The heating installation must be located above the floor level, but not more than 15 cm. Well, and, of course, the walls and roof of the furnace should be made of fireproof materials.

Ventilation calculation

Competently compiled project ventilation boiler room - a pledge of its effective work. The full scheme may include a large number of parameters, ranging from a detailed plan of the room, ending with the characteristics of the equipment. However, for household ordinary boilers, such a difficult calculation is not at all. You can only be limited to the following parameters:

- Volume of boiler room.

- The speed of the inflow of air masses (not less than 1 m / s).

- The radiation ratio of the air exchange (depends on the distance between the floor and the ceiling).

The above characteristics are needed in order to correctly calculate the right air intake channel diameter. For example, we make a calculation for a room with a length of 4 m, 3 m wide and with a ceiling with a height of 2.7 m. The room volume is 32, 4 m³.

To calculate the multiplicity of air exchange, we produce the following calculation: (6-2.7) * 0.25 + 3 \u003d 3.8.

32.4 * 3.8 \u003d 123 m³

Thus, 1 hour with natural ventilation is 123 cubic meters of air.

Having this data, you can calculate the diameter of the air channel:

123/3600 \u003d 0.034 m²

Since for ventilation, the pipes with a circular cross section are usually installed, it will be more reasonable to translate this value from the area to the diameter - 204 mm. There are no pipes with such a diameter, but the closest size that can be found in the store is 200 mm.

We calculated the air intake channel through which the exhaust air will be leaving, the supply hole must have the corresponding parameters. In the event that in the boiler room there is already a air mine with a diameter less than the calculated, it is better to make forced ventilation. Usually, a conventional fan is used for this, the power of which fills the lack of efficiency of the natural system.

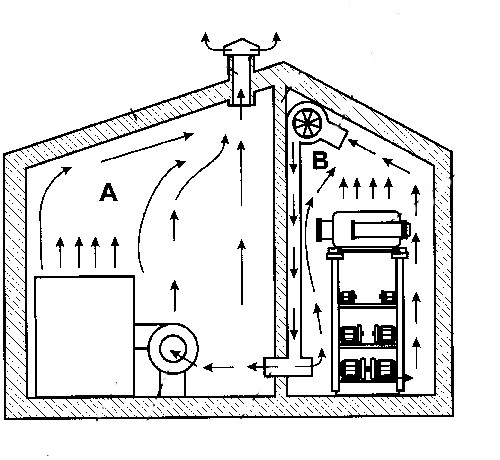

Types of ventilation systems

As you know, ventilation may be natural and artificial. In the first case, the air movement occurs due to the difference in pressure inside the boiler room and outside. Air masses from the high pressure region are moving to the low area. Make such ventilation gas boiler with equipment up to 30 kW is very simple. To do this, at 20-30 cm from the floor in the wall or door they make a hole with a diameter of 100-150 mm. In this hole, the plastic tube is inserted and covered its outlet of the fine mesh so that insects and garbage insect. From the other end of the pipe, the check valve is installed, which does not allow the air to go out, and only pours it inside. The exhaust hole is shutd up in the same way, only without a valve.

Useful Tip: Supply pipe output Better to bring closer to the fuel compartment so that fresh air immediately entered the camera and improved burning. However, direct the air flow directly into the boiler is strictly prohibited! And the exhaust hole will be perfectly looked right over the boiler, then the combustion products will immediately fly out, and not "walk" on the boiler room.

The lack of natural ventilation is that you cannot control the circulation of air, and its intensity for the most part depends on the weather and temperatures on the street.

As for forced (artificial) ventilation, it can be put in addition to natural or in itself. In a good way for powerful boilers, it is better to set exactly such a system with two fans: exhaust and intimidate. Productivity of fans should be chosen in accordance with the requirements of a three-time air exchange indoor. Measure the width, height and length of the cooler, multiply these numbers to find out the internal volume. Then multiply it to 3 and find the amount of air to run and output the fans. The housings for them must be made of sheet metal so that the random spark does not create a fire-hazardous situation.

To reduce power consumption, you must connect the ventilation system to the boiler so that it does not work "dry", and started along with heating equipment. Forced exhaust ventilation boiler store saves on all calculations.

Chimney

Chimney is an integral component of the ventilation scheme of a boiler house of a private house. It must also comply with certain requirements, on the accuracy of which the safe and efficient functioning of the equipment depends.

Requirements for the arrangement of the chimney in the boiler room:

- Choose a chimney cross-section in accordance with the passport data of the boiler.

- The diameter of the withdrawal tube must be equal to the value indicated in the characteristics of the boiler.

- The chimney should be located at no lower level of the roof of the roof and climb over it for several meters.

- The chimney itself should be made of metal.

- The chimney must be holes for cleaning and maintenance.

- Ideally, the chimney should be direct, but no more than three bends are allowed.

Installation

Before starting the installation of the boiler room, it is necessary to correctly pick up equipment for it. The chapter will stand the boiler, and it is necessary to choose it in accordance with the total volume of all the premises to be heated. It should also be considered the features of the climatic zone in which you live. More information on this topic can be found in the article " Calculation of boiler power».

However, the boiler will not work by itself, and it is necessary to buy additional equipment. The selection of auxiliary devices occurs depending on the power of the heating equipment and its parameters. So you can calculate the necessary capacity of the expansion tank, the performance of the pump, etc.

Installation of ventilation should be made after mounting all parts of the heating unit. How to install gas equipment Read in the article " Installation of a gas boiler with your own hands" Air pipes can be fixed in a horizontal or vertical position - as more convenient. But in order to ensure efficient system operation, some conditions should be followed. So, horizontally, you can put pipes only for the ventilation of the forced type. They must be straight, without bends and turns. The maximum length of such a pipe depends on the power of the boiler. Vertical air bodies are installed with natural ventilation, while they should not be shorter than 3 m to ensure due trave.

It is best to make a combined ventilation system with horizontal and vertical air pipes in case the forced system fails, natural at least somehow can compensate for its operation.

Regardless of your chosen system, the ventilation requirement in the boiler room must be observed strictly. The main rule: how many exhausted air left, so much fresh should go to the boiler room.

Let's summarize. The location of all components of the ventilation system should be determined by the characteristics of the heating equipment. The influx of air should be closer to the working furnace area, but you should not direct the air directly to the furnace. The distance between the supply and exhaust holes should be maximum permissible. If you are going to install a solid fuel boiler, it will take additional compulsory ventilation at the site of the appearance of soot.

Calculation and improvement of ventilation boiler house in the house is a very painstaking job. If the project provides for the use of a boiler with high power or even several boilers, it will be the most reasonable to use the services of specialists and do not take a complex ventilation on their own. In some cases, the ventilation system requires the installation of devices for cleaning air from toxic gases. The choice and installation of such filters is better to trust professionals.