Mounting foam: composition and specifications Building materials

Mounting foam is one of the most popular modern building materials. It is widely used in all directions of construction and repair work to seal seams, to improve the hydro and noise insulating properties of various structures and rooms. But that the result of any work was high-quality, you need to know which types of mounting foams are what they differ and what properties possess. All of this you will learn from this article.

Content

Composition of mounting foam

Before you buy a mounting foam, you need to decide what exactly you need and what level of professional skills is inherent.

In terms of composition, assembly foam distinguish:

- Single-component - ready-to-use mixture is in a cylinder under pressure. In the market, such a kind is represented by polyurethane foam mounting foam.

- Two-component - such compositions are used primarily highly qualified masters for industrial purposes. The basic condition for proper use is a clear observance of the proportions in the manufacture of the mixture.

Important! Most often used mounting foam of the first type, as it is more convenient and easy to use. A complete set of substances of such a mixture includes:

- polyol, isocionate - prepurates that are the basis;

- clean gas - a mixture of Bhutan and Propane;

- flushing substances are stabilizers, catalysts, elements that increase adhesion and regulating the degree of foaming of the mass.

Properties of mounting foam

The high performance of the mounting foam is due to its properties that are advantages - this is:

- High degree of adhesion with materials of any type - wood, plastic, metal, stone, polymer compositions.

- Heat resistance - Standard indicators of maintaining source properties are -45 / + 90 ° C.

- Independence of electric current.

- High grasp and frost speed - from 8 minutes to 24 hours.

- Absolute attaching after final polymerization.

- Nonbitating - characteristic of some types of mounting foam.

- Beautiful moisture resistance.

- Plasticity in combination with elasticity, which provides the most dense filling of all the slots and joints, and also prevents destruction by rupture

- Low thermal conductivity.

- Shrinkage no more than 5% over the entire period of operation.

- The optimal density for solving various tasks is from 1525 to 2525 kg / m3.

- Chemical resistance.

- High strength - an indicator for compression is usually within 3-5 H / cm2.

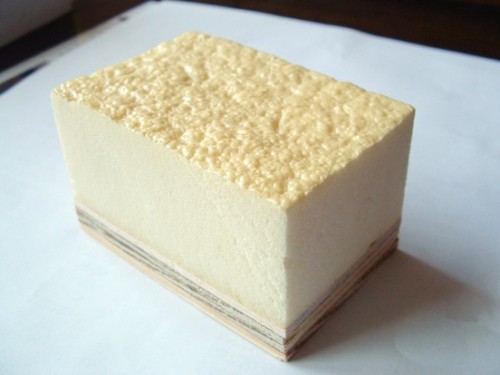

Important! An indicator of high-quality mounting foam is first of all an external sign - its color. It should be a light yellow or greenish shade.

Important technical characteristics of mounting foam

Almost all of the above properties indicators are indicated by the manufacturer on the package. In addition, there are several more technical characteristics that determine the quality of this building mixture.

Expansion of foam

The volume of expansion of the foam affects its filling ability, on the quality of the sealing seam and its elasticity. This process takes place twice:

- during the exit of the mixture of the cylinder;

- during frozen.

Important! It is the secondary expansion that is more important to the quality of the seal of the desired part of the structure.

Depending on the type of mounting foam and a specific brand, expansion indicators can be:

- 10-60% - for household type mounting foam

- 180-300% - for professional mounting foam.

Viscosity of mounting foam

The quality of sealing of the mounting foam vertical surfaces directly depends on the degree of its viscosity - the higher it is, the better it will be captured with the surface and the less it will crawl.

Important! Check the flow of the flow of the mounting foam can only after opening the cylinder. To protect yourself from a defective or poor-quality goods, professional masters acquire products only well-proven themselves, proven brands.

Volume of mounting foam

There are several standard forms of the installation of mounting foam, which differ precisely volume of the container. In the market you will find cylinders with mounting foam from any manufacturer with the following parameters:

- 300 ml, at the output of which about 30 liters of the finished substance are obtained;

- 500 ml - at the exit give up to 40 liters of mounting foam, ready to use;

- 750 ml - the volume of this mounting foam is up to 50 liters;

- 1000 ml is a professional mounting foam, a volume of 80-100 liters of which is enough to solve large-scale tasks.

Types of mounting pen

All types of mounting Pen differ in several criteria.

Mode of application

This is the principle vary:

- Professional mounting foam. Material cylinders are inserted into a special building gun, which the desired amount of the mixture is given to the portion. It is convenient for its use due to the ergonomics of the handle, as well as the dispenser curly. The main condition for the long life of such a tool is its timely flushing, after each use.

- Semi-professional. Such a material is sprayed from a special tube from plastic, which dresses on the pressure lever. More suitable for solving minor repair tasks.

Temperature application

Depending on where exactly and at what time of year it is planned to apply a mounting foam, it is necessary to decide on a suitable type of mixture. In the temperature range, mounting foam differences are distinguished:

- summer - have indicators + 5-35 ° C;

- winter - range is -18 / + 35 ° C;

- universal - the scatter of permissible temperatures is -10 / + 35 ° C.

Important! These characteristics belong to the temperature of the treated surfaces, and not air. When determining the consumption of the mounting foam, it is necessary to consider: the lower the temperature, the smaller the volume of the mounting foam will be at the outlet of the cylinder.

Degree of flammability

The degree of flammability of the mounting foam is indicated on the cylinder necessarily. It is determined by the class. The market presents such types of mounting foam:

- B1 - refractory mounting foam;

- B2 - self-fighting;

- B3 - combustible mounting foam.

Popular manufacturers

To buy high-quality mounting foam, give preference to proven manufacturers. To date, such brands are considered the best according to professional builders:

- Soudal. Belgian trademark, under which almost 50 years already produced a wide line of various high-quality building mixtures.

- Penosil. The inexpensive Estonian brand, among the products of which you will find not only the mounting foam, but also other building mixes to solve various tasks. Good price-quality ratio create resistant popularity of the brand Penosil.

- Tytan. Acceptable by the price of Polish products, the high quality of which is invariably inherent in all products of this manufacturer. TYTAN mounting foams are distinguished by excellent viscosity, optimal expansion and long service life.

- Ceresit. The German company, which since the beginning of the 20th century has gained popularity in the construction market. Products of this brand is a reference standard in all world countries.

Important! Depending on which brand, you will prefer, not only the price of the mounting foam, but also your confidence in its quality and reliability. Therefore, do not seek to save and buy cheaper analogues of unknown manufacturers so that with time your building structures are not deformed, and the quality of sealing remains at the proper level.

Application of mounting foam

Mounting foam is used at all stages of construction work - when sealing the joints of window and door structures, when sealing seams or gluing block materials, and even when installing the bathroom or installation of polystyrene foam insulation.

At home, most often use the mounting foam precisely as a sealant. So that this procedure does not cause you any difficulties, consider the following rules for working with the mounting foam:

- Make a preliminary stripping of the connected or sealed surfaces from any dirt and dust.

- Protect your hands with gloves - when hitting the skin, the composition of the mounting foam is very difficult to wash away, and in some cases it can cause minor allergies.

- Check out the manufacturer's recommendations specified on the cylinder.

- Insert the balloon into the gun.

- Send a jet to the desired surface and fill the seams on 1/3.

- To accelerate the screwdrock, sprinkle the extruded mass with water, since it is precisely under the influence of moisture a mixture polymerization occurs.

- Look out 15-30 minutes, make sure that the full foam expansion occurred.

- If the seams are not filled enough - add some more mixture.

- Wait for full pouring - usually it is 24 hours.

- Sharp the knife cut the surplus foam, aligning the seams.

Important! Very important question - consumption of mounting foam. The answer to it exists in standard construction standards, and for each individual type of work its indicators. In practice, such data may be varied - this factors affect this:

- seam length;

- width and depth of seam;

- the quality of the used mounting foam;

- type of design design.

Since a clear universal response regarding the consumption of mounting foam is not possible, use convenient online calculators to calculate the volume of the construction mixture for your work.

Application of mounting foam - video

Conclusion

Now you know all the most important information about the installation foam. Correctly approach the choice of material, give preference to high-quality products and follow the technology of application, then you do not have to worry about the need for repair work in the next few years.